Information injection-pump assembly

BOSCH

9 400 619 134

9400619134

ZEXEL

108622-2072

1086222072

MITSUBISHI

ME151378

me151378

Rating:

Service parts 108622-2072 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

11.

Nozzle and Holder

ME151252

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/24.5{250}

14.

NOZZLE

Include in #1:

108622-2072

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 134

9400619134

ZEXEL

108622-2072

1086222072

MITSUBISHI

ME151378

me151378

Zexel num

Bosch num

Firm num

Name

108622-2072

9 400 619 134

ME151378 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D24 K 14CJ INJECTION PUMP ASSY TICS HD-TI6M TICS

6D24 K 14CJ INJECTION PUMP ASSY TICS HD-TI6M TICS

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0220

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

31

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

8.5

8.47

8.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

118

116.4

119.6

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.4+-0.5

Pump speed

r/min

390

390

390

Average injection quantity

mm3/st.

14

12

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

8.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

118

117

119

Basic

*

Fixing the lever

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

116.5

112.5

120.5

Fixing the lever

*

PS407980-224*

V

2.45+-0.

01

PS407980-224*

mm

6.1+-0.0

5

0000001601

Pre-stroke

mm

8.5

8.47

8.53

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

8.5

8

9

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.1

6.05

6.15

Output voltage

V

2.45

2.44

2.46

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

8.5

8.47

8.53

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.5

Output voltage

V

3

2.98

3

Confirmation

*

_06

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

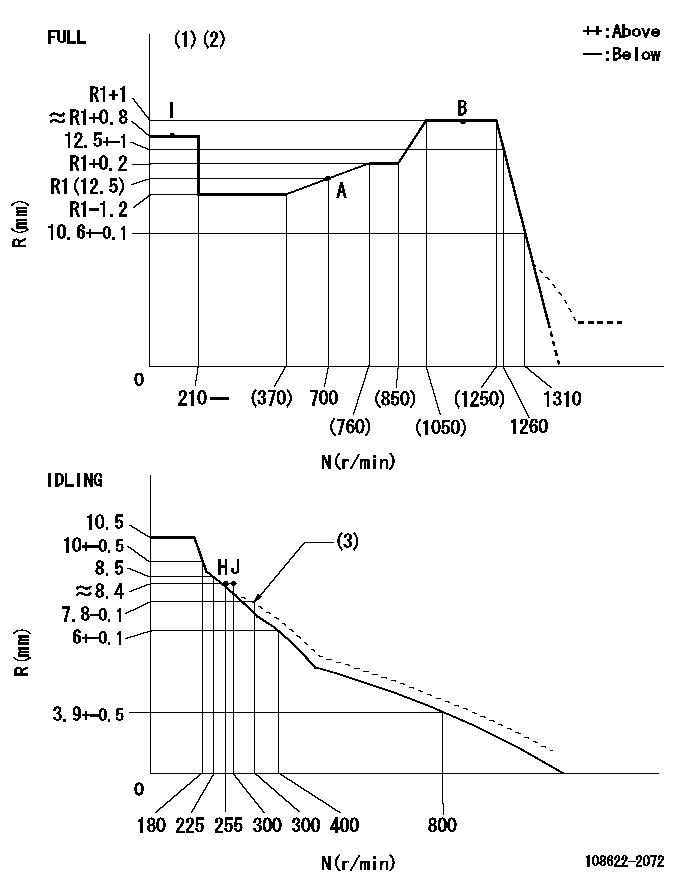

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Damper spring setting

----------

T1=AC06

----------

----------

T1=AC06

----------

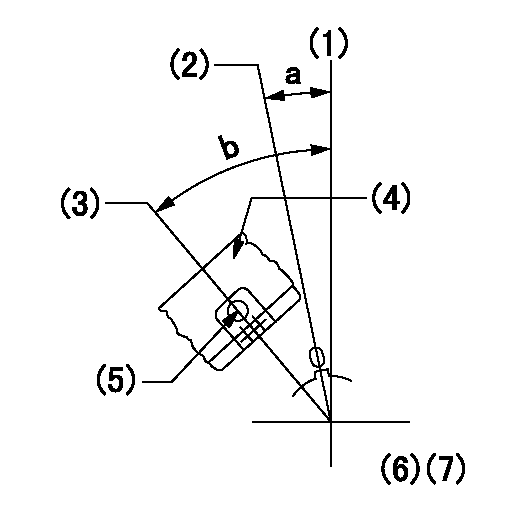

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

(3)Viewed from feed pump side.

----------

aa=45mm

----------

a=33.5deg+-5deg b=30.5deg+-3deg

----------

aa=45mm

----------

a=33.5deg+-5deg b=30.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At pump speed aa and rack position bb, set the stopper bolt. (Confirm non-injection.)

(2)Normal engine position (equivalent to R = cc).

(3)Use the hole above R = dd

----------

aa=1100r/min bb=3.5+-0.3mm cc=18mm dd=33.5mm

----------

a=41deg+-5deg b=25.5deg+-5deg c=(31deg)

----------

aa=1100r/min bb=3.5+-0.3mm cc=18mm dd=33.5mm

----------

a=41deg+-5deg b=25.5deg+-5deg c=(31deg)

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)At the No 1 cylinder's beginning of injection position, stamp an aligning mark on the damper to align with the pointer's groove.

(4)Damper

(5)Pointer

(6)B.T.D.C.: aa

(7)Pre-stroke: bb

----------

aa=4deg bb=8.5+-0.03mm

----------

a=(0deg) b=(44deg)

----------

aa=4deg bb=8.5+-0.03mm

----------

a=(0deg) b=(44deg)

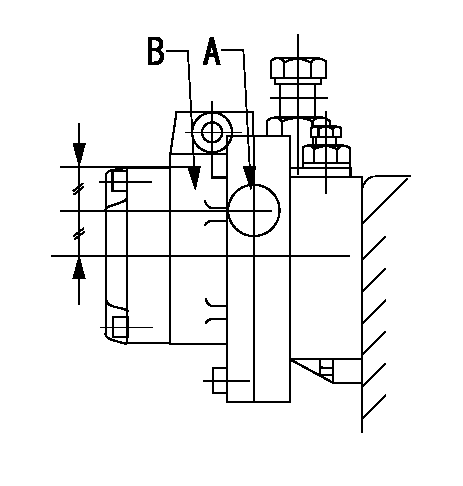

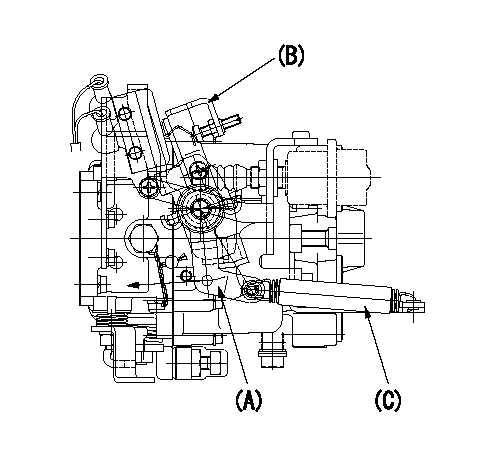

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=8+-0.1mm

----------

----------

N1=325r/min Ra=8+-0.1mm

----------

0000002301 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1100r/min Ra=R1(12.5)+1mm

----------

----------

N1=1100r/min Ra=R1(12.5)+1mm

----------

0000002401 LEVER

Speed lever cancel adjustment procedure (without dashpot)

(A) Top lever

(B) Bottom lever

(C) Return spring

1. At governor adjustment (FULL adjustment)

(1)Set high idle using the lever (A).

(2)Confirm that lever (A) is not cancelled with lever (B).

----------

----------

----------

----------

Information:

Cooling System

The centrifugal-type water pump mounts on the front cover and is belt driven by the crankshaft pulley. The pump has two outlets. Coolant from the outlet on the right side of the pump flows through a passage in the front cover to the left bank of the engine, and coolant from the outlet on the left flows to the right bank.The coolant circulates through the block to the cylinder head. Coolant flows from the heads through connecting sleeves to the return manifold in the front cover. Orifices in the sleeves control the flow from the heads.Part of the coolant to the left bank is diverted from the block to the oil cooler. External lines direct coolant from the block to the cooler and back to the return manifold in the front cover.An internal passage in the front cover directs the coolant from the return manifold to the water pump inlet. If the thermostats are closed the coolant flows to the pump and is recirculated through the engine. If they are open, coolant flows from the return manifold to the radiator and from there to the pump.The radiator is constructed with a top tank above the core and an expansion tank either above or separate from the top tank. A vent tube connects the radiator top tank and the expansion tank. The expansion tank has a shunt line which connects to the water pump inlet. This shunt system maintains a positive, static head of coolant at the pump inlet to prevent cavitation under all operating conditions. When filling the cooling system, coolant from the expansion tank flows through the shunt line to the water pump inlet and fills the engine block from the bottom. By filling the system from the bottom, air in the system is forced out through the top tank, through the vent tube into the expansion tank.The two thermostats are located at the inlet to the water pump. The inlet-regulated cooling system maintains positive coolant temperature control with decreased engine warm up time.When the thermostats are closed, coolant is circulated through the block and heads and back to the water pump by way of an internal passage in the front cover. When the thermostats are open, the bypass flow is restricted and the engine coolant flows through the radiator and returns through the inlet elbow to the water pump. Without the thermostats installed, the coolant will continually bypass the radiator, and overheating will result.Electrical System

The electrical system is a combination of three separate electric circuits: the charging circuit, the starting circuit and the lighting or load circuit. Each circuit is dependent on some of the same components. The battery (batteries), disconnect switch, circuit breaker, ammeter, cables and wires from the battery are common in each of the circuits.The charging circuit is in operation when the engine is operating. The electricity producing (charging) unit is an alternator. A regulator in the circuit senses the state of charge in the battery and regulates the electrical output to

The centrifugal-type water pump mounts on the front cover and is belt driven by the crankshaft pulley. The pump has two outlets. Coolant from the outlet on the right side of the pump flows through a passage in the front cover to the left bank of the engine, and coolant from the outlet on the left flows to the right bank.The coolant circulates through the block to the cylinder head. Coolant flows from the heads through connecting sleeves to the return manifold in the front cover. Orifices in the sleeves control the flow from the heads.Part of the coolant to the left bank is diverted from the block to the oil cooler. External lines direct coolant from the block to the cooler and back to the return manifold in the front cover.An internal passage in the front cover directs the coolant from the return manifold to the water pump inlet. If the thermostats are closed the coolant flows to the pump and is recirculated through the engine. If they are open, coolant flows from the return manifold to the radiator and from there to the pump.The radiator is constructed with a top tank above the core and an expansion tank either above or separate from the top tank. A vent tube connects the radiator top tank and the expansion tank. The expansion tank has a shunt line which connects to the water pump inlet. This shunt system maintains a positive, static head of coolant at the pump inlet to prevent cavitation under all operating conditions. When filling the cooling system, coolant from the expansion tank flows through the shunt line to the water pump inlet and fills the engine block from the bottom. By filling the system from the bottom, air in the system is forced out through the top tank, through the vent tube into the expansion tank.The two thermostats are located at the inlet to the water pump. The inlet-regulated cooling system maintains positive coolant temperature control with decreased engine warm up time.When the thermostats are closed, coolant is circulated through the block and heads and back to the water pump by way of an internal passage in the front cover. When the thermostats are open, the bypass flow is restricted and the engine coolant flows through the radiator and returns through the inlet elbow to the water pump. Without the thermostats installed, the coolant will continually bypass the radiator, and overheating will result.Electrical System

The electrical system is a combination of three separate electric circuits: the charging circuit, the starting circuit and the lighting or load circuit. Each circuit is dependent on some of the same components. The battery (batteries), disconnect switch, circuit breaker, ammeter, cables and wires from the battery are common in each of the circuits.The charging circuit is in operation when the engine is operating. The electricity producing (charging) unit is an alternator. A regulator in the circuit senses the state of charge in the battery and regulates the electrical output to

Have questions with 108622-2072?

Group cross 108622-2072 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

108622-2072

9 400 619 134

ME151378

INJECTION-PUMP ASSEMBLY

6D24

6D24