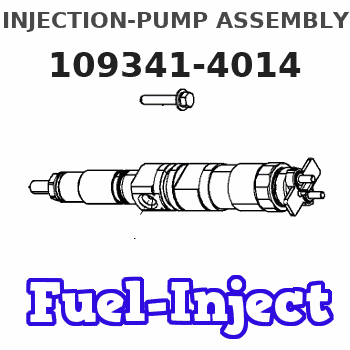

Information injection-pump assembly

BOSCH

9 461 629 122

9461629122

ZEXEL

109341-4014

1093414014

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

MOMOBM Diesel Engine High-pressure Fuel Pump Fuel Pump 0470504029 Compatible for Nissan Diesel Pump,OEM 109341-4014,Fuel Delivery System

MOMOBM OEM NO:109341-4014 || PRECISION PARTS: Direct Replacement OEM High Pressure Fuel Pump || EXTRA LONG LIFE DESIGN: Rigorously Tested-Double Carbon Brushes and Corrosion Resistant Housing to meet factory specifications-No modifications required, eliminating the risk of fuel leakage || Efficient Fuel Delivery System: Reinforced stainless steel pump core + ceramic coated pistons for optimised combustion performance - Enhanced fuel atomisation to reduce engine knock and increase MPG || Plug & Play Installation Includes complete bolt-on kit (gaskets/seals/bolts)

MOMOBM OEM NO:109341-4014 || PRECISION PARTS: Direct Replacement OEM High Pressure Fuel Pump || EXTRA LONG LIFE DESIGN: Rigorously Tested-Double Carbon Brushes and Corrosion Resistant Housing to meet factory specifications-No modifications required, eliminating the risk of fuel leakage || Efficient Fuel Delivery System: Reinforced stainless steel pump core + ceramic coated pistons for optimised combustion performance - Enhanced fuel atomisation to reduce engine knock and increase MPG || Plug & Play Installation Includes complete bolt-on kit (gaskets/seals/bolts)

Suitable Compatible with Nissan Diesel Engine high-Pressure Fuel Pump Fuel Pump Diesel Pump 109341-4014 0470504029

HUIBEIMI Mechanical high pressure fuel pump Steady fuel supply improves ride comfort and response speed || The fuel pump has the advantages of simple structure, convenient maintenance and reduced operating cost || The common rail high pressure fuel pump controls the amount and time of fuel injection to improve combustion efficiency || The high-pressure fuel pump can improve the dynamic performance of the engine, making the vehicle accelerate faster and more powerful || Suitable Compatible with Nissan diesel engine high-pressure fuel pump Fuel pump Diesel pump 109341-4014 0470504029

HUIBEIMI Mechanical high pressure fuel pump Steady fuel supply improves ride comfort and response speed || The fuel pump has the advantages of simple structure, convenient maintenance and reduced operating cost || The common rail high pressure fuel pump controls the amount and time of fuel injection to improve combustion efficiency || The high-pressure fuel pump can improve the dynamic performance of the engine, making the vehicle accelerate faster and more powerful || Suitable Compatible with Nissan diesel engine high-pressure fuel pump Fuel pump Diesel pump 109341-4014 0470504029

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 109341-4014 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 109241-4014 |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105118-8220 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 21.0{214}/39.5{403} |

| 10. | NOZZLE-HOLDER | |

| 11. | NOZZLE |

Scheme ###:

| 3. | [1] | 149351-0201 | PACKING RING |

| 7. | [1] | 149050-0220 | SUPPLY PUMP |

| 9. | [1] | 149055-0000 | SUPPORT RING |

| 10. | [4] | 149330-2000 | TORX SCREW |

| 12. | [1] | 149100-0520 | DRIVE SHAFT |

| 17/1. | [1] | 149110-0000 | SHIM D42.5627.1T2.2 |

| 17/1B. | [1] | 149110-0100 | SHIM D42.5&27.1T2.3 |

| 17/1C. | [1] | 149110-0200 | SHIM D42.5&27.1T2.4 |

| 17/1D. | [1] | 149110-0300 | SHIM D42.5&27.1T2.5 |

| 17/1E. | [1] | 149110-0400 | SHIM D42.5&27.1T2.6 |

| 17/1F. | [1] | 149110-0500 | SHIM D42.5&27.1T2.7 |

| 17/1G. | [1] | 149110-0600 | SHIM D42.5&27.1T2.8 |

| 17/1H. | [1] | 149110-0700 | SHIM D42.5&27.1T2.9 |

| 17/1I. | [1] | 149110-0800 | SHIM D42.5&27.1T3.0 |

| 17/1J. | [1] | 149110-0900 | SHIM D42.5&27.1T3.1 |

| 17/1K. | [1] | 149110-1000 | SHIM D42.5&27.1T3.2 |

| 17B/1. | [1] | 149110-1200 | SHIM D42.5&27.1T2.2 |

| 17B/1B. | [1] | 149110-1300 | SHIM D42.5&27.1T2.3 |

| 17B/1C. | [1] | 149110-1400 | SHIM D42.5&27.1T2.4 |

| 17B/1D. | [1] | 149110-1500 | SHIM D42.5&27.1T2.5 |

| 17B/1E. | [1] | 149110-1600 | SHIM D42.5&27.1T2.6 |

| 17B/1F. | [1] | 149110-1700 | SHIM D42.5&27.1T2.7 |

| 17B/1G. | [1] | 149110-1800 | SHIM D42.5&27.1T2.8 |

| 17B/1H. | [1] | 149110-1900 | SHIM D42.5&27.1T2.9 |

| 17B/1I. | [1] | 149110-2000 | SHIM D42.5&27.1T3.0 |

| 17B/1J. | [1] | 149110-2100 | SHIM D42.5&27.1T3.1 |

| 17B/1K. | [1] | 149110-2200 | SHIM D42.5&27.1T3.2 |

| 19. | [1] | 149111-0000 | DRIVER DISC |

| 20. | [1] | 149120-0020 | CAM RING |

| 21. | [2] | 149112-0200 | ROLLER SHOE |

| 22. | [2] | 149113-0300 | ROLLER |

| 23. | [1] | 149111-0100 | PLATE |

| 25. | [1] | 149114-0000 | BEARING PLATE |

| 30. | [1] | 149350-3300 | O-RING |

| 35. | [1] | 149170-0022 | HYDRAULIC STOPPER |

| 36. | [1] | 149350-3400 | O-RING |

| 37. | [1] | 149180-0101 | CLOSING COVER |

| 38. | [2] | 149330-1800 | TORX BOLT |

| 39. | [1] | 149350-1700 | SEAL RING |

| 42. | [1] | 149164-0000 | COILED SPRING |

| 49. | [4] | 149330-1900 | TORX BOLT |

| 50. | [1] | 149200-1021 | HYDRAULIC HEAD |

| 51. | [3] | 149350-2000 | O-RING |

| 54. | [4] | 149313-2700 | GASKET |

| 58. | [4] | 149300-0023 | PRESSURE-CONTROL VALVE |

| 61. | [3] | 149330-2300 | TORX BOLT |

| 62. | [1] | 149436-0000 | PLATE |

| 63. | [1] | 149350-1900 | O-RING |

| 104. | [2] | 149330-2400 | HEX-SOCKET-HEAD CAP SCREW |

| 104. | [2] | 149330-2400 | HEX-SOCKET-HEAD CAP SCREW |

| 105. | [2] | 149443-0200 | GASKET |

| 105. | [2] | 149443-0200 | GASKET |

| 107. | [1] | 149403-0320 | SENSOR |

| 109. | [3] | 149330-1600 | TORX BOLT |

| 111. | [2] | 149330-0501 | TORX SCREW |

| 123. | [5] | 149330-1700 | TORX BOLT |

| 127. | [1] | 149350-2800 | SEAL RING |

| 133. | [1] | 149350-3500 | O-RING |

| 134. | [1] | 149350-3600 | O-RING |

| 135. | [1] | 149060-0020 | CONTROL VALVE |

| 206. | [1] | 149330-2500 | UNION NUT |

| 207. | [1] | 149412-0000 | PLAIN WASHER |

| 243. | [1] | 149330-2400 | HEX-SOCKET-HEAD CAP SCREW |

| 244. | [1] | 149443-0200 | GASKET |

| 270. | [1] | 149411-2600 | COUPLING PLATE |

| 271/1. | [1] | 149411-1300 | SHIM T0.5 |

| 271/1B. | [1] | 149411-1400 | SHIM T0.6 |

| 271/1C. | [1] | 149411-1500 | SHIM T0.7 |

| 271/1D. | [1] | 149411-1600 | SHIM T0.8 |

| 271/1E. | [1] | 149411-1700 | SHIM T0.9 |

| 271/1F. | [1] | 149411-1800 | SHIM T1.0 |

| 271/1G. | [1] | 149411-1900 | SHIM T1.1 |

| 271/1H. | [1] | 149411-2000 | SHIM T1.2 |

| 271/1I. | [1] | 149411-2100 | SHIM T1.3 |

| 271/1J. | [1] | 149411-2200 | SHIM T1.4 |

| 271/1K. | [1] | 149411-2300 | SHIM T1.5 |

| 271B/1. | [1] | 149411-4000 | SHIM T0.5 |

| 271B/1B. | [1] | 149411-4100 | SHIM T0.6 |

| 271B/1C. | [1] | 149411-4200 | SHIM T0.7 |

| 271B/1D. | [1] | 149411-4300 | SHIM T0.8 |

| 271B/1E. | [1] | 149411-4400 | SHIM T0.9 |

| 271B/1F. | [1] | 149411-4500 | SHIM T1.0 |

| 271B/1G. | [1] | 149411-4600 | SHIM T1.1 |

| 271B/1H. | [1] | 149411-4700 | SHIM T1.2 |

| 271B/1I. | [1] | 149411-4800 | SHIM T1.3 |

| 271B/1J. | [1] | 149411-4900 | SHIM T1.4 |

| 271B/1K. | [1] | 149411-5000 | SHIM T1.5 |

| 392. | [1] | 149350-3700 | O-RING |

| 393. | [1] | 149419-0100 | BLEEDER SCREW |

| 394. | [1] | 149420-0000 | INTERMEDIATE PLATE |

| 394B. | [1] | 149420-0100 | INTERMEDIATE PLATE |

| 400. | [1] | 149460-1300 | CABLE CRAMP |

| 425. | [2] | 149330-2200 | TORX BOLT |

| 471. | [1] | 149410-0000 | COVER |

| 480. | [1] | 149350-3800 | SEAL RING |

| 800S. | [1] | 149480-0620 | SERVICE PARTS GROUP |

| 801S. | [1] | 149481-0320 | PARTS SET |

| 804S. | [1] | 149483-0020 | PARTS SET |

| 804S/14. | [1] | 149350-1800 | O-RING |

| 804S/15. | [1] | 149350-1900 | O-RING |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 805S. | [1] | 149482-0020 | PARTS SET |

| 902. | [1] | 149433-0220 | OUTLET PIPE ASSY |

| 902/1. | [1] | 149070-0120 | OVER FLOW VALVE |

| 902/2. | [1] | 146669-4420 | INLET UNION |

| 902/3. | [2] | 149350-2700 | FLAT SEAL RING |

| 903. | [1] | 149428-0520 | INLET PIPE |

| 903/1. | [1] | 149330-0000 | EYE BOLT |

| 903/2. | [1] | 149425-0020 | INLET UNION |

| 903/3. | [2] | 149350-2600 | FLAT SEAL RING |

Include in #2:

109341-4014

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Bolts And Bolt Torque

A bolt which is too long may "bottom" before the head is tight against the part it is to hold. The threads can be damaged when a "long" bolt is removed.If a bolt is too short, there may not be enough threads engaged to hold the part securely.Apply proper torque values to all bolts and nuts when assembling Caterpillar equipment. When a specific torque value is required, the value is listed in the SPECIFICATIONS section of the Service Manual. Tighten all other bolts and nuts for general usage, hydraulic valve bodies, or taperlock studs to the torque values given in the torque charts.T-T-T Procedure

A torque-turn-tighten (T-T-T) procedure is used in many specifications and instructions. 1. Clean the bolt and nut threads.2. Put lubricant on the threads and the seat face of the bolt and the nut.3. Turn the bolt or the nut tight according to the torque specification.4. Put a location mark on the part and on the bolt or the nut.5. Turn the bolt or the nut tighter the amount of degrees according to the specifications. The side of a nut or bolt head can be used for reference if a mark can not be put on. Torque Wrench Extension

When a torque wrench extension is used with a torque wrench, the torque indication on the torque wrench will be less than the real torque.

TORQUE WRENCH WITH TORQUE WRENCH EXTENSION

E: Torque wrench drive axis-to-torque wrench extension drive axis. W: Mark on handle-to-torque wrench drive axis.1. Put a mark on the handle. Measure the handle from the mark to the axis of the torque wrench drive (W).2. Measure the torque wrench extension from the torque wrench drive to the axis of the torque wrench extension drive (E).3. To get correct torque indication (TI) when the real torque (RT) is known: Example: W = 12 in. (304.8 mm); E = 2.56 in. (65.0 mm); RT (from specifications) = 125 lb. ft. (170 N m). 4. Hold the torque wrench handle with the longest finger of the hand over the mark on the handle to get the real torque (RT) with low torque indication (TI) on the torque wrench.Locks

Flat metal locks must be installed properly to be effective. Bend one end of the lock around the edge of the part. Bend the other end against one flat surface of the nut or bolt head.Always install new locks in compartments which house moving parts.If lockwashers are installed on housings made of aluminum, use a flat washer between the lockwasher and the housing. Lines And Wires

When removing or disconnecting a group of lines or wires, tag each one to assure proper assembly.Lubrication

Where applicable, fill the compartments of the components serviced with the amount, type and grade of lubricant recommended in the Lubrication and Maintenance Guide.Rust Preventive Compound

Clean the rust preventive compound from all machined surfaces of new parts before installing them.Shims

When shims are removed, tie them together and identify them as to location. Keep shims clean and flat until they

A bolt which is too long may "bottom" before the head is tight against the part it is to hold. The threads can be damaged when a "long" bolt is removed.If a bolt is too short, there may not be enough threads engaged to hold the part securely.Apply proper torque values to all bolts and nuts when assembling Caterpillar equipment. When a specific torque value is required, the value is listed in the SPECIFICATIONS section of the Service Manual. Tighten all other bolts and nuts for general usage, hydraulic valve bodies, or taperlock studs to the torque values given in the torque charts.T-T-T Procedure

A torque-turn-tighten (T-T-T) procedure is used in many specifications and instructions. 1. Clean the bolt and nut threads.2. Put lubricant on the threads and the seat face of the bolt and the nut.3. Turn the bolt or the nut tight according to the torque specification.4. Put a location mark on the part and on the bolt or the nut.5. Turn the bolt or the nut tighter the amount of degrees according to the specifications. The side of a nut or bolt head can be used for reference if a mark can not be put on. Torque Wrench Extension

When a torque wrench extension is used with a torque wrench, the torque indication on the torque wrench will be less than the real torque.

TORQUE WRENCH WITH TORQUE WRENCH EXTENSION

E: Torque wrench drive axis-to-torque wrench extension drive axis. W: Mark on handle-to-torque wrench drive axis.1. Put a mark on the handle. Measure the handle from the mark to the axis of the torque wrench drive (W).2. Measure the torque wrench extension from the torque wrench drive to the axis of the torque wrench extension drive (E).3. To get correct torque indication (TI) when the real torque (RT) is known: Example: W = 12 in. (304.8 mm); E = 2.56 in. (65.0 mm); RT (from specifications) = 125 lb. ft. (170 N m). 4. Hold the torque wrench handle with the longest finger of the hand over the mark on the handle to get the real torque (RT) with low torque indication (TI) on the torque wrench.Locks

Flat metal locks must be installed properly to be effective. Bend one end of the lock around the edge of the part. Bend the other end against one flat surface of the nut or bolt head.Always install new locks in compartments which house moving parts.If lockwashers are installed on housings made of aluminum, use a flat washer between the lockwasher and the housing. Lines And Wires

When removing or disconnecting a group of lines or wires, tag each one to assure proper assembly.Lubrication

Where applicable, fill the compartments of the components serviced with the amount, type and grade of lubricant recommended in the Lubrication and Maintenance Guide.Rust Preventive Compound

Clean the rust preventive compound from all machined surfaces of new parts before installing them.Shims

When shims are removed, tie them together and identify them as to location. Keep shims clean and flat until they