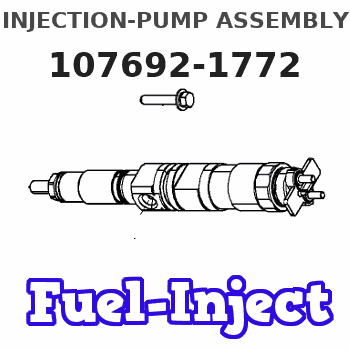

Information injection-pump assembly

BOSCH

9 400 613 195

9400613195

ZEXEL

107692-1772

1076921772

ISUZU

8976024172

8976024172

Rating:

Service parts 107692-1772 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

11.

Nozzle and Holder

8-97600-813-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}/22.1{225}

14.

NOZZLE

Include in #1:

107692-1772

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

107692-1772

9 400 613 195

8976024172 ISUZU

INJECTION-PUMP ASSEMBLY

6HH1 K 14CG INJECTION PUMP ASSY TICS MD-TI6 TICS

6HH1 K 14CG INJECTION PUMP ASSY TICS MD-TI6 TICS

Information:

If you operate the engine until the turbocharger fails, you could cause severe damage to the turbocharger's compressor wheel and/or your engine. For example: severe damage to the turbocharger compressor wheel could cause parts from the compressor wheel to enter the engine cylinder and cause additional damage to the piston, valve and cylinder head.Maintenance Options

Repair Kits - These useful kits can be obtained from your Caterpillar dealer. These kits include all the necessary parts and instructions to repair your turbocharger in either your own maintenance shop or at your servicing dealer's facility. Repair kits simplify parts ordering, help speed repairs and reduce parts costs. Remanufactured - This process uses manufacturing techniques and procedures to restore your turbocharger to "like-new" performance capability. This process always involves an end product which conforms to the manufacturer's original functional specification. New - Replace with a new turbocharger.Before deciding which method is best, you should make sure you have considered all of the options and costs associated with repair. Some considerations are: * The costs associated with using separate parts from inventory versus the cost of a repair kit.* Downtime costs while the product is being rebuilt or repaired.* Total parts and labor costs for repairs versus the actual Remanufactured cost.* Remanufactured components from Caterpillar are covered by a national factory warranty.Caterpillar Recommendation

To minimize downtime, Caterpillar recommends the use of a Remanufactured turbocharger.There are two levels of pricing for Remanufactured turbochargers.* The first level is primarily based on damage to the turbocharger before failure.* The second level is primarily based on damage to the turbocharger after failure.If you choose to operate your engine until the turbocharger fails, your repair cost could be as much as ten times the repair before failure cost due to additional turbocharger and engine damage that could have been prevented.Refer to the Service Manual for your engine to remove and install the turbocharger.Valve Lash

Check/Adjust

Be sure the engine cannot be started while this maintenance is being performed. To prevent possible injury, do not use the starting motor to turn the flywheel. Hot engine components can cause burns. Allow additional time for the engine to cool before measuring valve clearance.The PEEC uses high voltage to the unit injectors. Disconnect injector enable circuit connector to prevent personal injury. Do not come in contact with the injector terminals while the engine is running.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to engine cylinder head and block temperature.

Adjust the valve clearance to within 0.08 mm (.003 in) of the valve clearance setting given in the Valve Clearance Setting chart above. Rotate the engine crankshaft 360° in the normal crankshaft rotation direction before any adjustments are made.Bridge Adjustment

The valve bridge should be checked and/or adjusted each time valve clearance is chcked and/or adjusted. Valve and valve mechanism components do not always wear evenly which can allow the bridge to be out of adjustment.It is not necessary to remove the rocker

Repair Kits - These useful kits can be obtained from your Caterpillar dealer. These kits include all the necessary parts and instructions to repair your turbocharger in either your own maintenance shop or at your servicing dealer's facility. Repair kits simplify parts ordering, help speed repairs and reduce parts costs. Remanufactured - This process uses manufacturing techniques and procedures to restore your turbocharger to "like-new" performance capability. This process always involves an end product which conforms to the manufacturer's original functional specification. New - Replace with a new turbocharger.Before deciding which method is best, you should make sure you have considered all of the options and costs associated with repair. Some considerations are: * The costs associated with using separate parts from inventory versus the cost of a repair kit.* Downtime costs while the product is being rebuilt or repaired.* Total parts and labor costs for repairs versus the actual Remanufactured cost.* Remanufactured components from Caterpillar are covered by a national factory warranty.Caterpillar Recommendation

To minimize downtime, Caterpillar recommends the use of a Remanufactured turbocharger.There are two levels of pricing for Remanufactured turbochargers.* The first level is primarily based on damage to the turbocharger before failure.* The second level is primarily based on damage to the turbocharger after failure.If you choose to operate your engine until the turbocharger fails, your repair cost could be as much as ten times the repair before failure cost due to additional turbocharger and engine damage that could have been prevented.Refer to the Service Manual for your engine to remove and install the turbocharger.Valve Lash

Check/Adjust

Be sure the engine cannot be started while this maintenance is being performed. To prevent possible injury, do not use the starting motor to turn the flywheel. Hot engine components can cause burns. Allow additional time for the engine to cool before measuring valve clearance.The PEEC uses high voltage to the unit injectors. Disconnect injector enable circuit connector to prevent personal injury. Do not come in contact with the injector terminals while the engine is running.

Measure the valve lash with the engine stopped. To obtain an accurate measurement, allow at least 20 minutes for the valves to cool to engine cylinder head and block temperature.

Adjust the valve clearance to within 0.08 mm (.003 in) of the valve clearance setting given in the Valve Clearance Setting chart above. Rotate the engine crankshaft 360° in the normal crankshaft rotation direction before any adjustments are made.Bridge Adjustment

The valve bridge should be checked and/or adjusted each time valve clearance is chcked and/or adjusted. Valve and valve mechanism components do not always wear evenly which can allow the bridge to be out of adjustment.It is not necessary to remove the rocker

Have questions with 107692-1772?

Group cross 107692-1772 ZEXEL

Isuzu

Isuzu

Isuzu

107692-1772

9 400 613 195

8976024172

INJECTION-PUMP ASSEMBLY

6HH1

6HH1