Information injection-pump assembly

ZEXEL

108622-3880

1086223880

HINO

220401862A

220401862a

Rating:

Cross reference number

ZEXEL

108622-3880

1086223880

HINO

220401862A

220401862a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

33

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

6.4

6.37

6.43

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(15.9)

Vist

V

1.47

1.47

1.47

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

226

224

228

Max. variation between cylinders

%

0

-2

2

Basic

*

PS407980-224*

V

2.2+-0.0

1

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_02

Rack position

(6.4)

Vist

V

2.9

2.8

3

Pump speed

r/min

425

425

425

Average injection quantity

mm3/st.

16.5

15.5

17.5

Max. variation between cylinders

%

0

-15

15

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

6.3+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

0000001201

Pre-stroke

mm

6.4

6.37

6.43

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

11.5

11

12

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.4

2.35

2.45

Output voltage

V

2.95

2.94

2.96

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.4

6.37

6.43

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

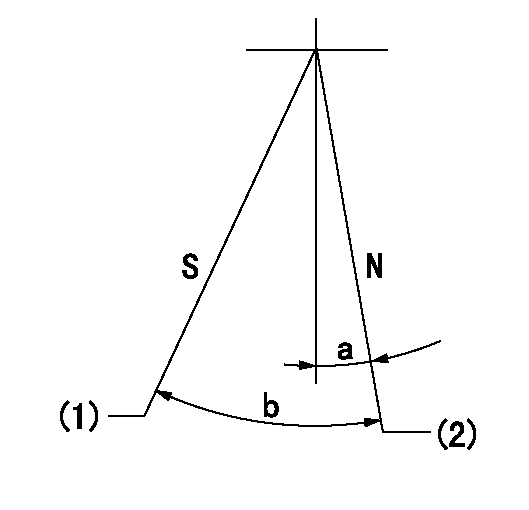

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=1mm bb=18.5+-0.2mm

----------

a=0deg+-5deg b=34deg+-5deg

----------

aa=1mm bb=18.5+-0.2mm

----------

a=0deg+-5deg b=34deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=6.4+-0.03mm

----------

a=(20deg)

----------

aa=6.4+-0.03mm

----------

a=(20deg)

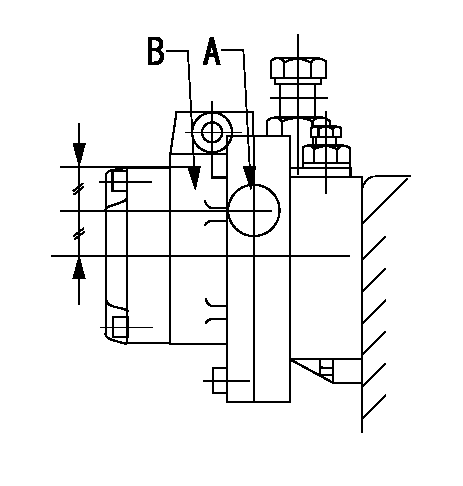

0000001501

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

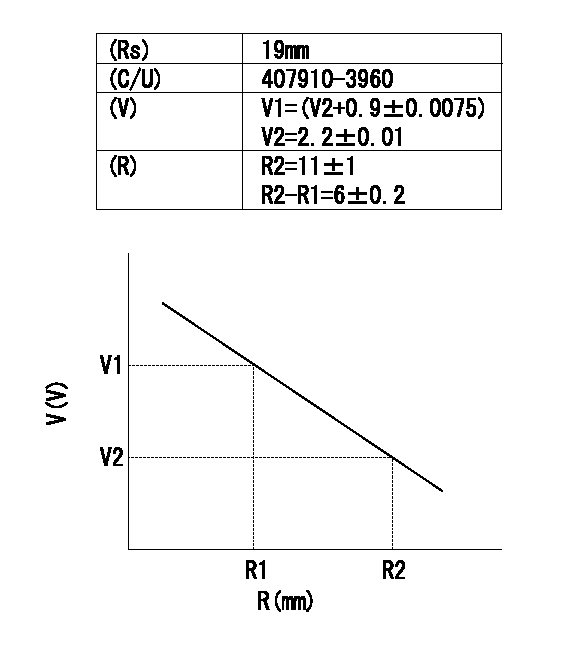

0000001701

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Use fuel consumption or service hours, whichever occurs first, to determine maintenance intervals. Experience has shown that maintenance intervals are most accurately scheduled on the basis of fuel consumed rather than service hours.Daily

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Clutch - Check/Adjust/Lubricate Air Starter & Air Tank (if equipped) - Check Engine Air Cleaner - Check service indicator SR4 Generator - Inspect/CheckEvery 1,900 L (500 gal) of Fuel or 50 Service Hours*

Dust Collector - Clean Light Duty Air Cleaner (If Equipped) - ReplaceEvery 4,250 L (1,100 gal) of Fuel or 125 Service Hours*

Clutch - Check/Adjust/Lubricate Generator Space Heaters - CheckEvery 8,500 L (2,200 gal) of Fuel or 250 Service Hours*

Scheduled Oil Sampling (S O S)1 - Obtain Sample Engine Oil and Filter(s)1 - Change Crankcase Breather1 - Clean Engine Valve Lash (Between First 250 and 1000 Service Hours Only)1 - Check/Adjust Cooling System - Test for supplemental coolant additive concentration Fuel System - Clean/Replace filters, Drain water from fuel tank Radiator Fins, Aftercooler, Belts, and Hoses - Inspect/Check Fan Drive Bearing - Lubricate Batteries - Clean/Check Magnetic Pickup (At First Oil Change Only - Inspect/Clean1These maintenance requirements are to be performed between the 250 and the 1000 Service Hour interval for engines equipped with turbochargers (T, TA & ATAAC) ONLY. Refer to 500 Hour interval for Naturally Aspirated (NA) Engines.Every 17,000 L (4,500 gal) of Fuel or 500 Service Hours (NA Only)*

Scheduled Oil Sampling (S O S) - Obtain Sample Engine Oil and Filter(s) - Change Crankcase Breather - Clean Engine Valve Lash (Between First 500 and 1000 Service Hours Only) - Check/AdjustEvery 34,000 L (9,000 gal) of Fuel or 1000 Service Hours*

Engine Protection Devices - Inspect SR4 Generator and Control Panel - Inspect Fuel Control Linkage - LubricateEvery 67,000 L (18,000 gal) of Fuel or 2000 Service Hours*

Engine Valve Lash, Valve Rotators, Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust Fuel Injection Nozzles - Test/Clean/Replace Turbocharger - Inspect Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect SR4 Generator - Check/Inspect Clean/LubricateEvery 91,000 L (24,000 gal) of Fuel or 3000 Service Hours or Two Years*

Cooling System - Add Extender (Extended Life Coolant Only) - Cooling System - Drain/Clean/Replace Coolant - Conventional Coolant/Antifreeze Only Water Pump Seal - Inspect/Replace Hoses - Replace Thermostat - ReplaceEvery 136,000 L (36,000 gal) of Fuel or 4000 Service Hours*

Magnetic Pickup - Inspect/Clean SR4 Generator - Check/Inspect/Clean/LubricateEvery 204,000 L (54,000 gal) of Fuel or 6,000 Service Hours or Four Years

Cooling System - Drain/Flush/Replace Coolant (Extended Life Coolant Only)*Perform previous maintenance interval items first.

Walk-Around Inspection - Inspect engine for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Clutch - Check/Adjust/Lubricate Air Starter & Air Tank (if equipped) - Check Engine Air Cleaner - Check service indicator SR4 Generator - Inspect/CheckEvery 1,900 L (500 gal) of Fuel or 50 Service Hours*

Dust Collector - Clean Light Duty Air Cleaner (If Equipped) - ReplaceEvery 4,250 L (1,100 gal) of Fuel or 125 Service Hours*

Clutch - Check/Adjust/Lubricate Generator Space Heaters - CheckEvery 8,500 L (2,200 gal) of Fuel or 250 Service Hours*

Scheduled Oil Sampling (S O S)1 - Obtain Sample Engine Oil and Filter(s)1 - Change Crankcase Breather1 - Clean Engine Valve Lash (Between First 250 and 1000 Service Hours Only)1 - Check/Adjust Cooling System - Test for supplemental coolant additive concentration Fuel System - Clean/Replace filters, Drain water from fuel tank Radiator Fins, Aftercooler, Belts, and Hoses - Inspect/Check Fan Drive Bearing - Lubricate Batteries - Clean/Check Magnetic Pickup (At First Oil Change Only - Inspect/Clean1These maintenance requirements are to be performed between the 250 and the 1000 Service Hour interval for engines equipped with turbochargers (T, TA & ATAAC) ONLY. Refer to 500 Hour interval for Naturally Aspirated (NA) Engines.Every 17,000 L (4,500 gal) of Fuel or 500 Service Hours (NA Only)*

Scheduled Oil Sampling (S O S) - Obtain Sample Engine Oil and Filter(s) - Change Crankcase Breather - Clean Engine Valve Lash (Between First 500 and 1000 Service Hours Only) - Check/AdjustEvery 34,000 L (9,000 gal) of Fuel or 1000 Service Hours*

Engine Protection Devices - Inspect SR4 Generator and Control Panel - Inspect Fuel Control Linkage - LubricateEvery 67,000 L (18,000 gal) of Fuel or 2000 Service Hours*

Engine Valve Lash, Valve Rotators, Fuel Ratio Control, Set Point, and Low Idle - Check/Adjust Fuel Injection Nozzles - Test/Clean/Replace Turbocharger - Inspect Engine Mounts - Inspect Crankshaft Vibration Damper - Inspect SR4 Generator - Check/Inspect Clean/LubricateEvery 91,000 L (24,000 gal) of Fuel or 3000 Service Hours or Two Years*

Cooling System - Add Extender (Extended Life Coolant Only) - Cooling System - Drain/Clean/Replace Coolant - Conventional Coolant/Antifreeze Only Water Pump Seal - Inspect/Replace Hoses - Replace Thermostat - ReplaceEvery 136,000 L (36,000 gal) of Fuel or 4000 Service Hours*

Magnetic Pickup - Inspect/Clean SR4 Generator - Check/Inspect/Clean/LubricateEvery 204,000 L (54,000 gal) of Fuel or 6,000 Service Hours or Four Years

Cooling System - Drain/Flush/Replace Coolant (Extended Life Coolant Only)*Perform previous maintenance interval items first.