Information injection-pump assembly

ZEXEL

107692-2160

1076922160

Rating:

Cross reference number

ZEXEL

107692-2160

1076922160

Zexel num

Bosch num

Firm num

Name

107692-2160

INJECTION-PUMP ASSEMBLY

14CG TICS MD-TI6 TICS

14CG TICS MD-TI6 TICS

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-2

470

RED3 rack sensor specifications

mm

15

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

17

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(11)

Vist

V

1.8

1.8

1.8

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

120.5

119.5

121.5

Max. variation between cylinders

%

0

-3

3

Basic

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

5

Injection quantity adjustment_02

Rack position

(6)

Vist

V

2.8

2.7

2.9

Pump speed

r/min

440

440

440

Average injection quantity

mm3/st.

15.5

13.7

17.3

Max. variation between cylinders

%

0

-15

15

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

5.5+-0.0

3

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

0000001201

CU407980-224*

*

Actuator advancing type

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_03

CU407980-224*

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

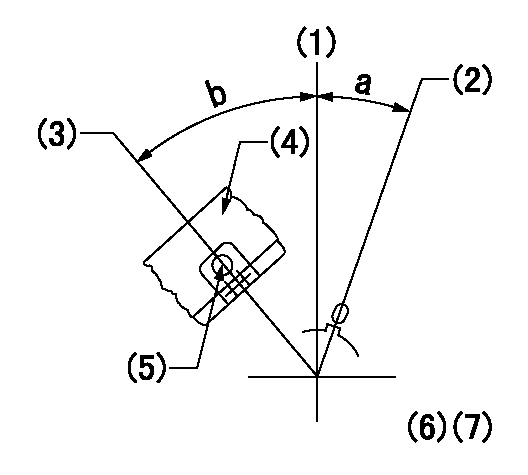

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=1mm bb=16mm

----------

a=31deg+-5deg b=29deg+-5deg

----------

aa=1mm bb=16mm

----------

a=31deg+-5deg b=29deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)At the No 1 cylinder's beginning of injection position, stamp an aligning mark on the damper to align with the pointer's groove.

(4)Damper

(5)Pointer

(6)B.T.D.C.: aa

(7)Pre-stroke: bb

----------

aa=2deg bb=5.6+-0.03mm

----------

a=(0deg) b=(40deg)

----------

aa=2deg bb=5.6+-0.03mm

----------

a=(0deg) b=(40deg)

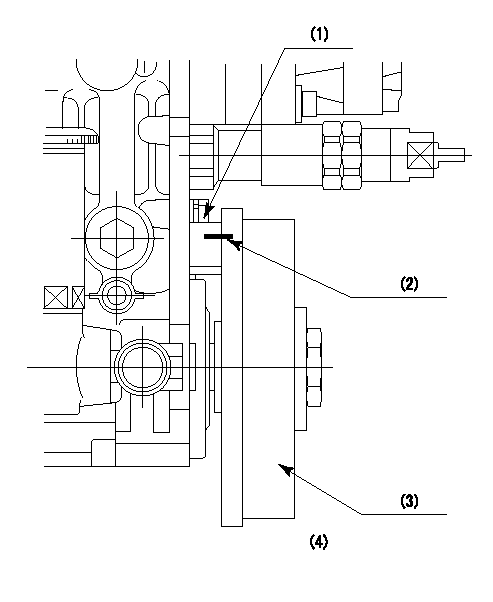

Stop lever angle

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

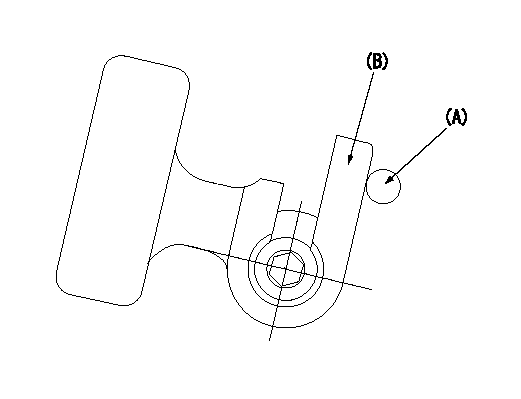

0000001301

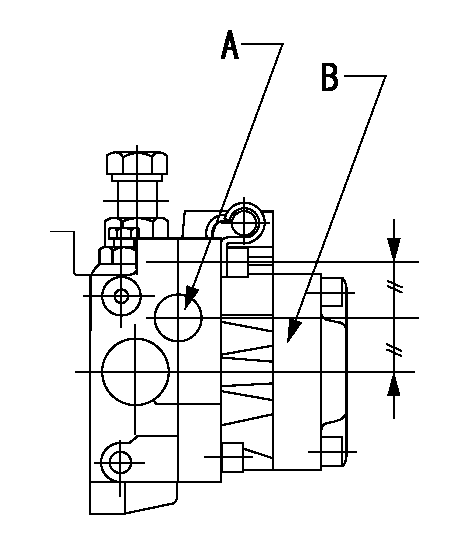

A : Stopper pin

B: Connector

----------

----------

----------

----------

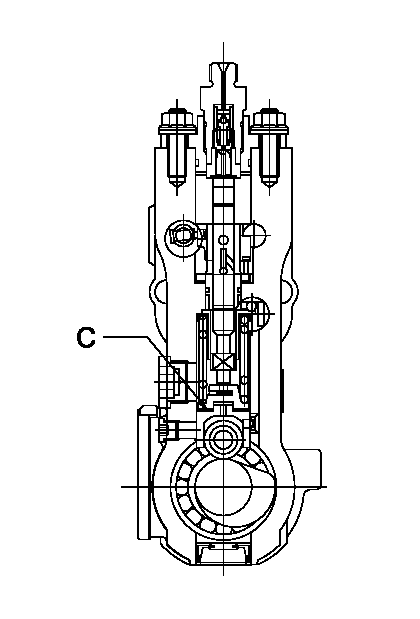

0000001401

C:Shim

----------

----------

----------

----------

0000001501

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully clockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the counterclockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000001701

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 15 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

0000001901 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (154610-0620)

(1)At governor side rack sensor output voltage V1, adjust the bobbin (A) so that the drive side rack sensor output voltage is VR+-0.01.

(2)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

V1=1V

----------

----------

V1=1V

----------

Information:

Adjustment of the fuel system outside Caterpillar specified limits will not improve fuel efficiency and could result in damage to the engine.

If you feel you have a vehicle performance problem, first consider the impact of vehicle efficiency and operating characteristics (vehicle speed, design, etc.), on power demand before questioning engine performance.In the case of poor fuel economy, the engine is not likely to be the cause without the presence of excessive exhaust smoke and/or a significant loss of power.If you feel you have a valid engine performance problem, contact an authorized Caterpillar dealer for assistance. If your engine is under warranty, then the Caterpillar warranty or extended service coverage (if purchased) will cover the cost of resolving a valid engine performance deficiency. Refer to the Warranty Section in this publication and your Caterpillar dealer for details.However, if the engine is not found at fault, all costs incurred will be the responsibility of the owner.Performance Analysis Report (PAR)

PAR complements a good preventive maintenance program. PAR analysis can monitor the condition of your engine and to determine if your engine is operating at peak efficiency.PAR reflects the results of various tests normally conducted by your Caterpillar dealer for the purpose of:* confirming your engine is operating efficiently and within specification.* identifying potential problems.* determining components or systems that should be adjusted, replaced, etc.Approximately eighty to 85% of your truck engine's total operation and maintenance cost is the cost of fuel. Therefore, substantial cost reductions can be achieved by keeping your engine operating at peak efficiency. Fuel consumption and performance of your engine is affected by vehicle specifications, how it is operated and condition of the engine. Each plays an important part in minimizing your total owner and operating cost.Do not attempt to use PAR until the first engine oil change. This allows for sufficient break-in of the engine, drive train and tires. Fuel rate and turbocharger boost will be measured under load at five engine speeds and compared to factory specifications. Fuel rate and boost are the primary indicators of your engine's performance and the analysis of this data will help pinpoint potential problems faster.Wheel horsepower (kW) will also be recorded during the initial PAR test to establish your truck's exact wheel horsepower (kW) over its full operating range. This power can then be compared to the power of subsequent PAR tests. Power available at the wheels is not only the result of the condition of the engine, but also the transmission, drive axle(s), brakes, tires and engine drive accessories.Consult your Caterpillar dealer for complete information and assistance in establishing a PAR program for your engine.Refer to Form LEDT4211, PEDP0026 and/or Performance Troubleshooting Manual, Form SENR4249 or your Caterpillar dealer for more information on PAR.Contact your nearest Caterpillar dealer for information on PAR and the location of the nearest, approved dynamometer.

Have questions with 107692-2160?

Group cross 107692-2160 ZEXEL

107692-2160

INJECTION-PUMP ASSEMBLY