Information injection-pump assembly

ZEXEL

108622-3170

1086223170

HINO

220008210A

220008210a

Rating:

Service parts 108622-3170 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

9.

_

11.

Nozzle and Holder

23600-2412E

12.

Open Pre:MPa(Kqf/cm2)

16.7{170}/23.5{240}

14.

NOZZLE

Include in #1:

108622-3170

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

108622-3170

1086223170

HINO

220008210A

220008210a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1420

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

31

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

6.4

6.37

6.43

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.9

Pump speed

r/min

550

550

550

Average injection quantity

mm3/st.

204

202

206

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

194

188

200

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

230

225

235

Fixing the lever

*

Boost pressure

kPa

50.7

50.7

Boost pressure

mmHg

380

380

Rack limit

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_04

Adjusting point

D

Rack position

4.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

9

6

12

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

6.3+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_05

Adjusting point

F

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

90

90

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

4+-0.05

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

7.9

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

10.9

Boost pressure

kPa

37.3

37.3

37.3

Boost pressure

mmHg

280

280

280

0000001601

Pre-stroke

mm

6.4

6.37

6.43

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

8.5

8

9

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

4

3.95

4.05

Output voltage

V

2.45

2.44

2.46

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.4

6.37

6.43

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

3.4

Output voltage

V

3

2.98

3

Confirmation

*

_06

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

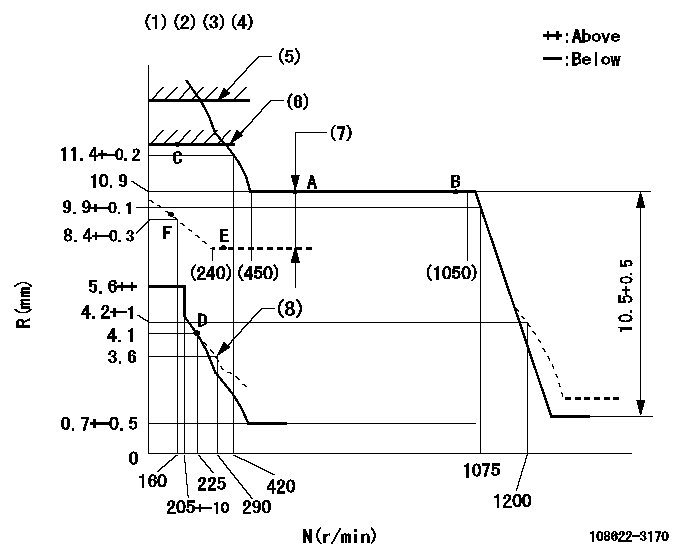

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05

(4)Deliver without the torque control spring operating.

(5)Stop lever setting: R1

(6)RACK LIMIT

(7)Boost compensator stroke: BCL

(8)Damper spring setting

----------

RT=1 TH=2mm R1=12.6+0.5mm BCL=3+-0.1mm

----------

----------

RT=1 TH=2mm R1=12.6+0.5mm BCL=3+-0.1mm

----------

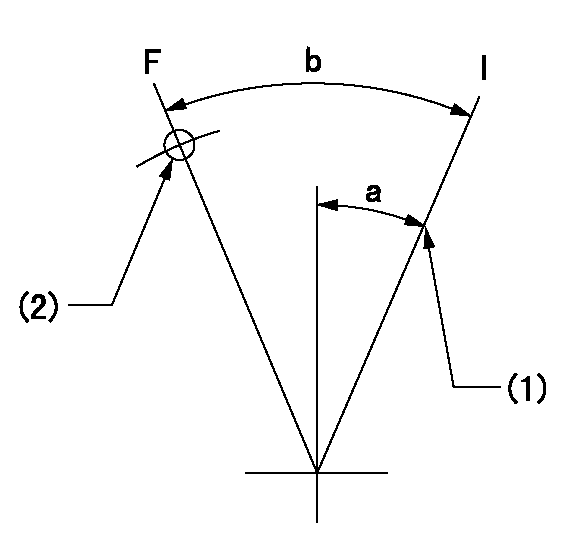

Speed control lever angle

F:Full speed

----------

----------

a=11deg+-5deg

----------

----------

a=11deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=45mm

----------

a=25deg+-5deg b=37.5deg+-3deg

----------

aa=45mm

----------

a=25deg+-5deg b=37.5deg+-3deg

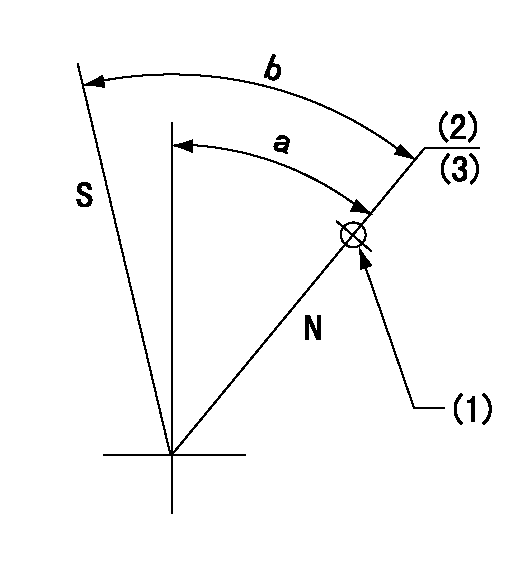

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set stopper screw so that rack position = bb (after setting apply red paint).

(3)Set before governor adjustment.

----------

aa=35mm bb=12.6+0.5mm

----------

a=40deg+-5deg b=43deg+-5deg

----------

aa=35mm bb=12.6+0.5mm

----------

a=40deg+-5deg b=43deg+-5deg

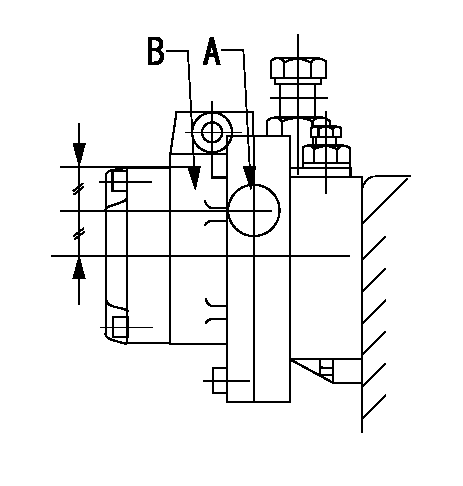

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=6.4+-0.03mm

----------

a=(1deg)

----------

aa=6.4+-0.03mm

----------

a=(1deg)

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack limit adjustment

(1)Mount the joint (B).

(2)Select the shim (D) so that the rack limit's rack position is obtained at that time.

(3)Install the rod (E) to the block (C).

The distance between the pump end face and the rod (E) at rack limit must be L.

2. Rack sensor adjustment (-0020)

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the speed control lever at the full side.

(3)Set at speed N.

(4)Adjust the depth that the bobbin (A) is screwed in so that the control unit's rack sensor output voltage is VR+-0.01 (V), then tighten the nut (F). (If equipped with a boost compensator, perform with boost pressure applied.)

(5)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(6)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

L=38-0.2mm N=1000r/min Ra=(10.9)mm

----------

----------

L=38-0.2mm N=1000r/min Ra=(10.9)mm

----------

Information:

Fuel System Bleeding

Fuel system bleeding(1) Loosen the air vent plug on the fuel filter. (approx. 1.5 turns)(2) Move the priming button for the filter up and down.(3) When fuel flowing from the vent hole no longer contains air bubbles, tighten the vent plug.Inspection and Adjustment of No-Load Minimum (Low Idling) Speed and Maximum Speed

(a) The following adjustments were inspected and set for each engine on the test bench at the factory, and the set bolts are sealed. These settings should be checked and adjusted only at our designated service shop.(b) After the governor parts are adjusted, all external stoppers must be sealed in the same way as when adjustments were made at the factory.(c) Whether the seals are intact or not has important bearing on the validity of claims under warranty. Be sure to seal all the specified sections.(d) When inspecting or adjusting, be ready to operate the engine stop lever manually in case the engine overruns (engine operation at extremely high speed).

Prior to inspection and adjustment, conduct a warm-up operation until the coolant and oil temperatures rise above 70 °C [158 °F].(1) Starting the engine

Inspection and adjustment of no-load minimum (low idling) speed and maximum speed(a) Pull the speed control lever toward the HIGH SPEED side, and operate the starter switch.(b) The engine ignites when the rotation speed reaches approximately 150 min-1, and the engine speed rises. Operate the speed control lever to maintain the engine speed between 800 and 1000 min-1.(c) After the engine speed stabilizes, return the speed control lever to the low idling position.(2) Low idling setting (no-load minimum rotation speed setting)Hold the speed control lever at the position of no-load minimum rotation speed, then secure the lever in that position using the idling adjustment screw.

If there is speed range which causes dangerous torsional vibration, avoid setting the engine speed in that range.

(3) Governor setting (maximum rotation speed setting)(a) Keep the speed control lever at the position of the specified maximum rotation speed.(b) With the speed control lever held in that position, adjust and set the governor set bolt (maximum rotation speed set screw) to the specified rotation speed).Inspection of V-Belt Tension

(1) Press the V-belt at a midpoint between the alternator and crankshaft pulley to check the mount of belt deflection.

Inspection of V-belt tension (2) If the amount of belt deflection does not conform to the standard value, loosen the adjusting bolt and move the alternator to adjust the belt tension.Engine Break-in Operation

When the engine is overhauled, it should be mounted on a dynamometer and operated for break-in and inspection.Starting Up

(1) Before starting the engine, check the levels of coolant, engine oil and fuel, and bleed the fuel and cooling system.(2) With the fuel supply cut off, operate the starter and crank the engine for about 15 seconds to circulate engine oil.(3) Move the speed control lever slightly in the direction for increased fuel (do not move it to "full injection" position), then turn the starter switch key to the [START] position to start

Fuel system bleeding(1) Loosen the air vent plug on the fuel filter. (approx. 1.5 turns)(2) Move the priming button for the filter up and down.(3) When fuel flowing from the vent hole no longer contains air bubbles, tighten the vent plug.Inspection and Adjustment of No-Load Minimum (Low Idling) Speed and Maximum Speed

(a) The following adjustments were inspected and set for each engine on the test bench at the factory, and the set bolts are sealed. These settings should be checked and adjusted only at our designated service shop.(b) After the governor parts are adjusted, all external stoppers must be sealed in the same way as when adjustments were made at the factory.(c) Whether the seals are intact or not has important bearing on the validity of claims under warranty. Be sure to seal all the specified sections.(d) When inspecting or adjusting, be ready to operate the engine stop lever manually in case the engine overruns (engine operation at extremely high speed).

Prior to inspection and adjustment, conduct a warm-up operation until the coolant and oil temperatures rise above 70 °C [158 °F].(1) Starting the engine

Inspection and adjustment of no-load minimum (low idling) speed and maximum speed(a) Pull the speed control lever toward the HIGH SPEED side, and operate the starter switch.(b) The engine ignites when the rotation speed reaches approximately 150 min-1, and the engine speed rises. Operate the speed control lever to maintain the engine speed between 800 and 1000 min-1.(c) After the engine speed stabilizes, return the speed control lever to the low idling position.(2) Low idling setting (no-load minimum rotation speed setting)Hold the speed control lever at the position of no-load minimum rotation speed, then secure the lever in that position using the idling adjustment screw.

If there is speed range which causes dangerous torsional vibration, avoid setting the engine speed in that range.

(3) Governor setting (maximum rotation speed setting)(a) Keep the speed control lever at the position of the specified maximum rotation speed.(b) With the speed control lever held in that position, adjust and set the governor set bolt (maximum rotation speed set screw) to the specified rotation speed).Inspection of V-Belt Tension

(1) Press the V-belt at a midpoint between the alternator and crankshaft pulley to check the mount of belt deflection.

Inspection of V-belt tension (2) If the amount of belt deflection does not conform to the standard value, loosen the adjusting bolt and move the alternator to adjust the belt tension.Engine Break-in Operation

When the engine is overhauled, it should be mounted on a dynamometer and operated for break-in and inspection.Starting Up

(1) Before starting the engine, check the levels of coolant, engine oil and fuel, and bleed the fuel and cooling system.(2) With the fuel supply cut off, operate the starter and crank the engine for about 15 seconds to circulate engine oil.(3) Move the speed control lever slightly in the direction for increased fuel (do not move it to "full injection" position), then turn the starter switch key to the [START] position to start