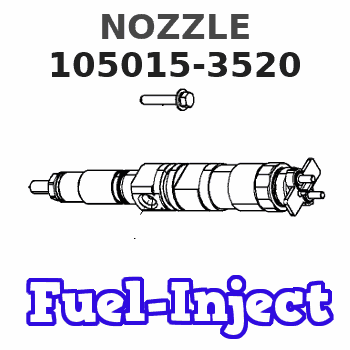

Information nozzle

BOSCH

9 432 610 142

9432610142

ZEXEL

105015-3520

1050153520

ISUZU

1153110730

1153110730

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

BFMSAZEA Diesel Injection Pump Parts Nozzle 105015-3520 Fuel Injector Nozzle Tip Compatible with SN Type DLLA150S384NP73 Compatible with Isuzu 6RA1, 6RA1TC Engine

BFMSAZEA Diesel Injection Pump Parts Nozzle 105015-3520 Fuel Injector Nozzle Tip Compatible with SN Type DLLA150S384NP73 Compatible with ISUZU 6RA1, 6RA1TC Engine || Precise fuel injector nozzle tip for optimal performance || Compatible with SN type DLLA150S384NP73 fuel injector nozzle tip || High-quality diesel injection pump parts nozzle || Durable and long-lasting performance

BFMSAZEA Diesel Injection Pump Parts Nozzle 105015-3520 Fuel Injector Nozzle Tip Compatible with SN Type DLLA150S384NP73 Compatible with ISUZU 6RA1, 6RA1TC Engine || Precise fuel injector nozzle tip for optimal performance || Compatible with SN type DLLA150S384NP73 fuel injector nozzle tip || High-quality diesel injection pump parts nozzle || Durable and long-lasting performance

$48.68

30 Oct 2024

KR: Adabus

Injector Nozzle DLLA150S384NP73 Nozzle 105015-3520 Injector Nozzle Diesel fuelinjecton Sprayer for Isuzu 6RB1/A456

Generic

Generic

You can express buy:

USD 41.99

31-07-2018

31-07-2018

105015-3520 Fuel Injector Nozzle SN Type Automobile Engine Pump Parts Nozzle DLLA150S384NP73 For ISUZU Diesel Engine Injector

USD 41.99

31-07-2018

31-07-2018

Diesel injection pum parts nozzle 105015-3520 SN Type Engine Pump Parts Nozzle DLLA150S384NP73 For ISUZU Fuel engine from China

Include in #1:

106671-1100

as NOZZLE

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

6. No or poor response to throttle

Active Diagnostic Codes: Troubleshoot any active diagnostic codes. ECM: Verify that ECM has completed its start-up self-checks and is out of cold mode. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack.7. Low power/Engine speed (rpm) restricted

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Inlet Air System: Check for plugged air filter, aftercooler restrictions, aftercooler leaks, high inlet air temperature. Inspect all gaskets and piping for leaks. Exhaust System: Check for any restrictions. Fuel Injection Nozzle/Pump: If the engine is misfiring or engine speed (rpm) is restricted, run the engine at the speed where the problem is most pronounced. Momentarily loosen the fuel line nut on the injection pump to "cut out" that cylinder. Check each cylinder in this manner. If one is found where loosening makes no difference in irregular operation, the pump and nozzle for that cylinder should be inspected for damage, wear and proper operation. Inspect components for leaks and replace as needed. Fuel Injection Timing: See your authorized dealer. Valve Lash: Adjust valves to specified clearances. Turbocharger: Check for carbon buildup or restricted movement of turbo wheel. Replace if necessary. Auxiliary Attachments: Inspect, align, tighten and check for excessive parasitic loading. Active Diagnostic Codes: Troubleshoot any active diagnostic codes. Factory Parameters: Verify that Full Load Setting and Full Torque Setting are programmed to the values stamped on the engine information plate. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC.8. Intermittent engine shutdowns or power reduction

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Shutoff Solenoid: Actuate the control that operates the shutoff solenoid and listen for a "clicking" sound. Power Supply to ECM: Check electrical connectors, wiring and voltage from battery to ECM. Power to ECM should measure 22 to 27 volts. Shutoff Solenoid: Check electrical connectors and wiring. Mechanically override the shutoff solenoid by attaching a lever to the fuel pump. Push lever backward to override the solenoid or forward to shutoff fuel supply. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Engine Speed Signal: (Magnetic Pickup) Check electrical connectors and

Active Diagnostic Codes: Troubleshoot any active diagnostic codes. ECM: Verify that ECM has completed its start-up self-checks and is out of cold mode. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack.7. Low power/Engine speed (rpm) restricted

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Inlet Air System: Check for plugged air filter, aftercooler restrictions, aftercooler leaks, high inlet air temperature. Inspect all gaskets and piping for leaks. Exhaust System: Check for any restrictions. Fuel Injection Nozzle/Pump: If the engine is misfiring or engine speed (rpm) is restricted, run the engine at the speed where the problem is most pronounced. Momentarily loosen the fuel line nut on the injection pump to "cut out" that cylinder. Check each cylinder in this manner. If one is found where loosening makes no difference in irregular operation, the pump and nozzle for that cylinder should be inspected for damage, wear and proper operation. Inspect components for leaks and replace as needed. Fuel Injection Timing: See your authorized dealer. Valve Lash: Adjust valves to specified clearances. Turbocharger: Check for carbon buildup or restricted movement of turbo wheel. Replace if necessary. Auxiliary Attachments: Inspect, align, tighten and check for excessive parasitic loading. Active Diagnostic Codes: Troubleshoot any active diagnostic codes. Factory Parameters: Verify that Full Load Setting and Full Torque Setting are programmed to the values stamped on the engine information plate. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Throttle Position Signal: Check electrical connectors and wiring. Supply voltage to sensor should be between 22 and 27 V DC.8. Intermittent engine shutdowns or power reduction

Fuel Supply: Check for empty fuel tank, plugged fuel tank connections, obstructed or kinked fuel suction lines, plugged fuel filter, air in fuel system or kinked, leaking or broken fuel lines. Shutoff Solenoid: Actuate the control that operates the shutoff solenoid and listen for a "clicking" sound. Power Supply to ECM: Check electrical connectors, wiring and voltage from battery to ECM. Power to ECM should measure 22 to 27 volts. Shutoff Solenoid: Check electrical connectors and wiring. Mechanically override the shutoff solenoid by attaching a lever to the fuel pump. Push lever backward to override the solenoid or forward to shutoff fuel supply. Rack Controls: Check electrical connectors and wiring from ECM to rack position sensor and to rack BTM. Measure the signal output to the ECM. Also check for binding of servo or rack. Engine Speed Signal: (Magnetic Pickup) Check electrical connectors and