Information injection-pump assembly

BOSCH

9 400 611 305

9400611305

ZEXEL

108922-1080

1089221080

Rating:

Service parts 108922-1080 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

11.

Nozzle and Holder

1-15300-345-0

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.1{225}

14.

NOZZLE

Include in #1:

108922-1080

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 611 305

9400611305

ZEXEL

108922-1080

1089221080

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED4 control unit part number

407915-0

590

RED4 rack sensor specifications

mm

19

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

51

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

7.2

7.17

7.23

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 32 31.75 32.25

Cal 1-8 deg. 32 31.75 32.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 104 103.75 104.25

Cal 1-6 deg. 104 103.75 104.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 176 175.75 176.25

Cal 1-4 deg. 176 175.75 176.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 248 247.75 248.25

Cal 1-10 deg. 248 247.75 248.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 320 319.75 320.25

Cyl.1-2 deg. 320 319.75 320.25

Injection quantity adjustment

Rack position

(12.2)

PWM

%

57

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

158.5

156.5

160.5

Max. variation between cylinders

%

0

-3

3

Basic

*

PS407980-224*

V

2.2+-0.0

1

PS407980-224*

mm

4.8+-0.0

5

Injection quantity adjustment_02

Rack position

(6.5)

PWM

%

24.7+-2.

8

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

16.5

13.3

19.7

Max. variation between cylinders

%

0

-13

13

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

7.1+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

0000001201

Pre-stroke

mm

7.2

7.17

7.23

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

11.5

11

12

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

3.2

3.15

3.25

Output voltage

V

2.95

2.94

2.96

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

7.2

7.17

7.23

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

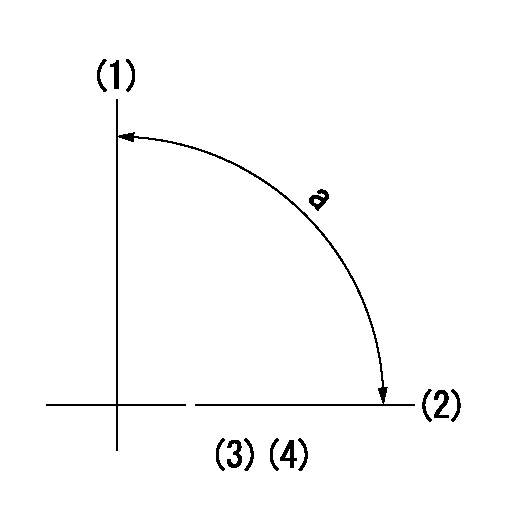

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=37deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=37deg+-5deg b=37deg+-5deg

0000000901

(1)Pump vertical direction

(2)Position of coupling's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=1deg bb=7.2+-0.03mm

----------

a=(90deg)

----------

aa=1deg bb=7.2+-0.03mm

----------

a=(90deg)

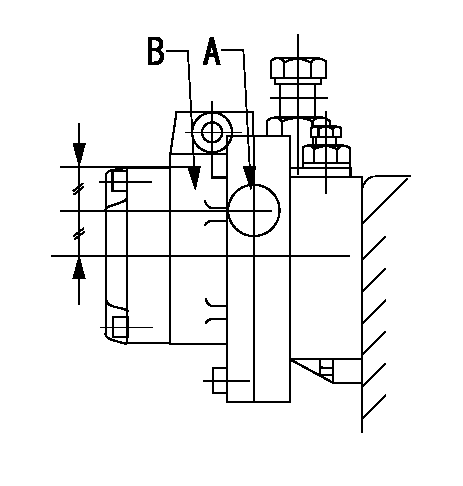

0000001501

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000001701

(PWM) Pulse width modulation (%)

(R) Rack position (mm)

Rack sensor output characteristics

1. Rack limit adjustment

(1)Measure the rack position R2 for PWM a2%.

(2)Confirm that it is within the range R2 = 15+-1 mm.

(3)Measure the rack position R1 at PWM a %.

(4)Confirm that it is within the range R2 - R1 = 10+-0.1 mm.

2. Check the limp home operation.

(1)Move the switch box's limp home switch to the limp home side.

(2)Confirm rack position L1 (mm ) and L2 (mm) for PWM in the above table.

3. Check the pull down operation.

(1)Confirm that the rack position is 19 mm at PWM B%.

(2)In the conditions described in the above table, move the switch box's pull down switch to the pull down side and confirm that the rack position momentarily becomes 1 mm or less.

----------

a1=16.25 % a2=72.5 % L1=1-- mm L2=19++mm A=5 % B=95 %

----------

----------

a1=16.25 % a2=72.5 % L1=1-- mm L2=19++mm A=5 % B=95 %

----------

Information:

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

28Feb2007 31Aug2007

PROBLEM

The torque on the 100-6920 Direct Injection Fuel Nozzle Adapters may be out of specification.

AFFECTED PRODUCT

Model Identification Number

3408C TAM00350-00351

3412 38S24043

BCS02130

3412C 9BR03238

9EP03871, 3969-3970, 3972-3973

DJN01044-01070, 1074-1076, 1081, 1087

RLR00339, 341-342

TFT00565-00583

PARTS NEEDED

No parts needed for this program

ACTION REQUIRED

Remove valve covers, fuel lines and fuel nozzles. Tighten the 100-6920 Direct Injection Fuel Nozzle Adapters to 200 +/- 14 Nm (150 +/- 10 lb ft). Reassemble engine. For detailed instructions, refer to the procedure in the Disassembly and Assembly manual. Test engine for proper operation after reassembly.

OWNER NOTIFICATION

U.S. and Canadian owners will receive the attached Owner Notification.

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 3.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

COPY OF OWNER NOTIFICATION FOR U.S. AND CANADIAN OWNERS

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR TIGHTENING THE DIRECT INJECTION FUEL NOZZLE ADAPTERS

MODELS INVOLVED - Certain 3408 and 3412 Engines

Dear Caterpillar Product Owner:

The torque on the Direct Injection Fuel Nozzle Adapters may be out of specification. The Direct Injection Fuel Nozzle Adapters need to be tightened to the correct torque on the products listed below. You will not be charged for the service performed.

Contact your local Caterpillar dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

Please refer the dealer to their Service Letter dated 24Aug2006 when scheduling this service.

We regret the inconvenience this may cause you, but urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 24Aug2006 Service Letter