Information injection-pump assembly

ZEXEL

108621-2020

1086212020

Rating:

Service parts 108621-2020 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

9.

_

11.

Nozzle and Holder

ME060110

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

108621-2020

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

108621-2020

1086212020

Zexel num

Bosch num

Firm num

Name

108621-2020

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-7220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

21

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.2

Pump speed

r/min

650

650

650

Each cylinder's injection qty

mm3/st.

175.4

171

179.8

Basic

*

Fixing the rack

*

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

11.6

9.9

13.3

Fixing the rack

*

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.2)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

175.4

174.4

176.4

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-0.6

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

159.8

153.8

165.8

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Injection quantity adjustment_05

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

180

160

200

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2(R1-1.

6)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(11.2)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

700--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

650

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

850

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

0000001601

Pre-stroke

mm

5.6

5.57

5.63

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

5

4.5

5.5

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1

1

1.05

Adjustment

*

Remarks

Output voltage V1

Output voltage V1

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.6

2.32

2.88

Output voltage

V

2.8

2.73

2.87

Confirmation

*

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

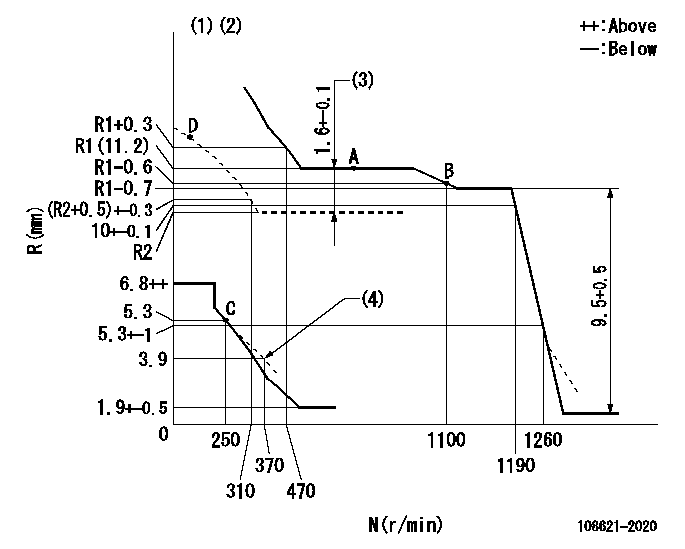

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator cancel stroke: BSL

(3)Boost compensator stroke

(4)Damper spring setting

----------

BSL=1.8mm

----------

----------

BSL=1.8mm

----------

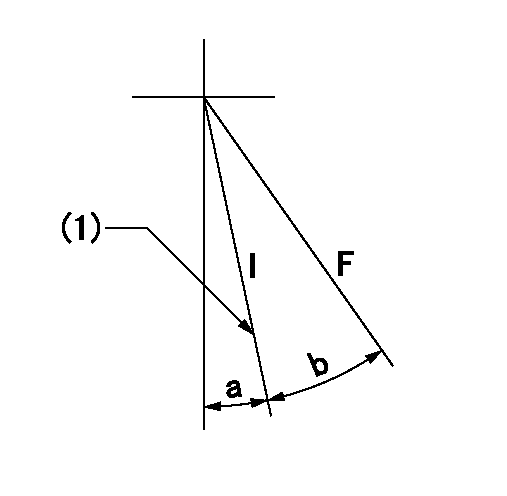

Speed control lever angle

F:Full speed

----------

----------

a=15.5deg+-5deg

----------

----------

a=15.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=8deg+-5deg b=34deg+-3deg

----------

----------

a=8deg+-5deg b=34deg+-3deg

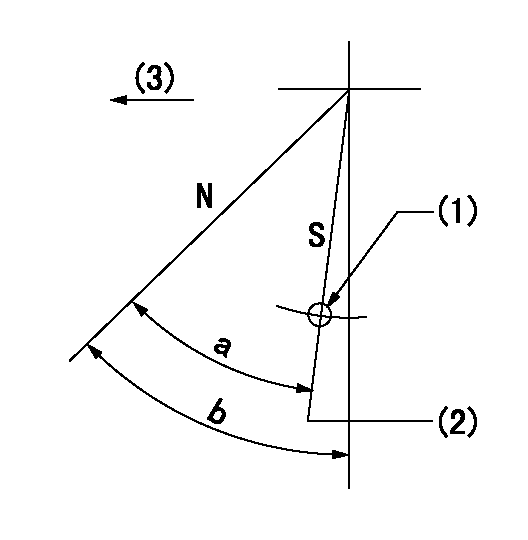

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)R = aa

(2)Rack position bb

(3)Drive side

----------

aa=37mm bb=2.5-0.5mm

----------

a=41.5deg+7deg-5deg b=(41.5deg)+-5deg

----------

aa=37mm bb=2.5-0.5mm

----------

a=41.5deg+7deg-5deg b=(41.5deg)+-5deg

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=5.6+-0.03mm

----------

a=(2deg)

----------

aa=5.6+-0.03mm

----------

a=(2deg)

0000002201 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5.3+-0.1mm

----------

----------

N1=325r/min Ra=5.3+-0.1mm

----------

0000002301 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=650r/min Ra=R1(11.2)mm

----------

----------

N1=650r/min Ra=R1(11.2)mm

----------

Information:

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

The following changes are adaptable to the products within the listed serial numbers, and are effective with all products after the listed serial numbers.Updating to the new components is recommended at the Planned Component Replacement (PCR) for all engines equipped with the 4x4 turbocharger configuration.

Illustration 1 g06495375

(1) New 588-3516 Support As

(D1) Oil Lubrication Jet Orifice 0.8 mm (0.032 inch)

Illustration 2 g06495382

(B) Former 525-1901 Support As

(D2) 1.6 mm (0.063 inch)The new 588-3516 Support As has an oil lubrication jet orifice that has been reduced to 0.8 mm (0.032 inch) from the jet orifice size of 1.6 mm (0.063 inch) in the former support assembly.

Illustration 3 g06495384

(2) New 582-8173 Wiring Harness

Illustration 4 g06495387

(B) Former 415-1169 Wiring HarnessThe new injector wiring harness has the closest zip tie assembly removed as shown in the illustrations above. The improved routing allows for increased harness clearance to the oil lubrication orifice.The table below contains the new part numbers for this change.

Table 1

Required Parts

Item Qty New Part Number Part Name Former Part Number

1 20 588-3516 Support As 525-1901

2 20 582-8173 Wiring Harness 415-1169 The table below contains the effective engine serial numbers for this change.

Table 2

Effective Engine Serial Numbers

S/N:4X41023-UP

S/N:L4G1032-UP

Have questions with 108621-2020?

Group cross 108621-2020 ZEXEL

108621-2020

INJECTION-PUMP ASSEMBLY