Information injection-pump assembly

ZEXEL

108621-2022

1086212022

Rating:

Service parts 108621-2022 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

9.

_

11.

Nozzle and Holder

ME120897

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/24.5{250}

15.

NOZZLE SET

Include in #1:

108621-2022

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

108621-2022

1086212022

Zexel num

Bosch num

Firm num

Name

108621-2022

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-7220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

21

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11

Pump speed

r/min

650

650

650

Each cylinder's injection qty

mm3/st.

164.3

160.2

168.4

Basic

*

Fixing the rack

*

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

11.6

9.9

13.3

Fixing the rack

*

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

164.3

163.3

165.3

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.8

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

139.6

133.6

145.6

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Injection quantity adjustment_05

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

180

160

200

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2(R1-1.

6)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(11)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

640--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

590

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

770

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

0000001601

Pre-stroke

mm

5.6

5.57

5.63

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

5

4.5

5.5

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1

1

1.05

Adjustment

*

Remarks

Output voltage V1

Output voltage V1

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.6

2.32

2.88

Output voltage

V

2.8

2.78

2.87

Confirmation

*

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

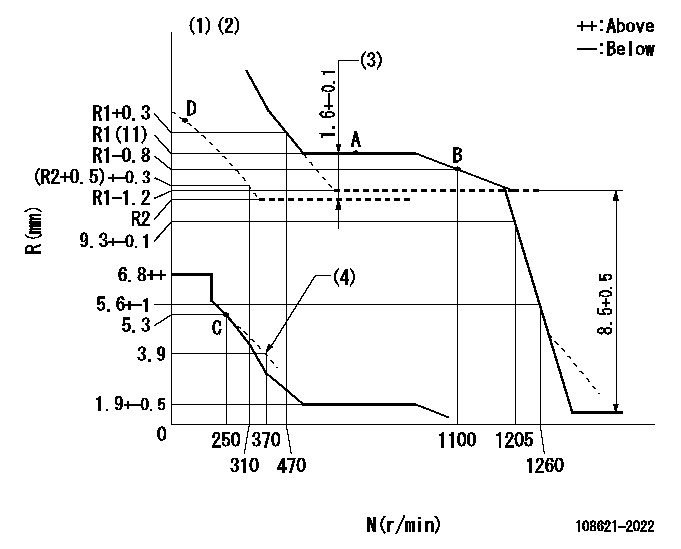

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator cancel stroke: BSL

(3)Boost compensator stroke

(4)Damper spring setting

----------

BSL=1.8mm

----------

----------

BSL=1.8mm

----------

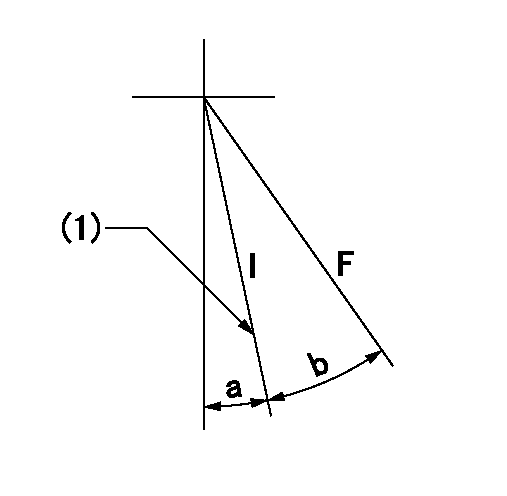

Speed control lever angle

F:Full speed

----------

----------

a=16deg+-5deg

----------

----------

a=16deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=8deg+-5deg b=33.5deg+-3deg

----------

----------

a=8deg+-5deg b=33.5deg+-3deg

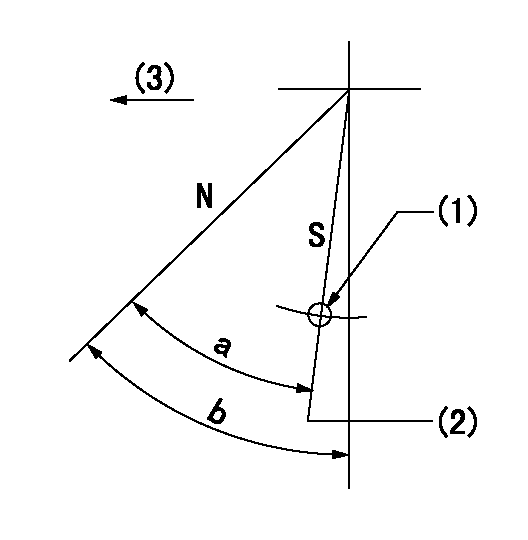

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Rack position bb

(3)Drive side

----------

aa=37mm bb=2.5-0.5mm

----------

a=41.5deg+7deg-5deg b=(41.5deg)+-5deg

----------

aa=37mm bb=2.5-0.5mm

----------

a=41.5deg+7deg-5deg b=(41.5deg)+-5deg

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=5.6+-0.03mm

----------

a=(2deg)

----------

aa=5.6+-0.03mm

----------

a=(2deg)

0000002201 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5.3+-0.1mm

----------

----------

N1=325r/min Ra=5.3+-0.1mm

----------

0000002301 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=650r/min Ra=R1(11)mm

----------

----------

N1=650r/min Ra=R1(11)mm

----------

Information:

Location of Components

Illustration 1 g06494607

Typical example

(A) DEF tank breather

(B) Heater relay

(C) DEF fast fill tank-mounted valve

(D) Plug heater

(E) Heated supply line

(F) DEF fast fill receiver

(G) DEF tank

Illustration 2 g06494608

(C) DEF fast fill tank-mounted valveThe ground level DEF fill system works much like the ground level fast fuel system. DEF fast fill tank-mounted valve (C) is mounted in DEF tank (G). Fast fill tank-mounted valve (C) has a piston that is normally closed with a spring.

Illustration 3 g06516649

(H) O-Ring seal

(J) Flow In

(K) Flow Out

(L) Back cavityNote: O-Ring seal (H) allows small amount of fluid flow.Note: The main flow through the valve is not shown.Note: During normal flow conditions there is no pressure built up in back cavity (L). Back cavity (L) is essentially "open to atmosphere".When filling, the DEF flow opens the piston, past the diverter shield and a portion flows through an orifice in the piston into the float area.

Illustration 4 g06516652

(L) Back cavity

(M) Rolling diaphragm

(N) O-Ring seal

(P) Drain holeNote: O-Ring seal (N) prevents any flow from back cavity (L).Note: Once the float rises, the pressure in back cavity (L) equals the pressure pushing the front of rolling diaphragm (M). Since the area behind rolling diaphragm (M) is greater than the area in front, along with the spring force, diaphragm (M) is held shut.When the tank level causes the float to rise high enough, the orifice is blocked, causing increased pressure on the piston until valve (C) closes. The increased pressure in the fill line then causes the nozzle attached to the receiver to shut off.The nozzle shuts off when the nozzle sees 172 to 200 kPa (25 to 29 psi) resistance. If pressure is not great enough from the source pump/supply at nozzle, there is not enough pressure built up in line between valve and nozzle to trigger nozzle shut off and DEF exits the breather-overfill.Targeted flow for the DEF supply pump should be 45 L/min (12 US gpm). Excessive flow can lead to premature shut-off of DEF nozzle.DEF tank valve (C), supply line (E), and DEF fast fill receiver (F) are electrically heated based on ambient temperature, battery, and alternator loads controlled through heater relay (B). For heated DEF hose repair kit, refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines".Note: If receiver (F) and supply line (E) on machine are drained for storage, the system must be refilled via the ground fill connection. The system is refilled to ensure that plug heater (D) in receiver (F) remains submerged in DEF fluid during the heating operation.

Plug heater (D) probe must be submerged at least 80% in DEF fluid to prevent overheating that could lead to plug heater (D) failing.

Illustration 1 g06494607

Typical example

(A) DEF tank breather

(B) Heater relay

(C) DEF fast fill tank-mounted valve

(D) Plug heater

(E) Heated supply line

(F) DEF fast fill receiver

(G) DEF tank

Illustration 2 g06494608

(C) DEF fast fill tank-mounted valveThe ground level DEF fill system works much like the ground level fast fuel system. DEF fast fill tank-mounted valve (C) is mounted in DEF tank (G). Fast fill tank-mounted valve (C) has a piston that is normally closed with a spring.

Illustration 3 g06516649

(H) O-Ring seal

(J) Flow In

(K) Flow Out

(L) Back cavityNote: O-Ring seal (H) allows small amount of fluid flow.Note: The main flow through the valve is not shown.Note: During normal flow conditions there is no pressure built up in back cavity (L). Back cavity (L) is essentially "open to atmosphere".When filling, the DEF flow opens the piston, past the diverter shield and a portion flows through an orifice in the piston into the float area.

Illustration 4 g06516652

(L) Back cavity

(M) Rolling diaphragm

(N) O-Ring seal

(P) Drain holeNote: O-Ring seal (N) prevents any flow from back cavity (L).Note: Once the float rises, the pressure in back cavity (L) equals the pressure pushing the front of rolling diaphragm (M). Since the area behind rolling diaphragm (M) is greater than the area in front, along with the spring force, diaphragm (M) is held shut.When the tank level causes the float to rise high enough, the orifice is blocked, causing increased pressure on the piston until valve (C) closes. The increased pressure in the fill line then causes the nozzle attached to the receiver to shut off.The nozzle shuts off when the nozzle sees 172 to 200 kPa (25 to 29 psi) resistance. If pressure is not great enough from the source pump/supply at nozzle, there is not enough pressure built up in line between valve and nozzle to trigger nozzle shut off and DEF exits the breather-overfill.Targeted flow for the DEF supply pump should be 45 L/min (12 US gpm). Excessive flow can lead to premature shut-off of DEF nozzle.DEF tank valve (C), supply line (E), and DEF fast fill receiver (F) are electrically heated based on ambient temperature, battery, and alternator loads controlled through heater relay (B). For heated DEF hose repair kit, refer to Service Magazine, M0103829, "Repair Kits for Quick Connect Diesel Exhaust Fluid (DEF) Line Fittings Are Now Available for Certain Cat® Machine Engines".Note: If receiver (F) and supply line (E) on machine are drained for storage, the system must be refilled via the ground fill connection. The system is refilled to ensure that plug heater (D) in receiver (F) remains submerged in DEF fluid during the heating operation.

Plug heater (D) probe must be submerged at least 80% in DEF fluid to prevent overheating that could lead to plug heater (D) failing.

Have questions with 108621-2022?

Group cross 108621-2022 ZEXEL

108621-2022

INJECTION-PUMP ASSEMBLY