Information injection-pump assembly

ZEXEL

108621-2006

1086212006

Rating:

Cross reference number

ZEXEL

108621-2006

1086212006

Zexel num

Bosch num

Firm num

Name

108621-2006

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-7220

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

21

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.1

Pump speed

r/min

650

650

650

Each cylinder's injection qty

mm3/st.

167.5

163.3

171.7

Basic

*

Fixing the rack

*

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.3+-0.5

Pump speed

r/min

250

250

250

Each cylinder's injection qty

mm3/st.

11.6

9.9

13.3

Fixing the rack

*

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.1)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

167.5

166.5

168.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

139

133

145

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Injection quantity adjustment_05

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

165

145

185

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

V1+0.13+

-0.01

PS407980-224*

mm

5.4+-0.0

3

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R2(R1-1.

6)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(11.1)

Boost pressure

kPa

20

20

20

Boost pressure

mmHg

150

150

150

Timer adjustment

Pump speed

r/min

640--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

590

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

840

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

0000001601

Pre-stroke

mm

5.6

5.57

5.63

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

5

4.5

5.5

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1

1

1.05

Adjustment

*

Remarks

Output voltage V1

Output voltage V1

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.6

2.32

2.88

Output voltage

V

2.8

2.73

2.87

Confirmation

*

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

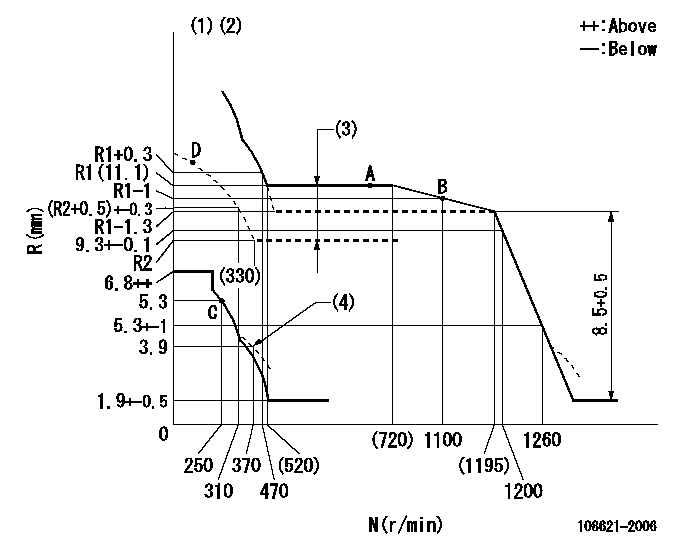

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Boost compensator cancel stroke: BSL

(3)Boost compensator stroke: BCL

(4)Damper spring setting

----------

BSL=1.8mm BCL=1.6+-0.1mm

----------

----------

BSL=1.8mm BCL=1.6+-0.1mm

----------

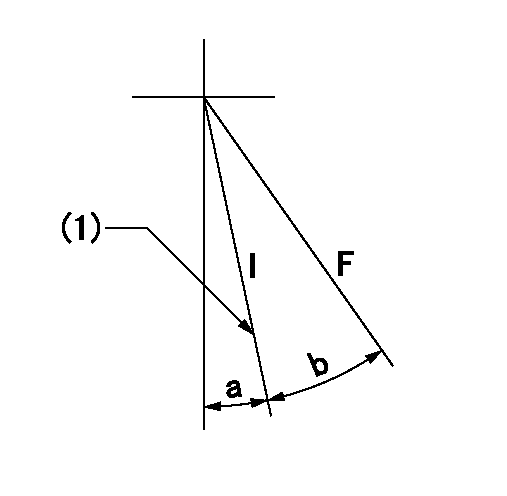

Speed control lever angle

F:Full speed

----------

----------

a=16deg+-5deg

----------

----------

a=16deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=8deg+-5deg b=33.5deg+-3deg

----------

----------

a=8deg+-5deg b=33.5deg+-3deg

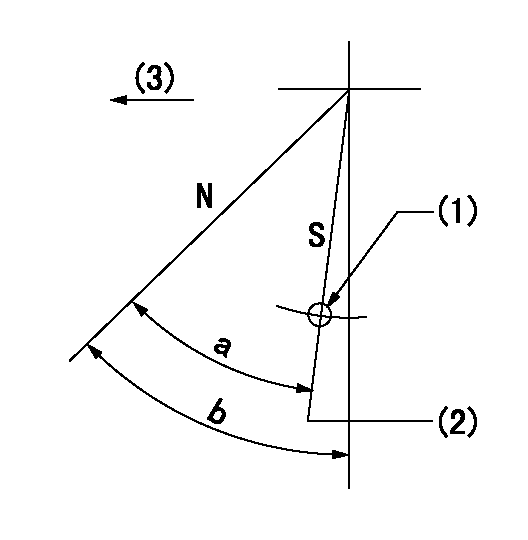

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Rack position bb

(3)Drive side

----------

aa=37mm bb=2.5-0.5mm

----------

a=41.5deg+7deg-5deg b=(59deg)+-5deg

----------

aa=37mm bb=2.5-0.5mm

----------

a=41.5deg+7deg-5deg b=(59deg)+-5deg

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=5.6+-0.03mm

----------

a=(2deg)

----------

aa=5.6+-0.03mm

----------

a=(2deg)

0000002201 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325r/min Ra=5.3+-0.1mm

----------

----------

N1=325r/min Ra=5.3+-0.1mm

----------

0000002301 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=650r/min Ra=R1(11.1)mm

----------

----------

N1=650r/min Ra=R1(11.1)mm

----------

Information:

Personal injury or death can result from improper maintenance procedures. To avoid injury or death, follow the procedures exactly as stated below.

Before servicing/performing maintenance on the machine, electrical power must be physically disconnected; battery plugs must be disconnected from the batteries, or the trailing cable must be unplugged, and warning tags and padlocks shall be applied by a certified electrician. Certified electricians shall perform or direct any electrical work, including any energized testing, repair work in controllers, motors, or other approved compartments, and shall insure that all compartments are properly closed and inspected prior to re-energization. All applicable lock out and tag out procedures must be followed.

Do not operate the machine if any guards or covers are missing or inadequately secured. Personnel could be seriously injured or machine damage may occur.

Observe the safe working load limits of all lifting and blocking devices and keep a safe distance from suspended/blocked loads. Personnel may be seriously injured or killed by falling loads.

Required Parts

Table 2

Required Parts

Item Qty Part Number Part Name

1 1 574-7991 Film Field Rework Procedure

Illustration 1 g06471195

DEF injector hose connector contacting the clearance hole

Visually inspect the DEF injector clearance hole for evidence of rub and wear for the DEF injector hose connector.

Illustration 2 g06480781

Clearance hole before grinding

Illustration 3 g06471198

Detail of area A

(D1) 12.1 mm (0.48 inch)

(D2) 75 mm (2.9 inch)

(D3) 50 mm (1.96 inch)

Illustration 4 g06471200

(D4) 50 mm (1.96 inch)

(D5) 12.6 mm (0.49 inch)

(D6) 11.7 mm (0.46 inch)

(D7) 75 mm (2.9 inch)

(D8) Radius is 35 mm (1.4 inch)

If evidence of contact is found, remove the hose connector from the DEF injector. Use die-grinder to increase size of the clearance hole from outside of the machine. Refer to the dimensions that are provided in Illustration 3 and Illustration 4.Note: To prevent unexpected lowering of the lift arms, use a lift arm safety brace to lock the lift arms in raised position. Refer to Operation and Maintenance Manual , SEBU9084 , "Loader Lift Arm Brace Operation".

Illustration 5 g06471201

DEF hose reconnected to outer connector

After the clearance hole is increased, connect the hose connector for DEF to the outer connector on the DEF injector. Verify the clearance between the frame and the DEF hose connector.

Illustration 6 g06471202

Increased clearance hole

Rotate hose connector towards front of machine. Refer to Illustration 6 for proper orientation. The increased hole is large enough to provide clearance for the hose connector.

Illustration 7 g06471206

(1) 574-7991 Film

Paint any bare metal to prevent rust and cover the clearance hole with film (1).

Have questions with 108621-2006?

Group cross 108621-2006 ZEXEL

108621-2006

INJECTION-PUMP ASSEMBLY