Information injection-pump assembly

BOSCH

9 400 619 010

9400619010

ZEXEL

107692-1344

1076921344

ISUZU

8943907965

8943907965

Rating:

Cross reference number

BOSCH

9 400 619 010

9400619010

ZEXEL

107692-1344

1076921344

ISUZU

8943907965

8943907965

Zexel num

Bosch num

Firm num

Name

107692-1344

9 400 619 010

8943907965 ISUZU

INJECTION-PUMP ASSEMBLY

6HH1 K

6HH1 K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-1820

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

17

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.1

5.07

5.13

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

13.8

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

116

114.4

117.6

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.5+-0.5

Pump speed

r/min

360

360

360

Average injection quantity

mm3/st.

12

10.7

13.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

5+-0.03

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.8)

Pump speed

r/min

850

850

850

Average injection quantity

mm3/st.

116

115

117

Basic

*

Fixing the lever

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1+2.4)

+-0.02

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

121

111

131

Fixing the lever

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.1+-0.0

5

0000001601

CU407980-224*

*

Actuator retarding type

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2

1.95

2.05

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.1

5.07

5.13

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_03

CU407980-224*

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

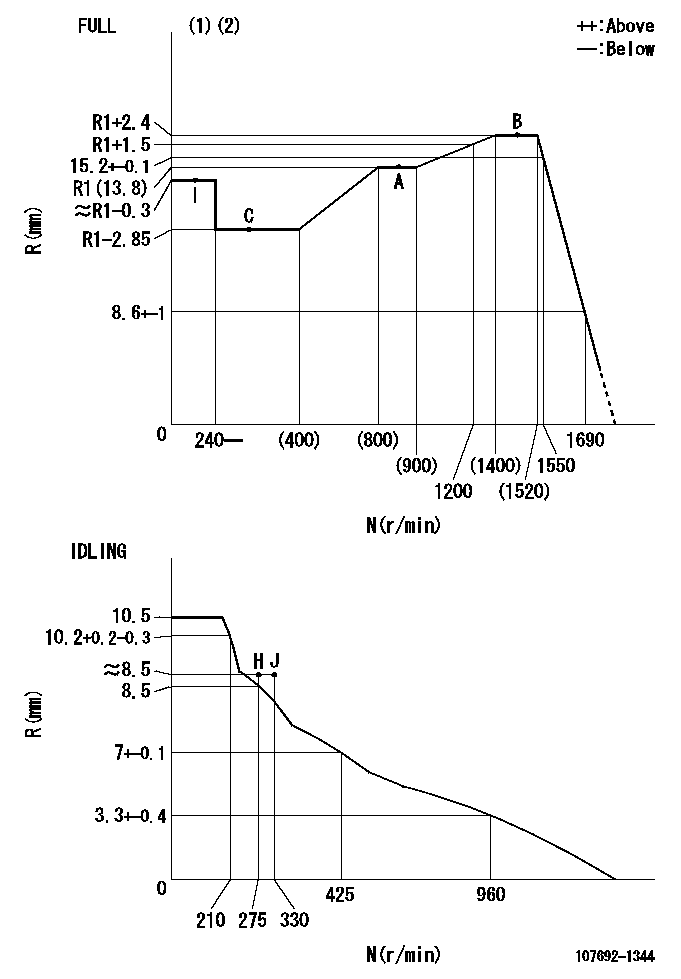

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

----------

T1=AF71

----------

----------

T1=AF71

----------

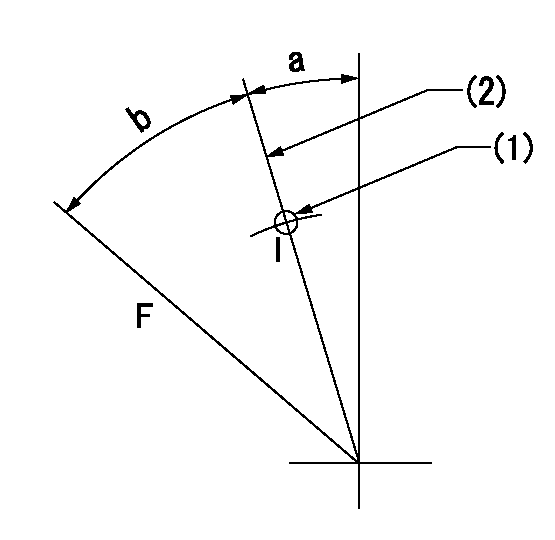

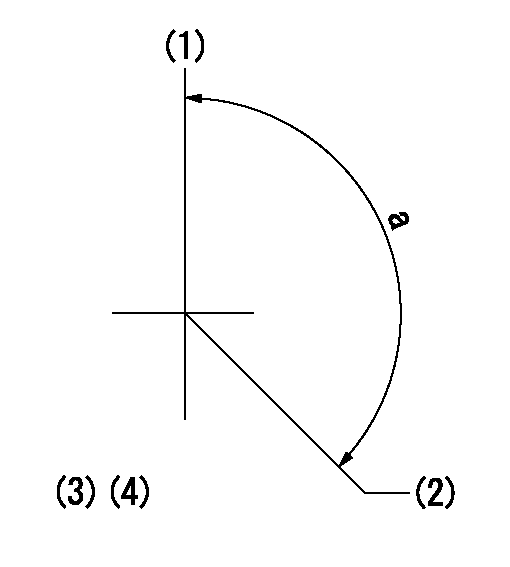

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=1deg+-5deg b=39.5deg+-3deg

----------

aa=35mm

----------

a=1deg+-5deg b=39.5deg+-3deg

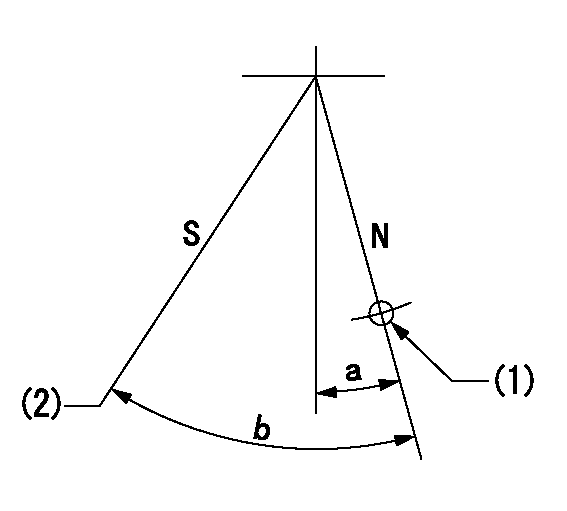

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt at rack position = bb, speed = cc

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=12deg+-5deg b=44deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=12deg+-5deg b=44deg+-5deg

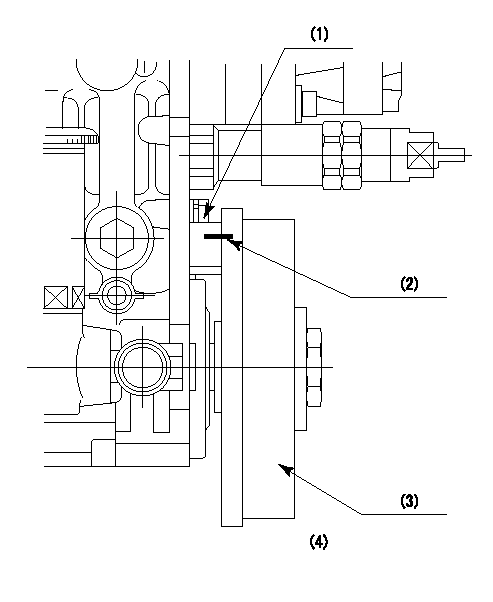

0000001301

(1)Pump vertical direction

(2)Positions of coupling's threaded installation holes at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=6deg bb=5.1+-0.03mm

----------

a=(140deg)

----------

aa=6deg bb=5.1+-0.03mm

----------

a=(140deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

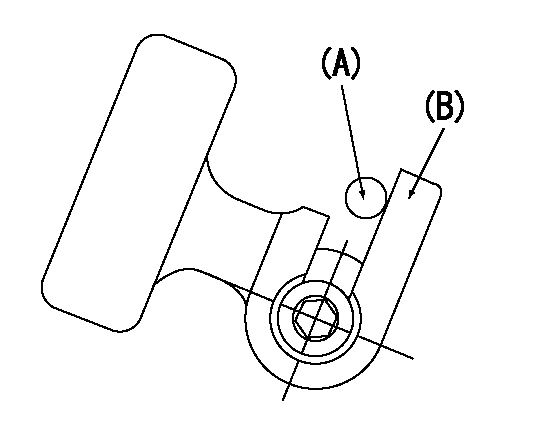

0000001701

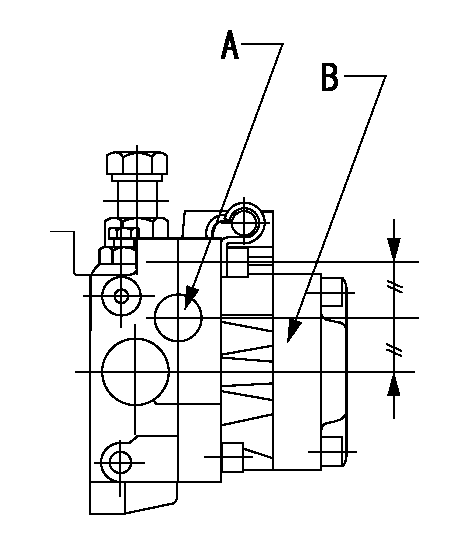

A : Stopper pin

B: Connector

----------

----------

----------

----------

0000001801

C:Shim

----------

----------

----------

----------

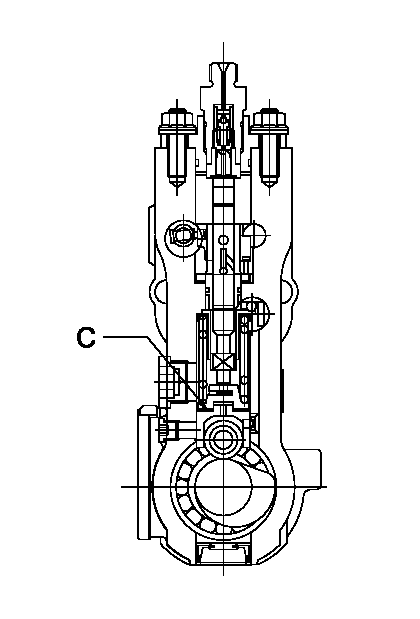

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully clockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the counterclockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

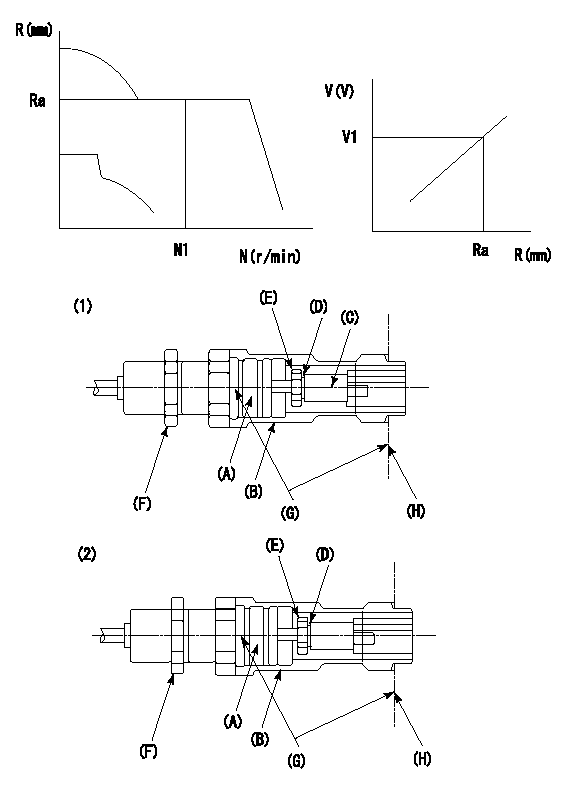

0000002201 RACK SENSOR

G:Red paint

H:Pump end face

P/N: part number of suitable shim

(1)Threaded type rack block

(2)Welded type rack block

Rack sensor adjustment

1. Threaded type rack sensor (-5*20, P type, no TICS rack limit).

(1)Screw in the bobbin (A) until it contacts the joint (B).

(2)Fix the pump lever.

(3)At speed N1 and rack position Ra, adjust the amount that the bobbin is screwed in so that the amp's output voltage is V1.

(4)Fix using the nut (F).

(5)Affix the caution plate to the upper part of the joint (B).

(6)Apply (G) at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the end surface of the pump (H) and the joint (B)

2. Range for screw-in adjustment between the bobbin (A) and the joint (B) is 9 threads.

Screw in to the end from (the position where the bobbin (A) is rotated 9 turns).

Speed N1, rack position Ra, output voltage V1, rack sensor supply voltage 5+-0.01 (V)

----------

Ra=R1(13.8)+2.4mm N1=1450r/min V1=3+-0.01V

----------

----------

Ra=R1(13.8)+2.4mm N1=1450r/min V1=3+-0.01V

----------

Information:

Caterpillar Reference Material

The following literature can be obtained through any Caterpillar dealer. The literature specific for your engine can be found in the Information Section, Product Support topic in this manual.Oil

Oil and Your Engine SEBD0640Question & Answer Booklet PEDP7122Cat Lithium Grease (MPGL) PEHP0003Cat Special Purpose Grease (SPG) PEHP0017How to Take a Good Oil Sample PEHP6001Cat Engine Oil Spec Sheets PEHP7504Cat Diesel Engine Oil Spec Sheets PEHP7505Cat Fluids Selector PEWP9733Fuel

Diesel Fuels and Your Engine SEBD0717Coolant

Know Your Cooling System SEBD0518Coolant and Your Engine SEBD0970Miscellaneous

3406B Industrial and Marine Service Manual SENR3023Index to Guidelines for Reusable Parts and Salvage Operations SEBF8029Storage Procedure for Caterpillar Products SEHS9031The Caterpillar Engine Technical Manual (Volume I) LEO0002The Caterpillar Engine Technical Manual (Volume II) LEO0003All of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM Specs can normally be obtained from your local technological society, library or college or contacting:* American Society for Testing and Materials

1916 Race St.

Philadelphia, PA 19103

(215) 299-5400

Society of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society, or contacting:* Society of Automotive Engineers, Inc.

SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

(412) 776-4841

American Petroleum Institute (API) classification system and oil selection for API Publication No. 1509 can be obtained from your local library, college or technological society, or contact:* American Petroleum Institute

1220 L St.

Washington, DC 20005

(202) 682-8000

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:* Engine Manufacturers Association

Lubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

The following literature can be obtained through any Caterpillar dealer. The literature specific for your engine can be found in the Information Section, Product Support topic in this manual.Oil

Oil and Your Engine SEBD0640Question & Answer Booklet PEDP7122Cat Lithium Grease (MPGL) PEHP0003Cat Special Purpose Grease (SPG) PEHP0017How to Take a Good Oil Sample PEHP6001Cat Engine Oil Spec Sheets PEHP7504Cat Diesel Engine Oil Spec Sheets PEHP7505Cat Fluids Selector PEWP9733Fuel

Diesel Fuels and Your Engine SEBD0717Coolant

Know Your Cooling System SEBD0518Coolant and Your Engine SEBD0970Miscellaneous

3406B Industrial and Marine Service Manual SENR3023Index to Guidelines for Reusable Parts and Salvage Operations SEBF8029Storage Procedure for Caterpillar Products SEHS9031The Caterpillar Engine Technical Manual (Volume I) LEO0002The Caterpillar Engine Technical Manual (Volume II) LEO0003All of the above publications are available through your Caterpillar dealer.Additional Reference Material

ASTM Specs can normally be obtained from your local technological society, library or college or contacting:* American Society for Testing and Materials

1916 Race St.

Philadelphia, PA 19103

(215) 299-5400

Society of Automotive Engineers (SAE) Specs can be found in your SAE handbook or can be obtained from your local library, college or technological society, or contacting:* Society of Automotive Engineers, Inc.

SAE International

400 Commonwealth Drive

Warrendale, PA USA 15096-0001

(412) 776-4841

American Petroleum Institute (API) classification system and oil selection for API Publication No. 1509 can be obtained from your local library, college or technological society, or contact:* American Petroleum Institute

1220 L St.

Washington, DC 20005

(202) 682-8000

Engine Manufacturers Association (EMA) information for lube oil selection can be obtained from your local library, college or technological society, or contact:* Engine Manufacturers Association

Lubricating Oils Data Book

401 N. Michigan Ave. Ste. 2400

Chicago, IL 60611

(312) 644-6610 ext. 3626

Have questions with 107692-1344?

Group cross 107692-1344 ZEXEL

Isuzu

Isuzu

107692-1344

9 400 619 010

8943907965

INJECTION-PUMP ASSEMBLY

6HH1

6HH1