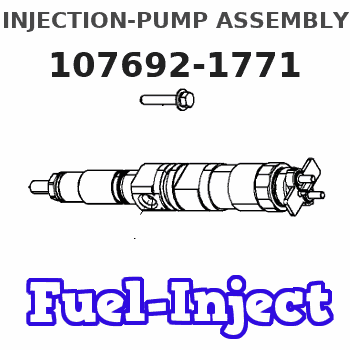

Information injection-pump assembly

BOSCH

F 019 Z10 769

f019z10769

ZEXEL

107692-1771

1076921771

ISUZU

8976024171

8976024171

Rating:

Service parts 107692-1771 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

7.

COUPLING PLATE

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

18.1(185)/22.1(225)

14.

NOZZLE

Include in #1:

107692-1771

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Cooling System

Clean/Flush Coolant

Do not perform this maintenance until you read and understand the material in the Safety and Cooling System Specifications sections of this publication. This procedure is to be used for normal maintenance of cooling system surfaces to return to "like new" condition. For heavy build-up of scale and deposits, a severe acid-type, commercial cleaner or mechanical cleaning will be required.

Typical Example1. Stop the engine and allow to cool. Loosen the radiator filler cap slowly and remove the cap to relieve pressure. 2. Remove the cooling system drain plug(s). Remove the drain plug (1) on bottom of water pump housing and/or radiator.Check water pump breather filter 4N1400 (2) for blockage or debris and replace if necessary.

Right Side View3. Open the cab heater valve to flush coolant from the cab heater. Remove the two block drain plugs from both sides of the engine. Allow coolant to drain.With the recent shortage and higher cost of new antifreeze and the disposal problems of used engine coolant, the interest in recycling the used engine coolant has sharply increased. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems.Filtering methods for reclaiming the used engine coolant do not reduce the level of chemicals in the water. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant. The ethylene glycol and water obtained from this process can be treated with new chemical corrosion inhibitors to provide a like-new coolant.Commercial units are available to do this distillation process. Contact Caterpillar Service Technology Group: Outside Illinois: 1-800-542-TOOLInside Illinois: 1-800-541-TOOLCanada: 1-800-523-TOOLRefer to Service Magazine article dated November 13, 1989 and/or Engine News article dated November 1989 for information regarding disposal and recycling of used coolant.4. Refill the cooling system with clean water mixed with a 6 to 10 percent concentration of Caterpillar Cooling System Cleaner. Install radiator filler cap.Caterpillar Cooling System Cleaner is available through your Caterpillar dealer. A 9-12 gallon (33-47 L) cooling system capacity requires one gallon (3.8 L) of Caterpillar Cooling System Cleaner to accommodate the 6-10 percent concentration.5. Start and run the engine to circulate fluid in the cooling system for 1 1/2 hours.6. Stop the engine, remove radiator filler cap and cooling system drain plugs.7. Drain the cleaning solution. Flush the cooling system with clean water until draining water is clear. Clean and install all drain plugs and/or close the drain valve.8. Mix a solution of acceptable water and Caterpillar Antifreeze (which contains supplemental coolant additive).When NOT using Caterpillar Antifreeze, add 1 U.S. quart (1 L) of Caterpillar Supplemental Coolant Additive for every 8 U.S. gal (30 L) of cooling system capacity OR change maintenance element only (if equipped). Caterpillar Supplemental Coolant Additive or a coolant additive element (if equipped) should only be used when NOT using Caterpillar Antifreeze.Refer to the topic Cooling System Specifications in this publication for all information regarding acceptable water, antifreeze and supplemental coolant additive requirements.9. Fill the cooling system with the coolant solution at 5

Clean/Flush Coolant

Do not perform this maintenance until you read and understand the material in the Safety and Cooling System Specifications sections of this publication. This procedure is to be used for normal maintenance of cooling system surfaces to return to "like new" condition. For heavy build-up of scale and deposits, a severe acid-type, commercial cleaner or mechanical cleaning will be required.

Typical Example1. Stop the engine and allow to cool. Loosen the radiator filler cap slowly and remove the cap to relieve pressure. 2. Remove the cooling system drain plug(s). Remove the drain plug (1) on bottom of water pump housing and/or radiator.Check water pump breather filter 4N1400 (2) for blockage or debris and replace if necessary.

Right Side View3. Open the cab heater valve to flush coolant from the cab heater. Remove the two block drain plugs from both sides of the engine. Allow coolant to drain.With the recent shortage and higher cost of new antifreeze and the disposal problems of used engine coolant, the interest in recycling the used engine coolant has sharply increased. Various methods have been proposed to reclaim used coolant for reuse in engine cooling systems.Filtering methods for reclaiming the used engine coolant do not reduce the level of chemicals in the water. The full distillation procedure is the only method acceptable by Caterpillar to reclaim the used coolant. The ethylene glycol and water obtained from this process can be treated with new chemical corrosion inhibitors to provide a like-new coolant.Commercial units are available to do this distillation process. Contact Caterpillar Service Technology Group: Outside Illinois: 1-800-542-TOOLInside Illinois: 1-800-541-TOOLCanada: 1-800-523-TOOLRefer to Service Magazine article dated November 13, 1989 and/or Engine News article dated November 1989 for information regarding disposal and recycling of used coolant.4. Refill the cooling system with clean water mixed with a 6 to 10 percent concentration of Caterpillar Cooling System Cleaner. Install radiator filler cap.Caterpillar Cooling System Cleaner is available through your Caterpillar dealer. A 9-12 gallon (33-47 L) cooling system capacity requires one gallon (3.8 L) of Caterpillar Cooling System Cleaner to accommodate the 6-10 percent concentration.5. Start and run the engine to circulate fluid in the cooling system for 1 1/2 hours.6. Stop the engine, remove radiator filler cap and cooling system drain plugs.7. Drain the cleaning solution. Flush the cooling system with clean water until draining water is clear. Clean and install all drain plugs and/or close the drain valve.8. Mix a solution of acceptable water and Caterpillar Antifreeze (which contains supplemental coolant additive).When NOT using Caterpillar Antifreeze, add 1 U.S. quart (1 L) of Caterpillar Supplemental Coolant Additive for every 8 U.S. gal (30 L) of cooling system capacity OR change maintenance element only (if equipped). Caterpillar Supplemental Coolant Additive or a coolant additive element (if equipped) should only be used when NOT using Caterpillar Antifreeze.Refer to the topic Cooling System Specifications in this publication for all information regarding acceptable water, antifreeze and supplemental coolant additive requirements.9. Fill the cooling system with the coolant solution at 5