Information injection-pump assembly

ZEXEL

108621-0030

1086210030

Rating:

Cross reference number

ZEXEL

108621-0030

1086210030

Zexel num

Bosch num

Firm num

Name

108621-0030

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4120

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED4 control unit part number

407915-0

590

RED4 rack sensor specifications

mm

19

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

33

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

6.4

6.37

6.43

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(15.2)

PWM

%

73.6

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

170

168

172

Max. variation between cylinders

%

0

-4

4

Basic

*

PS407980-224*

V

2.2+-0.0

1

PS407980-224*

mm

4+-0.05

Injection quantity adjustment_02

Rack position

(7.4)

PWM

%

29.9+-2.

8

Pump speed

r/min

295

295

295

Average injection quantity

mm3/st.

16.6

15.6

17.6

Max. variation between cylinders

%

0

-10

10

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

6.3+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Governor adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Governor adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

0000001201

Pre-stroke

mm

6.4

6.37

6.43

Remarks

When the timing sleeve is pushed up

When the timing sleeve is pushed up

_02

Connector angle

deg.

11.5

11

12

Remarks

When the eccentric pin is tightened

When the eccentric pin is tightened

_03

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.4

2.35

2.45

Output voltage

V

2.95

2.94

2.96

Adjustment

*

_04

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

6.4

6.37

6.43

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_05

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

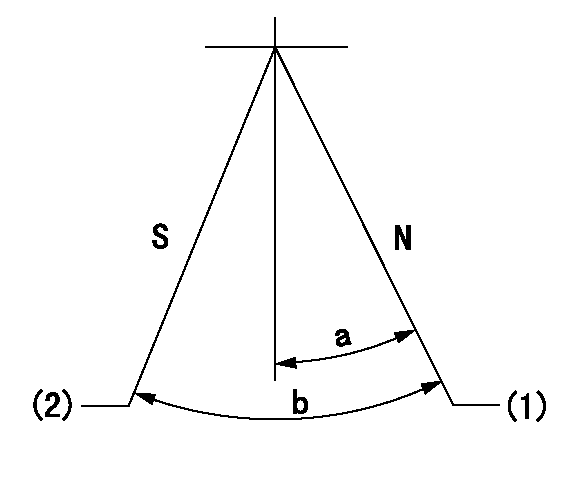

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=20deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=20deg+-5deg b=37deg+-5deg

0000000901

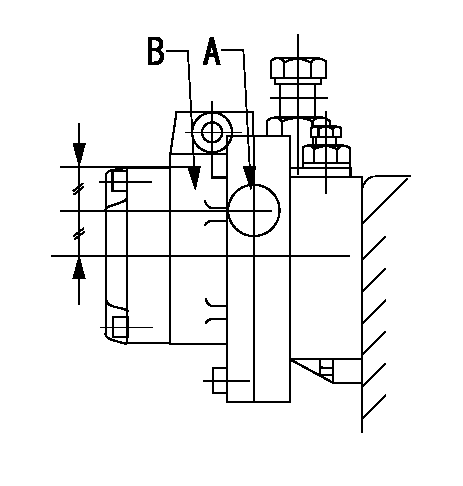

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=6.4+-0.03mm

----------

a=(20deg)

----------

aa=6.4+-0.03mm

----------

a=(20deg)

0000001501

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000001701

(PWM) Pulse width modulation (%)

(R) Rack position (mm)

Rack sensor output characteristics

1. Rack limit adjustment

(1)Measure the rack position R2 for PWM a2%.

(2)Confirm that it is within the range R2 = 15+-1 mm.

(3)Measure the rack position R1 at PWM a %.

(4)Confirm that it is within the range R2 - R1 = 10+-0.1 mm.

2. Check the limp home operation.

(1)Move the switch box's limp home switch to the limp home side.

(2)Confirm rack position L1 (mm ) and L2 (mm) for PWM in the above table.

3. Check the pull down operation.

(1)Confirm that the rack position is 19 mm at PWM B%.

(2)In the conditions described in the above table, move the switch box's pull down switch to the pull down side and confirm that the rack position momentarily becomes 1 mm or less.

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5% B=95%

----------

----------

a1=16.25% a2=72.5% L1=1--mm L2=19++mm A=5% B=95%

----------

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some instances of the following active diagnostic codes:

651-6 Engine Injector Cylinder #01 : Current Above Normal

652-6 Engine Injector Cylinder #02 : Current Above Normal

653-6 Engine Injector Cylinder #03 : Current Above Normal

654-6 Engine Injector Cylinder #04 : Current Above NormalThe engine will be derated and will be difficult to start.Solution

Follow the correct troubleshooting procedure for the active diagnostic codes. Refer to Troubleshooting, Injector Solenoid - Test.

If the troubleshooting procedure identifies suspect injectors, use the electronic service tool to generate a Product Status Report (PSR). Select the "Histogram" option when generating the PSR.

Install replacement 418-3229 Fuel Injector Gp, as required. Refer to Disassembly and Assembly, Electronic Unit Injector - Remove and Disassembly and Assembly, Electronic Unit Injector - Install.

Use 169-7372 Fluid Sampling Bottles to obtain a fuel sample from the following locations:

Machine fuel tank ( 355 mL (12 oz)

Bulk fuel supply tank ( 355 mL (12 oz)Analyze the fuel sample. The fuel samples will need to be analyzed for the following properties:

Lubricity Wear Scar - "ASTM D6079" or "ISO 12156"

Density at 15° C (59° F) - "ASTM D1298", "ASTM D4052", "ISO 3675", or "ISO 12185"

Kinematic Viscosity at 40° C (104° F) - "ASTM D445", "ISO 3448", or "ISO 3104"

Sulfur - "ASTM D4294", "ASTM D5185", "ASTM D5453", "ASTM D26222", "ISO 20846", or "ISO 20884"

Water by Distillation - "ASTM D95", "ASTM D6304", "ASTM D2709", "ASTM D1796", or "ISO3734"

Cloud Point - "ASTM D2500" or "ISO 3015"

FAME - "EN 14078", "ASTM D7806", or "ASTM D7371"

Oxidation Stability - "EN 14112"

Copper - "ASTM D7111"

Sodium - "ASTM D7111"

Zinc - "ASTM D7111"

Calcium - "ASTM D7111"

Potassium - "ASTM D7111"Provide the results of the fuel sample.

Retain any removed injectors. The injectors will be requested for return through the "Send It Back" (SIB) process.

Submit the PSR along with TIB Media number, M0085259, and CPI number 386169 through "CPI Feedback" within the Service Information Management System (SIMSi).

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been some instances of the following active diagnostic codes:

651-6 Engine Injector Cylinder #01 : Current Above Normal

652-6 Engine Injector Cylinder #02 : Current Above Normal

653-6 Engine Injector Cylinder #03 : Current Above Normal

654-6 Engine Injector Cylinder #04 : Current Above NormalThe engine will be derated and will be difficult to start.Solution

Follow the correct troubleshooting procedure for the active diagnostic codes. Refer to Troubleshooting, Injector Solenoid - Test.

If the troubleshooting procedure identifies suspect injectors, use the electronic service tool to generate a Product Status Report (PSR). Select the "Histogram" option when generating the PSR.

Install replacement 418-3229 Fuel Injector Gp, as required. Refer to Disassembly and Assembly, Electronic Unit Injector - Remove and Disassembly and Assembly, Electronic Unit Injector - Install.

Use 169-7372 Fluid Sampling Bottles to obtain a fuel sample from the following locations:

Machine fuel tank ( 355 mL (12 oz)

Bulk fuel supply tank ( 355 mL (12 oz)Analyze the fuel sample. The fuel samples will need to be analyzed for the following properties:

Lubricity Wear Scar - "ASTM D6079" or "ISO 12156"

Density at 15° C (59° F) - "ASTM D1298", "ASTM D4052", "ISO 3675", or "ISO 12185"

Kinematic Viscosity at 40° C (104° F) - "ASTM D445", "ISO 3448", or "ISO 3104"

Sulfur - "ASTM D4294", "ASTM D5185", "ASTM D5453", "ASTM D26222", "ISO 20846", or "ISO 20884"

Water by Distillation - "ASTM D95", "ASTM D6304", "ASTM D2709", "ASTM D1796", or "ISO3734"

Cloud Point - "ASTM D2500" or "ISO 3015"

FAME - "EN 14078", "ASTM D7806", or "ASTM D7371"

Oxidation Stability - "EN 14112"

Copper - "ASTM D7111"

Sodium - "ASTM D7111"

Zinc - "ASTM D7111"

Calcium - "ASTM D7111"

Potassium - "ASTM D7111"Provide the results of the fuel sample.

Retain any removed injectors. The injectors will be requested for return through the "Send It Back" (SIB) process.

Submit the PSR along with TIB Media number, M0085259, and CPI number 386169 through "CPI Feedback" within the Service Information Management System (SIMSi).

Have questions with 108621-0030?

Group cross 108621-0030 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

108621-0030

INJECTION-PUMP ASSEMBLY