Information injection-pump assembly

ZEXEL

107692-5220

1076925220

Rating:

Cross reference number

ZEXEL

107692-5220

1076925220

Zexel num

Bosch num

Firm num

Name

107692-5220

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407910-3

03*

Selector switch no.

01

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

15

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

5.1

5.07

5.13

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

14.4

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

113

111

115

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.1+-0.0

5

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.4+-0.5

Pump speed

r/min

465

465

465

Average injection quantity

mm3/st.

22.5

20.7

24.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

5+-0.03

PS407910-303*

V

V1+0.05+

-0.01

PS407910-303*

mm

5+-0.03

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(14.4)

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

113

112

114

Basic

*

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.1+-0.0

5

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1-2.05

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

103.5

99.5

107.5

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.1+-0.0

5

Injection quantity adjustment_05

Adjusting point

C

Rack position

(R2-0.5)

Pump speed

r/min

350

350

350

Average injection quantity

mm3/st.

47.4

45.4

49.4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.1+-0.0

5

Boost compensator adjustment

Pump speed

r/min

350

350

350

Rack position

(R2-0.5)

Boost pressure

kPa

6.7

5.4

8

Boost pressure

mmHg

50

40

60

Boost compensator adjustment_02

Pump speed

r/min

350

350

350

Rack position

R2(R1-3.

95)

Boost pressure

kPa

14.7

14.7

14.7

Boost pressure

mmHg

110

110

110

0000001601

CU407980-224*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2

1.95

2.05

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.1

5.07

5.13

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_03

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

_04

CU407910-303*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2

1.95

2.05

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_05

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.1

5.07

5.13

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_06

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

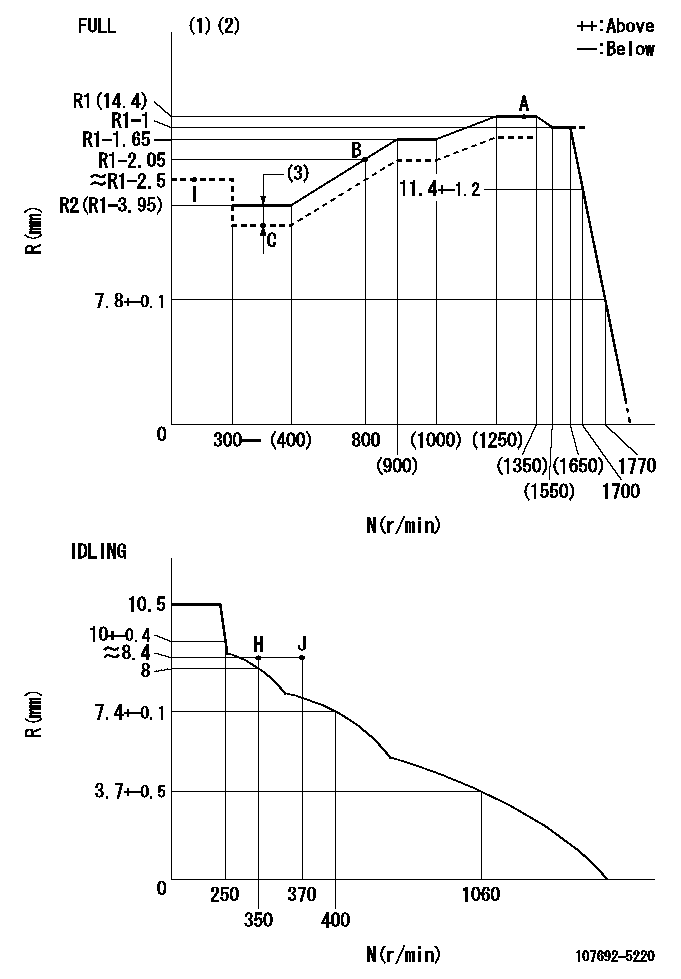

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AF93 BCL=(0.5)+-0.1mm

----------

----------

T1=AF93 BCL=(0.5)+-0.1mm

----------

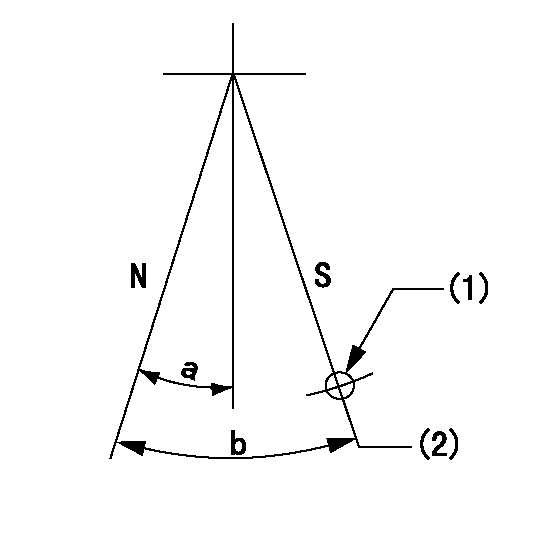

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt set position 'H'

----------

aa=93.5mm

----------

a=17deg+-5deg b=(38deg)+-3deg

----------

aa=93.5mm

----------

a=17deg+-5deg b=(38deg)+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt at rack position = bb (non-injection rack position), (speed = cc)

----------

aa=37mm bb=1.5+-0.3mm cc=0r/min

----------

a=20deg+-5deg b=45deg+-5deg

----------

aa=37mm bb=1.5+-0.3mm cc=0r/min

----------

a=20deg+-5deg b=45deg+-5deg

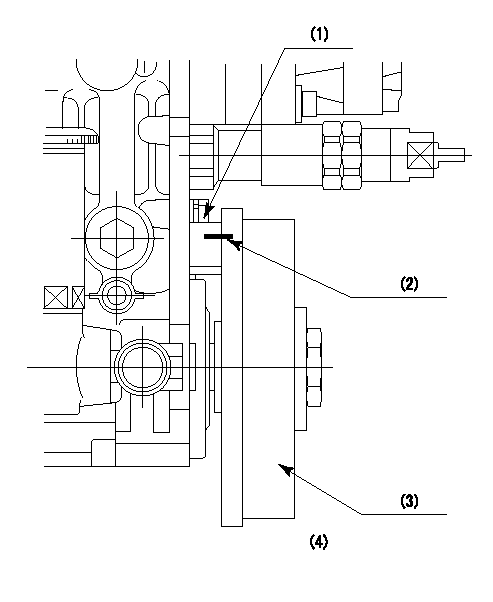

0000001301

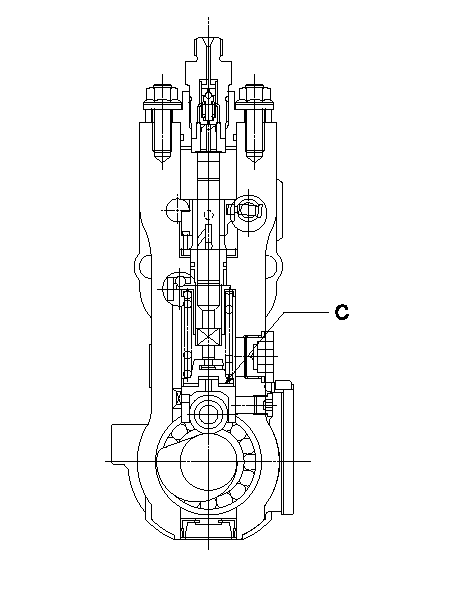

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)Pre-stroke: aa

(4)-

----------

aa=5.1+-0.03mm

----------

a=(20deg)

----------

aa=5.1+-0.03mm

----------

a=(20deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

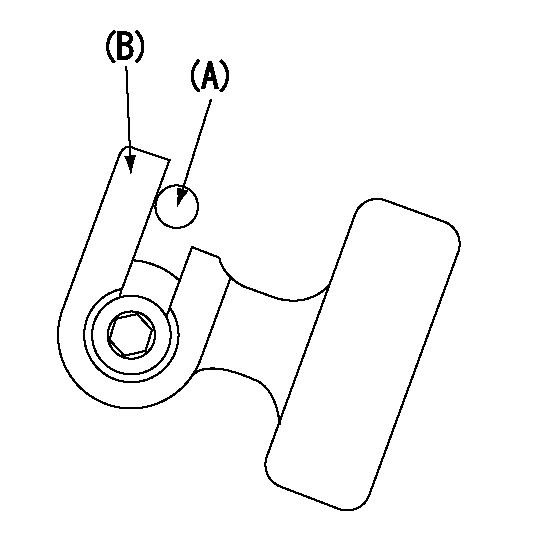

0000001701

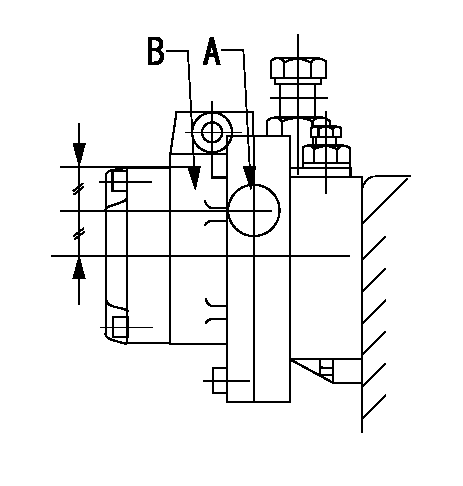

A : Stopper pin

B: Connector

----------

----------

----------

----------

0000001801

C:Shim

----------

----------

----------

----------

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1300r/min Ra=R1(14.4)mm

----------

----------

N1=1300r/min Ra=R1(14.4)mm

----------

Information:

Oil Filters (1), Crankcase Drain (2), Oil Filler (3), Oil Level Gauge (4), Fuel Filters & Priming Pump (5), Air Cleaner with Service Indicator (6), Aftercooler (7), Turbochargers (8), Crankcase Breather with Element (9), Alternator (10), Electronic Governing/Control Module (11), Primary Fuel Filter (12), Oil Cooler (13), Magnetic Speed Sensor (14), Jacket Water Pump (15), Jacket Water Heater (16), Fumes Disposal Drain (17), Ether Canister Bracket (18), Starting Motor (19) and Cooling System Drain (20).

Main Control (GSC) Panel (21), Emergency Stop Pushbutton (22), Engine Control Switch (23), Alarm Module (24).Engine Description

Caterpillar 3412 Generator Set Engines are 27 liter (1649 cu. in.), 137 mm (5.4 in.) bore and 152.4 mm (6.0 in.) stroke, four cycle, 12 cylinder, 65 degree vee diesel design. The engine is available in twin turbocharged or series turbocharged arrangements with jacket water aftercooling and direct fuel injection.The engine and components are designed for high power output. The reduced size and weight plus increased fuel economy provide maximum performance and lower cost per unit of power. The 3412 Generator Set is offered at 1500 rpm, 50 Hz and 1800 rpm, 60 Hz arrangements with various output power ratings. Contact your Caterpillar dealer for information on these power ratings.Larger diameter plungers and a higher injection rate camshaft are incorporated in the valve train/fuel system. The fuel lines are made of high strength steel and the ends of the lines have collared washers to increase reliability. The cooling system has a gear driven centrifugal water pump, two thermostats (one for each bank) which regulate engine coolant temperature, and an oil cooler.The engine lubricating oil, which is both cooled and filtered, is supplied by a gear driven pump. Bypass valves provide unrestricted flow of lubrication oil to engine parts when oil viscosity is high, or either the oil cooler or oil filter elements should become plugged.The 3412 Generator Set Engine is electronically governed and features an exclusive electronic Engine Control Module (ECM). The ECM is a microprocessor-based system that provides full range isochronous speed governing which can operate in speed droop with a zero to ten percent adjustment range.The ECM also provides a cold mode starting strategy, air to fuel ratio control for transient smoke limiting, automatic turbocharger boost pressure and rack position sensor calibration, engine protection and diagnostics.The 3412 engines are equipped with the Electronic Modular Control Panel (EMCP II). The EMCP II is the next generation of engine/generator controls for more accurate, reliable monitoring of engine operating parameters and generator AC voltage metering.The SR4 generator features single bearing, wye connected, brushless, permanent magnet excited designed to match the output characteristics of the engine. These packaged generator sets are designed, manufactured and tested in accordance with ISO 9001 to ensure the highest possible quality on a worldwide basis.Engine efficiency and engine performance and efficiency of emissions controls depend on adherence to proper operation and maintenance recommendations, and the use of recommended fuels, coolants and lubrication oils. To minimize expenses and provide maximum utilization and performance of your

Have questions with 107692-5220?

Group cross 107692-5220 ZEXEL

Nissan-Diesel

Nissan-Diesel

107692-5220

INJECTION-PUMP ASSEMBLY