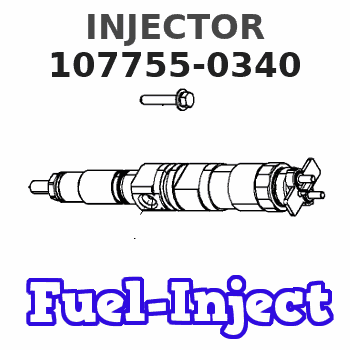

Information injector

BOSCH

F 01G 09P 1H8

f01g09p1h8

ZEXEL

107755-0340

1077550340

MITSUBISHI

ME225190

me225190

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Common Rail Injector 0445120090 ME227600 ME225190 0986435634 Diesel Nozzle Assembly(ME225190)

JHDKDFN OEM NO. : 227600 225190 || Reduce fuel consumption: precise control of fuel injection quantity || Enhanced power: Accurate fuel atomization improves fuel combustion efficiency || Smooth operation: effectively solves problems such as unstable idle and shaking of vehicles || Quick response: The fuel injector responds very quickly, which helps the engine start quickly

JHDKDFN OEM NO. : 227600 225190 || Reduce fuel consumption: precise control of fuel injection quantity || Enhanced power: Accurate fuel atomization improves fuel combustion efficiency || Smooth operation: effectively solves problems such as unstable idle and shaking of vehicles || Quick response: The fuel injector responds very quickly, which helps the engine start quickly

6PCS Control Valve Set F00RJ01428 Diesel Common Rail Injector 0445120048 0445120049 Parts F 00R J01 428 Compatible with MITSUBISHI ME222914, ME223002, ME225190

DICSCL PARCS Premium Quality Material: This product is manufactured using high-quality materials that ensure durability and longevity. || Powerful Functionality: Designed as a control valve set for diesel fuel common rail injectors, this product greatly improves the efficiency and performance of the fuel system. || Designed for Testing: With an advanced valve body test machine design, this product allows for thorough testing and measurement of injector valve body performance and reliability, ensuring it meets the highest standards. || Wide Compatibility: Suitable for various truck parts, specifically designed for relay valve bodies, this product can be used with different models and brands of vehicles. || Hassle-free Installation: The product is intelligently designed for easy installation, reducing installation time and labor costs while ensuring a safe and reliable installation.

DICSCL PARCS Premium Quality Material: This product is manufactured using high-quality materials that ensure durability and longevity. || Powerful Functionality: Designed as a control valve set for diesel fuel common rail injectors, this product greatly improves the efficiency and performance of the fuel system. || Designed for Testing: With an advanced valve body test machine design, this product allows for thorough testing and measurement of injector valve body performance and reliability, ensuring it meets the highest standards. || Wide Compatibility: Suitable for various truck parts, specifically designed for relay valve bodies, this product can be used with different models and brands of vehicles. || Hassle-free Installation: The product is intelligently designed for easy installation, reducing installation time and labor costs while ensuring a safe and reliable installation.

0445120090 Common Rail Diesel Injector 0 445 120 090 Compatible For FUSO 4M50-TE ENGINE 0986435634 ME227600 ME225190 107755-0341

DGJFPLOU Simple installation: Without professional technology and complex tools, it can be adjusted according to the actual situation to better meet your needs. || Two years warranty: Each injector is manufactured with high precision to ensure the accuracy and stability of the injection, and two years of quality guarantee. || Efficient performance: It can provide your vehicle with more accurate and efficient fuel injection, significantly improving engine power output and fuel economy. || High-quality materials: After strict quality testing and durability testing, it can work stably in the face of various complex driving environments and escort your travel. || 0445120090 Common Rail Diesel Injector 0 445 120 090 Compatible for FUSO 4M50-TE ENGINE 0986435634 ME227600 ME225190 107755-0341.

DGJFPLOU Simple installation: Without professional technology and complex tools, it can be adjusted according to the actual situation to better meet your needs. || Two years warranty: Each injector is manufactured with high precision to ensure the accuracy and stability of the injection, and two years of quality guarantee. || Efficient performance: It can provide your vehicle with more accurate and efficient fuel injection, significantly improving engine power output and fuel economy. || High-quality materials: After strict quality testing and durability testing, it can work stably in the face of various complex driving environments and escort your travel. || 0445120090 Common Rail Diesel Injector 0 445 120 090 Compatible for FUSO 4M50-TE ENGINE 0986435634 ME227600 ME225190 107755-0341.

You can express buy:

USD 638.96

14-06-2025

14-06-2025

0445120090 NEW DIESEL FUEL INJECTOR 0 445 120 090 INJECTION NOZZLE 0445 120 090 for Mitsubishi Mercedes-Benz ME227600 ME225190

USD 159.99

19-05-2025

19-05-2025

0445 120 090 0445120090 Engine Injector 0 445 120 090 Diesel Parts Fuel Injector ME227600 ME225190 for MITSUBISHI MERCEDES-BENZ

Images:

USD 638.96

[13-May-2025]

USD 159.99

[13-May-2025]

USD 159.99

[13-May-2025]

USD 638.96

[13-May-2025]

Cross reference number

Zexel num

Bosch num

Firm num

Name

107755-0340

F 01G 09P 1H8

ME225190 MITSUBISHI

INJECTOR

A C 55KJ

A C 55KJ

Information:

It is not necessary to remove the cylinder head assembly for removal of the camshaft.3. Wire the cam roller followers up off of the camshaft as shown. Do this at each cylinder.

Typical Example3. Remove thrust pin (1), and remove camshaft assembly (2) from the engine. The following steps are for the installation of the camshaft assembly.4. Be sure the camshaft assembly is thoroughly clean. Put clean engine oil on the lobes and journals of the camshaft assembly. When installing the camshaft, rotating it in both clockwise and counterclockwise directions will help prevent it from binding in the bearing bores.5. Carefully install camshaft assembly (2) in the engine.

Camshaft Timing

When installing the camshaft assembly, be sure the number one cylinder is at (TDC) top dead center of the compression stroke with the timing pin installed in the flywheel. Camshaft timing is very important. The timing mark on the camshaft drive gear must line up with the idler gear timing mark as shown in the illustration. For more information about timing of engine, refer to the "Specifications" module, Form No. SENR5560.

6. With the camshaft properly timed and positioned, install thrust pin (1). Tighten thrust pin (1) to a torque of 48 7 N m (35 5 lb ft). Remove the wires that were used to hold the cam roller followers up off of the camshaft.End By:a. install front housing groupb. install speed/timing sensorc. install vibration damper and pulleyd. install alternatore. install drive belt and belt tightener groupf. install fuel transfer pumpg. install electronic unit injectorsh. install rocker arm assemblies and push rodsDisassemble & Assemble Camshaft Assembly

Start By:a. remove camshaft assembly1. Wrap camshaft portion of camshaft assembly with paper towels to protect the camshaft from being damaged.

Care must be taken not to allow the camshaft to fall to the floor when pressing it from the drive gear. Also, be sure that a camshaft lobe does not catch on the press plates.

2. Place the camshaft assembly in a press. Press camshaft (3) from drive gear (1).3. Remove woodruff key (2) from the camshaft. The following steps are for the assembly of the camshaft and the gear assembly.4. Install woodruff key (2) in the camshaft.5. Heat drive gear (1) to a maximum temperature of 300 C (572 F) for 30 minutes. Install the drive gear on the end of camshaft (3). Be sure woodruff key (2) is properly aligned and the drive gear makes contact with the shoulder on the end of the camshaft.End By:a. install camshaft assembly

Typical Example3. Remove thrust pin (1), and remove camshaft assembly (2) from the engine. The following steps are for the installation of the camshaft assembly.4. Be sure the camshaft assembly is thoroughly clean. Put clean engine oil on the lobes and journals of the camshaft assembly. When installing the camshaft, rotating it in both clockwise and counterclockwise directions will help prevent it from binding in the bearing bores.5. Carefully install camshaft assembly (2) in the engine.

Camshaft Timing

When installing the camshaft assembly, be sure the number one cylinder is at (TDC) top dead center of the compression stroke with the timing pin installed in the flywheel. Camshaft timing is very important. The timing mark on the camshaft drive gear must line up with the idler gear timing mark as shown in the illustration. For more information about timing of engine, refer to the "Specifications" module, Form No. SENR5560.

6. With the camshaft properly timed and positioned, install thrust pin (1). Tighten thrust pin (1) to a torque of 48 7 N m (35 5 lb ft). Remove the wires that were used to hold the cam roller followers up off of the camshaft.End By:a. install front housing groupb. install speed/timing sensorc. install vibration damper and pulleyd. install alternatore. install drive belt and belt tightener groupf. install fuel transfer pumpg. install electronic unit injectorsh. install rocker arm assemblies and push rodsDisassemble & Assemble Camshaft Assembly

Start By:a. remove camshaft assembly1. Wrap camshaft portion of camshaft assembly with paper towels to protect the camshaft from being damaged.

Care must be taken not to allow the camshaft to fall to the floor when pressing it from the drive gear. Also, be sure that a camshaft lobe does not catch on the press plates.

2. Place the camshaft assembly in a press. Press camshaft (3) from drive gear (1).3. Remove woodruff key (2) from the camshaft. The following steps are for the assembly of the camshaft and the gear assembly.4. Install woodruff key (2) in the camshaft.5. Heat drive gear (1) to a maximum temperature of 300 C (572 F) for 30 minutes. Install the drive gear on the end of camshaft (3). Be sure woodruff key (2) is properly aligned and the drive gear makes contact with the shoulder on the end of the camshaft.End By:a. install camshaft assembly

Have questions with 107755-0340?

Group cross 107755-0340 ZEXEL

Mitsubishi

Hino

Mitsubishi

107755-0340

F 01G 09P 1H8

ME225190

INJECTOR