Information injection-pump assembly

ZEXEL

108822-2720

1088222720

Rating:

Cross reference number

ZEXEL

108822-2720

1088222720

Zexel num

Bosch num

Firm num

Name

108822-2720

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

42

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-2-7-3-

4-5-6-8

Pre-stroke

mm

8.5

8.47

8.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cyl.1-2 deg. 45 44.75 45.25

Cyl.1-2 deg. 45 44.75 45.25

Difference between angles 2

Cal 1-7 deg. 90 89.75 90.25

Cal 1-7 deg. 90 89.75 90.25

Difference between angles 3

Cal 1-3 deg. 135 134.75 135.25

Cal 1-3 deg. 135 134.75 135.25

Difference between angles 4

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 5

Cal 1-5 deg. 225 224.75 225.25

Cal 1-5 deg. 225 224.75 225.25

Difference between angles 6

Cal 1-6 deg. 270 269.75 270.25

Cal 1-6 deg. 270 269.75 270.25

Difference between angles 7

Cal 1-8 deg. 315 314.75 315.25

Cal 1-8 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

-

Rack position

13.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

136.5

134.9

138.1

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.7+-0.5

Pump speed

r/min

345

345

345

Average injection quantity

mm3/st.

23.5

20.9

26.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

8.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.3)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

136.5

135.5

137.5

Basic

*

Fixing the lever

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

137

133

141

Fixing the lever

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R1-0.7)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

132.5

128.5

136.5

Fixing the lever

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

0000001601

Pre-stroke

mm

8.5

8.47

8.53

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

8.5

8

9

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.1

6.05

6.15

Output voltage

V

2.45

2.44

2.46

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

8.5

8.47

8.53

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.5

Output voltage

V

3

2.98

3

Confirmation

*

_06

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

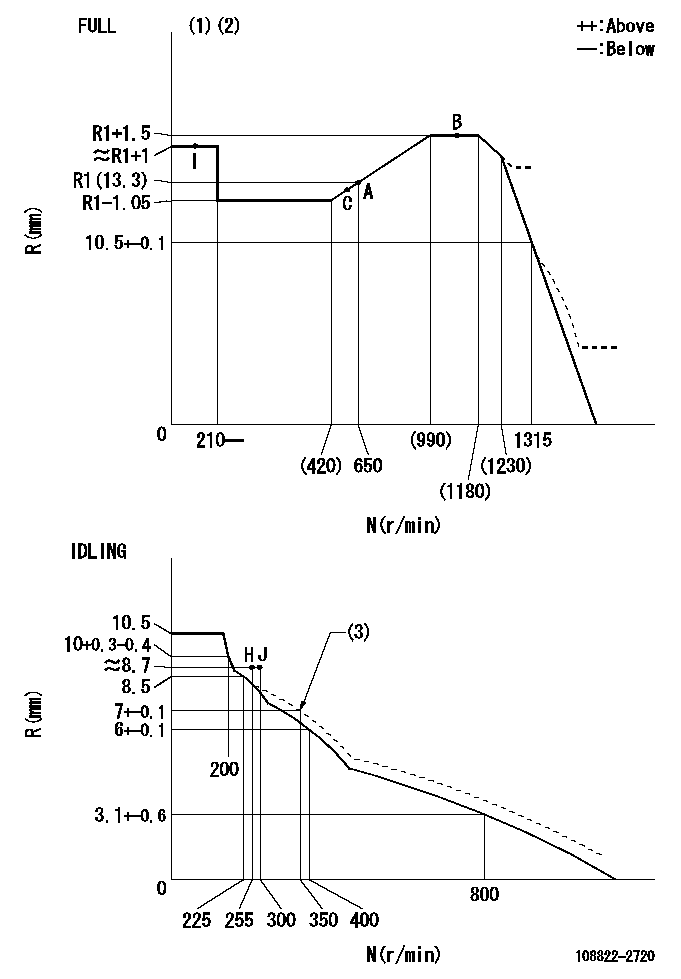

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AC49

----------

----------

T1=AC49

----------

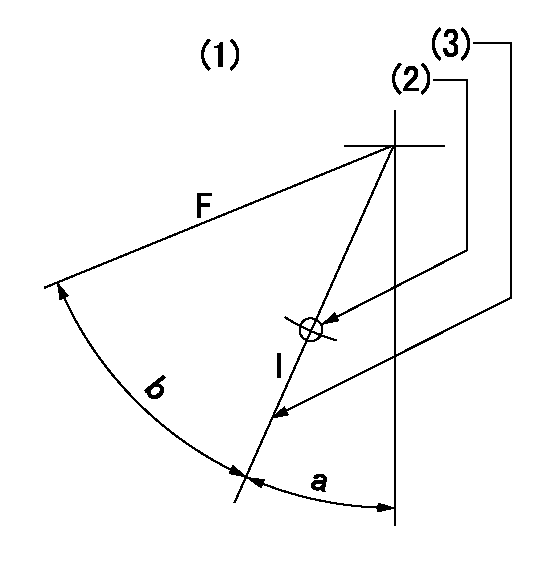

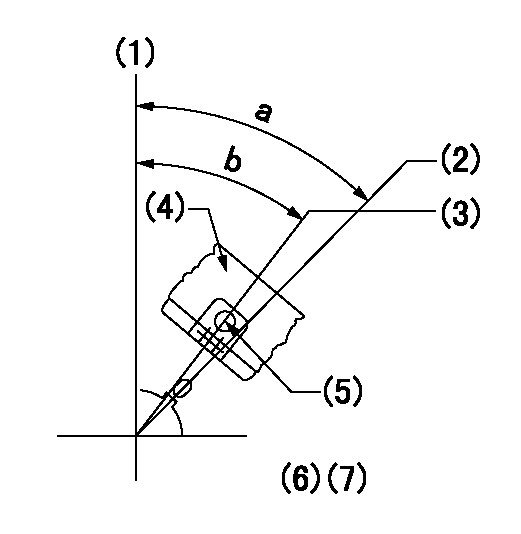

Speed control lever angle

F:Full speed

I:Idle

(1)Viewed from feed pump side.

(2)Use the hole at R = aa

(3)Stopper bolt set position 'H'

----------

aa=37.5mm

----------

a=34deg+-5deg b=(42deg)+-3deg

----------

aa=37.5mm

----------

a=34deg+-5deg b=(42deg)+-3deg

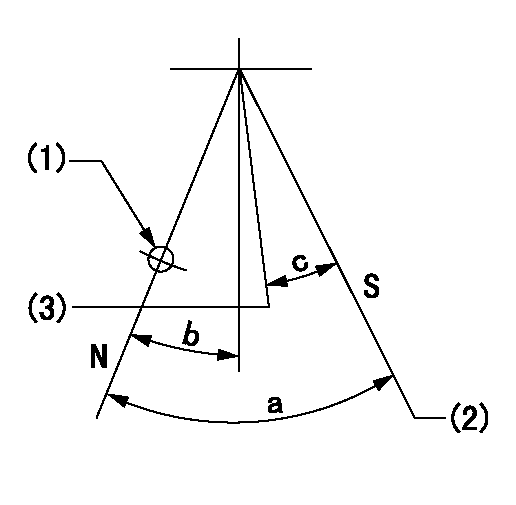

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

(3)Normal engine position (Rack position corresponding to dd)

----------

aa=54mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

----------

aa=54mm bb=1100r/min cc=3.5+-0.3mm dd=18mm

----------

a=41deg+-5deg b=5.5deg+-5deg c=(31deg)

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)At the No 1 cylinder's beginning of injection position, stamp an aligning mark on the damper to align with the pointer's groove.

(4)Damper

(5)Pointer

(6)B.T.D.C.: aa

(7)Pre-stroke: bb

----------

aa=4deg bb=8.5+-0.03mm

----------

a=(45deg) b=(44deg)

----------

aa=4deg bb=8.5+-0.03mm

----------

a=(45deg) b=(44deg)

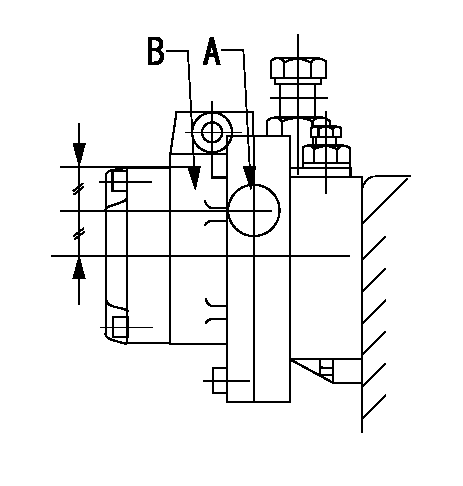

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=335r/min Ra=8.3+-0.1mm

----------

----------

N1=335r/min Ra=8.3+-0.1mm

----------

0000002301 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(13.3)+1.5mm

----------

----------

N1=1100r/min Ra=R1(13.3)+1.5mm

----------

Information:

PROBLEM

The existing diesel exhaust fluid manifold can fail on certain 2570D, 2670D, 563D, and 573D Wheel Feller Bunchers, and 525D, 535D, 545D, and 555D Wheel Skidders. If the existing DEF manifold fails it can lead to inducements and eventual engine shutdown.

AFFECTED PRODUCT

Model Identification Number

2570D D2500112-00114

2670D D2600208-00211

525D GKP00477-00524, 527

535D MTP00386-00448, 450-453

545D KGP00254-00284, 287

555D PGY00153-00159

563D D6300115-00146

573D D7300209-00226

PARTS NEEDED

Qty

Part Number Description

1 3915262 GASKET

1 5280527 MANIFOLD GP

1 DCUSOFTWARE DCU SOFTWARE

1 ENGSOFTWARE ENGINE SOFTWARE

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 29% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Update the Engine and DCU software files to the latest available in SIS Web. Replace the existing diesel exhaust fluid manifold with the 528-0527 diesel exhaust fluid manifold. Use a new 391-5262 gasket when installing a new manifold.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-6000 hrs,

0-36 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

6001-8000 hrs,

37-48 mo 33.0% 50.0% 0.0% 0.0% 50.0% 50.0%

This is a 2.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 108822-2720?

Group cross 108822-2720 ZEXEL

Mitsubishi

Mitsubishi

108822-2720

INJECTION-PUMP ASSEMBLY