Information injection-pump assembly

ZEXEL

108922-2070

1089222070

Rating:

Cross reference number

ZEXEL

108922-2070

1089222070

Zexel num

Bosch num

Firm num

Name

108922-2070

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

52

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-8-

5-6-3-4-

9-10

Pre-stroke

mm

8.5

8.47

8.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.75 45.25

Cyl.1-2 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-8 deg. 117 116.75 117.25

Cal 1-8 deg. 117 116.75 117.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-6 deg. 189 188.75 189.25

Cal 1-6 deg. 189 188.75 189.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-4 deg. 261 260.75 261.25

Cal 1-4 deg. 261 260.75 261.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cal 1-10 deg. 333 332.75 333.25

Cal 1-10 deg. 333 332.75 333.25

Injection quantity adjustment

Rack position

(11.2)

Vist

V

1.75

1.75

1.75

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

134

133

135

Max. variation between cylinders

%

0

-3

3

Basic

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

Injection quantity adjustment_02

Rack position

(6.8)

Vist

V

2.6

2.5

2.7

Pump speed

r/min

330

330

330

Average injection quantity

mm3/st.

19

17

21

Max. variation between cylinders

%

0

-15

15

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

8.4+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

0000001201

Pre-stroke

mm

8.5

8.47

8.53

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

8.5

8

9

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.1

6.05

6.15

Output voltage

V

2.45

2.44

2.46

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

8.5

8.47

8.53

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.5

Output voltage

V

3

2.98

3

Confirmation

*

_06

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

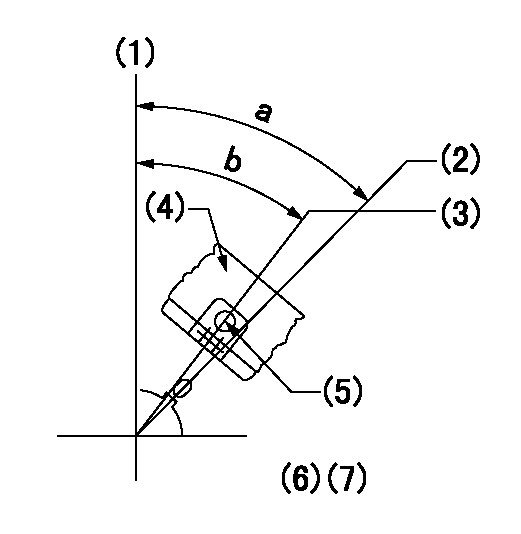

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=16mm bb=1mm

----------

a=19deg+-5deg b=29deg+-5deg

----------

aa=16mm bb=1mm

----------

a=19deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)At the No 1 cylinder's beginning of injection position, stamp an aligning mark on the damper to align with the pointer's groove.

(4)Damper

(5)Pointer

(6)B.T.D.C.: aa

(7)Pre-stroke: bb

----------

aa=6deg bb=8.5+-0.03mm

----------

a=(45deg) b=(44deg)

----------

aa=6deg bb=8.5+-0.03mm

----------

a=(45deg) b=(44deg)

0000001501

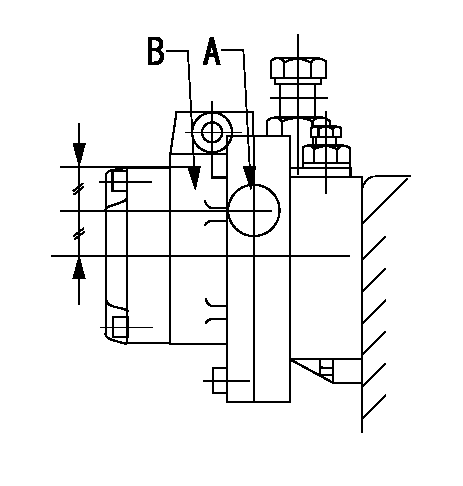

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000001701

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

0000001901 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (154610-0620)

(1)At governor side rack sensor output voltage V1, adjust the bobbin (A) so that the drive side rack sensor output voltage is VR+-0.01.

(2)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

V1=1V

----------

----------

V1=1V

----------

Information:

PROBLEM

The fuel inlet check valves, on the fuel injection pump, may fail on certain C6.6 Industrial Engines that are installed in specific OEM Applications. A failure of the inlet check valves could result in any of the following symptoms: failure to start, prevention of the engine from achieving full power, or a de-rate of the engine.

Before any repair is carried out, ensure the appropriate trouble shooting steps have been followed and carried out.

AFFECTED PRODUCT

Model Identification Number

C6.6 TIER 3 66605372, 5675-5678, 5680-5683, 5685-5686, 5688-5695, 5697-5699, 5701-5703, 5718, 5720, 5722-5723, 5726, 5728-5729, 5733, 5735-5737, 5739, 5741-5749, 5751-5754, 5756, 5758-5771, 6007-6008, 6010, 6012-6013, 6015, 6018, 6020-6021, 6024, 6438, 7207-7209, 7211-7215, 7222-7225, 7227-7231, 7235, 7237-7239, 7268-7271, 7273-7275, 7277, 7280-7281, 7284-7287, 7428, 9732, 9747, 9749-9751, 9753-9754, 9756-9760, 9765, 9790-9791, 9794-9800, 9804-9807, 9809, 9823-9826, 9828, 9830-9837, 9839, 9842, 9877, 9879-9884, 9886-9891, 9893-9894, 9897-9898, 9901-9902, 9931, 9933-9937, 9940-9943, 9945, 9947, 9950, 9952-9954, 9959-9960, 10000, 10003, 10005, 10009-10010, 10012-10013, 10015-10016, 10018-10023, 10116, 10119-10125, 10129, 10131-10133, 10135-10136, 10138-10141, 10144-10145, 10147-10149

PARTS NEEDED

Qty

Part Number Description

1 1113423 WASHER

1 2258019 GASKET-PUMP-HSG

6 2323149 WASHER-SEALING

1 2782285 ELBOW

1 2784138 PROTECTION KT

1 3368180 TUBE FUEL-INJ

1 3495736 PUMP GP-FUEL

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 1% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Replace the existing fuel injection pump group with a new 349-5736 fuel injection pump group.

Refer to appropriate service manuals as necessary.

Rework Procedure:

1. Remove machine parts as necessary to gain sufficient access to the engine.

2. Remove existing fuel injection pump and replace it with a new 349-5736 fuel injection pump group. Refer to the Disassembly & Assembly Instruction RENR9722 Fuel Injection Pump - Remove and Install. If a compression fitting is used to connect the pipe from the filter to the pump a new nut and olive will be required. This is part of the elbow assembly 278-2285, remove one of the nuts and olives from the elbow and use this to reconnect the pipe to the new pump, the rest of the elbow can be discarded.

3. Ensure that all the warnings and notices are adhered to and safety practices are followed. Ensure that the protection caps are used during this operation to prevent issues with contamination.

4. Install all parts that were removed to gain access to the engine.

5. Check for leaks and repair as necessary.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-3000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 8.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 108922-2070?

Group cross 108922-2070 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

108922-2070

INJECTION-PUMP ASSEMBLY