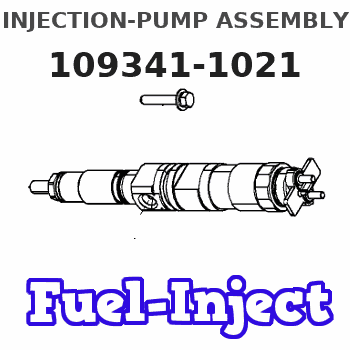

Information injection-pump assembly

ZEXEL

109341-1021

1093411021

ISUZU

8973267390

8973267390

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

VP44 Fuel Injection Pump Compatible with Isuzu D-Max 4JH1 3.0L Engine 109341-1024 0470504048 8973267390 8-97326-739-0

EWAIDI Part Number: 0470504048 109341-1024 8973267390 8-97326-739-0 || Engine Model: for Isuzu D-Max 4JH1 3.0L Engine || The VP44 Diesel Fuel Distributor Injection Pump is a vital component in diesel vehicles, delivering fuel to injectors for optimal engine performance. Known for reliability and durability, regular maintenance is essential to prevent issues. This high-pressure pump plays a key role in combustion, ensuring fuel efficiency and smooth engine operation. || for verification. It is important to ensure compatibility and avoid any potential issues with your purchase. Thank you for your attention to detail and cooperation. || Service: We offer a generous 5-month warranty on all our products, along with round-the-clock customer support. If you have any questions or concerns, please don't hesitate to reach out to us via email.

EWAIDI Part Number: 0470504048 109341-1024 8973267390 8-97326-739-0 || Engine Model: for Isuzu D-Max 4JH1 3.0L Engine || The VP44 Diesel Fuel Distributor Injection Pump is a vital component in diesel vehicles, delivering fuel to injectors for optimal engine performance. Known for reliability and durability, regular maintenance is essential to prevent issues. This high-pressure pump plays a key role in combustion, ensuring fuel efficiency and smooth engine operation. || for verification. It is important to ensure compatibility and avoid any potential issues with your purchase. Thank you for your attention to detail and cooperation. || Service: We offer a generous 5-month warranty on all our products, along with round-the-clock customer support. If you have any questions or concerns, please don't hesitate to reach out to us via email.

VP44 Fuel Injection Pump 8-97326739-0 8-97326739-3 8973267393 0470504037 0470504048 8-973267390 ZEXEL 109341-1024 Compatible for ISUZU 4JH1 D-Max

Fikowjs TIP: Please purchase according to the old part number, appearance is not able to judge the accuracy of the product. || Product Name:Fuel Injection Pump || Product Number:8-97326739-0 8-97326739-3 8973267393 0470504037 0470504048 8-973267390 || Application: Compatible for ISUZU 4JH1 D-Max || NOTE: There are many kinds of products in Fikowjs parts, if you can't find the part number you need, please consult us, we will reply soon!

Fikowjs TIP: Please purchase according to the old part number, appearance is not able to judge the accuracy of the product. || Product Name:Fuel Injection Pump || Product Number:8-97326739-0 8-97326739-3 8973267393 0470504037 0470504048 8-973267390 || Application: Compatible for ISUZU 4JH1 D-Max || NOTE: There are many kinds of products in Fikowjs parts, if you can't find the part number you need, please consult us, we will reply soon!

IMELBUFF 0470504037 0470504048 109341-1024 8973267393 8973267390 VP44 Fuel Injection Pump for Isuzu Rodeo 4JH1 4KH1 D-Max 3.0L Diesel Engine

IMELBUFF 🚜Part Number: 0470504037 0470504048 8-97326-739-0 8973267390 8-97326-739-3, 8973267393 109341-1024 || 🚜Engine Model: for Holden Rodeo & Isuzu D-Max 4JH1 4KH1 3.0 DiTD 120 Kw || 🚜Part Type: VP44 Fuel Distributor Injection Pump || 🚜Warm Tips: If you are not sure that the pump is suitable for your vehicle, please send us email with your vehicle engine model and fuel pump part number || 🚜Service: 6-months-warranty and 24 hour support for customer service. Please feel free to contact us by email if you have any question with the product

IMELBUFF 🚜Part Number: 0470504037 0470504048 8-97326-739-0 8973267390 8-97326-739-3, 8973267393 109341-1024 || 🚜Engine Model: for Holden Rodeo & Isuzu D-Max 4JH1 4KH1 3.0 DiTD 120 Kw || 🚜Part Type: VP44 Fuel Distributor Injection Pump || 🚜Warm Tips: If you are not sure that the pump is suitable for your vehicle, please send us email with your vehicle engine model and fuel pump part number || 🚜Service: 6-months-warranty and 24 hour support for customer service. Please feel free to contact us by email if you have any question with the product

You can express buy:

USD 940.88

31-05-2025

31-05-2025

8973267391 8-97326739-0 Fuel Injection Pump for ISUZU 4JH1 D-Max 8-97326739-3 8973267393 0470504037 0470504048 109341-1024

USD 899.2

28-05-2025

28-05-2025

8973267391 Fuel Injection Pump for ISUZU 4JH1 D-Max 8-97326739-0 8-97326739-3 8973267393 0470504037 0470504048 109341-1024

Images:

USD 700

[13-May-2025]

USD 328.62

[14-Jun-2025]

USD 1082.8

[19-May-2025]

USD 1109.86

[19-May-2025]

Components :

| 0. | INJECTION-PUMP ASSEMBLY | 109341-1021 |

| 1. | _ | |

| 2. | FUEL INJECTION PUMP | 109241-1003 |

| 3. | NUMBER PLATE | |

| 4. | _ | |

| 5. | CAPSULE | |

| 6. | ADJUSTING DEVICE | |

| 7. | NOZZLE AND HOLDER ASSY | 105118-8212 |

| 8. | Nozzle and Holder | |

| 9. | Open Pre:MPa(Kqf/cm2) | 19.5{199}/33.8{345} |

| 10. | NOZZLE-HOLDER | 105048-2270 |

| 11. | NOZZLE | 105017-3090 |

Include in #2:

109341-1021

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

start by:a) remove vibration damper and pulley

The crankshaft front seal and wear sleeve come as a set and must be installed as a set. If a replacement of the seal is to be made, a replacement of the wear sleeve must also be made.

1. Make at least three holes in seal (1) with a hammer and a sharp punch. 2. Use tool (A) to remove seal (1). 3. Install tool (C) into the seal bore.4. Install tool (B) between tool (C) and the wear sleeve. Turn tool (B) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.5. Remove tool (C) and the wear sleeve by hand.Install Crankshaft Front Seal And Wear Sleeve

The crankshaft seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, Form No. SMHS8508, that is included with each seal and wear sleeve before any handling of the seal group is made.

1. Install the front crankshaft seal and wear sleeve with tooling (A). Use the procedures which follow: a. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 6V1541 Quick Cure Primer. Make an application of 9S3265 Retaining Compound to the crankshaft outside diameter before the wear sleeve is installed on the crankshaft. Do not let any Quick Cure Primer or Retaining Compound get on the lip of the seal.

TYPICAL EXAMPLEb. Install locator (3) and bolts (4) on the crankshaft.c. Seal (1) and wear sleeve (2) must be installed dry.

Make sure the seal is installed with the part number and the arrows showing crankshaft rotation toward the outside.

The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving the oil back into the engine.

d. Put wear sleeve (2) and seal (1) as a unit in position on locator (3).e. Put installer (5) in position on locator (3).f. Put clean engine oil on the face of nut (6) and its contact area on installer (5). Install nut (6) on locator (3).g. Tighten nut (6) until the inside surface of installer (5) comes in contact with locator (3).h. Remove tooling (A) from the crankshaft seal and wear sleeve. Tooling (A) will install the seal and wear sleeve to the correct depth on the crankshaft.end by:a) install vibration damper and pulley

The crankshaft front seal and wear sleeve come as a set and must be installed as a set. If a replacement of the seal is to be made, a replacement of the wear sleeve must also be made.

1. Make at least three holes in seal (1) with a hammer and a sharp punch. 2. Use tool (A) to remove seal (1). 3. Install tool (C) into the seal bore.4. Install tool (B) between tool (C) and the wear sleeve. Turn tool (B) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.5. Remove tool (C) and the wear sleeve by hand.Install Crankshaft Front Seal And Wear Sleeve

The crankshaft seal and wear sleeve come as a set and must not be separated from each other at any time. Carefully read Special Instruction, Form No. SMHS8508, that is included with each seal and wear sleeve before any handling of the seal group is made.

1. Install the front crankshaft seal and wear sleeve with tooling (A). Use the procedures which follow: a. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 6V1541 Quick Cure Primer. Make an application of 9S3265 Retaining Compound to the crankshaft outside diameter before the wear sleeve is installed on the crankshaft. Do not let any Quick Cure Primer or Retaining Compound get on the lip of the seal.

TYPICAL EXAMPLEb. Install locator (3) and bolts (4) on the crankshaft.c. Seal (1) and wear sleeve (2) must be installed dry.

Make sure the seal is installed with the part number and the arrows showing crankshaft rotation toward the outside.

The front and rear seals and wear sleeves have different spiral grooves in the seal. Because of this type of design, the front seal group for an engine is different from the rear seal group. If a seal group is installed on the wrong end of the engine, oil can actually be taken out of the engine instead of moving the oil back into the engine.

d. Put wear sleeve (2) and seal (1) as a unit in position on locator (3).e. Put installer (5) in position on locator (3).f. Put clean engine oil on the face of nut (6) and its contact area on installer (5). Install nut (6) on locator (3).g. Tighten nut (6) until the inside surface of installer (5) comes in contact with locator (3).h. Remove tooling (A) from the crankshaft seal and wear sleeve. Tooling (A) will install the seal and wear sleeve to the correct depth on the crankshaft.end by:a) install vibration damper and pulley