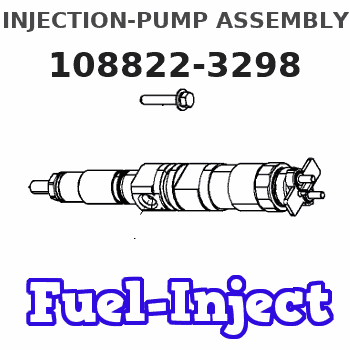

Information injection-pump assembly

BOSCH

9 400 612 326

9400612326

ZEXEL

108822-3298

1088223298

HINO

220401754A

220401754a

Rating:

Service parts 108822-3298 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

11.

Nozzle and Holder

23600-3342A

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

14.

NOZZLE

Include in #1:

108822-3298

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

108822-3298

9 400 612 326

220401754A HINO

INJECTION-PUMP ASSEMBLY

F21C-D K 14CQ INJECTION PUMP ASSY TICS HD-TI8F TICS

F21C-D K 14CQ INJECTION PUMP ASSY TICS HD-TI8F TICS

Information:

Do not use the same vacuum sampling pump for extracting oil samples that is used for extracting coolant samples.A small residue of either type sample may remain in the pump and may cause a false positive analysis for the sample being taken.Always use a separate pump for oil sampling and a separate pump for coolant sampling.Failure to do so may cause a false analysis which could lead to customer and dealer concerns.

New Systems, Refilled Systems, and Converted Systems

Perform an S O S coolant analysis (Level 2) at the following maintenance intervals.

Initial 500 service hours

Every Year or every 2000 hours, whichever comes firstPerform this analysis at the interval that occurs first for new systems, for refilled systems, or for converted systems that use Cat ELC (Extended Life Coolant) or use Cat DEAC (Diesel Engine Antifreeze/Coolant). This 500 hour check will also check for any residual cleaner that may have contaminated the system.Recommended Interval for S O S Services Coolant Sample

The following table contains the recommended sampling interval for all coolants that meet Cat EC-1 (Engine Coolant specification - 1). This is also the recommended sampling interval for all conventional heavy-duty coolant/antifreeze.The Level 2 Coolant Analysis should be performed if a problem is suspected or identified.

Table 1

Recommended Interval

Type of Coolant Level 1 Level 2

Cat DEAC

and Conventional Heavy-Duty Coolants Every 250 hours Yearly

Cat ELC

and Commercial EC-1 coolants Optional or every 500 hours Yearly or every 500 hours Note: Check the SCA (Supplemental Coolant Additive) of the conventional coolant at every oil change or at every 250 hours. Perform this check at the interval that occurs first.Refer to your machine OMM for recommendations specific to your machine.S O S Services Coolant Analysis (Level 1)

A coolant analysis (Level 1) is a test of the properties of the coolant.The following properties of the coolant are tested:

Glycol concentration for freeze protection and boil protection

Ability to protect from erosion and corrosion

pH

Conductivity

Visual analysis

Odor analysisThe results are reported, and appropriate recommendations are made.S O S Services Coolant Analysis (Level 2)

A coolant analysis ( Level 2) is a comprehensive chemical evaluation of the coolant. This analysis is also a check of the overall condition of the cooling system.The S O S coolant analysis ( Level 2) has the following features:

Full coolant analysis (Level 1)

Identification of metal corrosion and of contaminants

Identification of buildup of the impurities that cause corrosion

Identification of buildup of the impurities that cause scaling

Determination of the possibility of electrolysis within the cooling system of the engineThe results are reported, and appropriate recommendations are made.For more information on S O S coolant analysis, consult your Caterpillar dealer.

Have questions with 108822-3298?

Group cross 108822-3298 ZEXEL

Hino

Hino

108822-3298

9 400 612 326

220401754A

INJECTION-PUMP ASSEMBLY

F21C-D

F21C-D