Information injection-pump assembly

ZEXEL

107692-1240

1076921240

Rating:

Cross reference number

ZEXEL

107692-1240

1076921240

Zexel num

Bosch num

Firm num

Name

107692-1240

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407910-3

03*

Selector switch no.

00

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

11

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

1.9

1.87

1.93

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

13.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

102.5

100.9

104.1

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the rack

*

PS407980-224*

V

1.88+-0.

01

PS407980-224*

mm

3.2+-0.0

5

PS407910-303*

V

1.88+-0.

01

PS407910-303*

mm

3.2+-0.0

5

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

9.1+-0.5

Pump speed

r/min

410

410

410

Average injection quantity

mm3/st.

18.5

16.7

20.3

Max. variation between cylinders

%

0

-14

14

Fixing the rack

*

PS407980-224*

V

V1-0.05+

-0.01

PS407980-224*

mm

4.9+-0.0

3

PS407910-303*

V

V1-0.05+

-0.01

PS407910-303*

mm

4.9+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(13.3)

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

102.5

101.5

103.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

PS407980-224*

V

1.88+-0.

01

PS407980-224*

mm

3.2+-0.0

5

PS407910-303*

V

1.88+-0.

01

PS407910-303*

mm

3.2+-0.0

5

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-1.9

Boost pressure

kPa

17.3

16

18.6

Boost pressure

mmHg

130

120

140

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2(R1-0.

35)

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

0000001601

CU407980-224*

*

Actuator advancing type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5

4.95

5.05

Output voltage

V

2.83

2.82

2.84

Adjustment

*

Remarks

Output voltage V1

Output voltage V1

_02

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

1.9

1.87

1.93

Output voltage

V

1.2

1

1.4

Confirmation

*

_03

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

_04

CU407910-303*

*

Actuator advancing type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5

4.95

5.05

Output voltage

V

2.83

2.82

2.84

Adjustment

*

Remarks

Output voltage V1

Output voltage V1

_05

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

1.9

1.87

1.93

Output voltage

V

1.2

1

1.4

Confirmation

*

_06

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

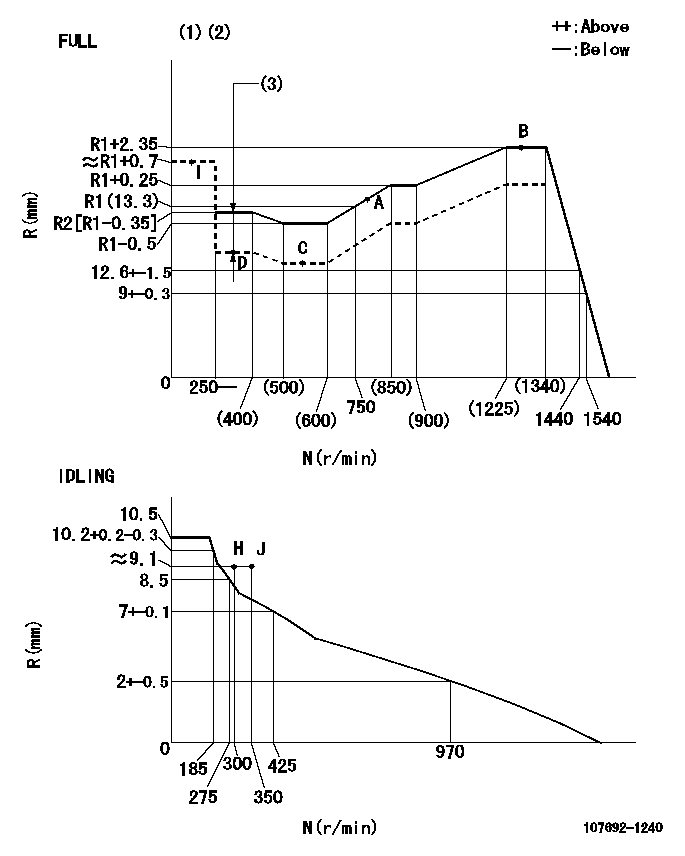

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

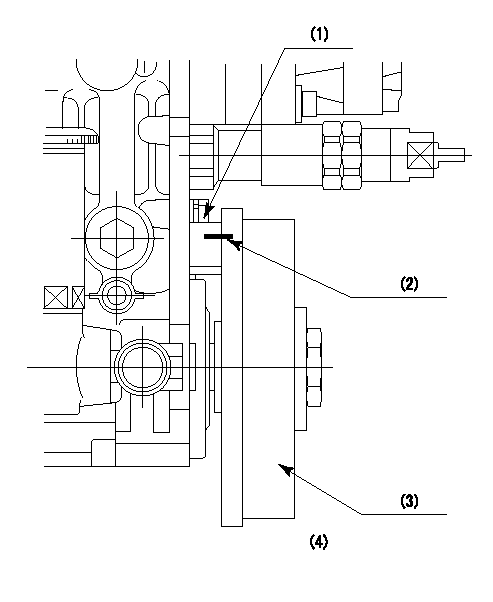

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AB48 BCL=1.9+-0.1mm

----------

----------

T1=AB48 BCL=1.9+-0.1mm

----------

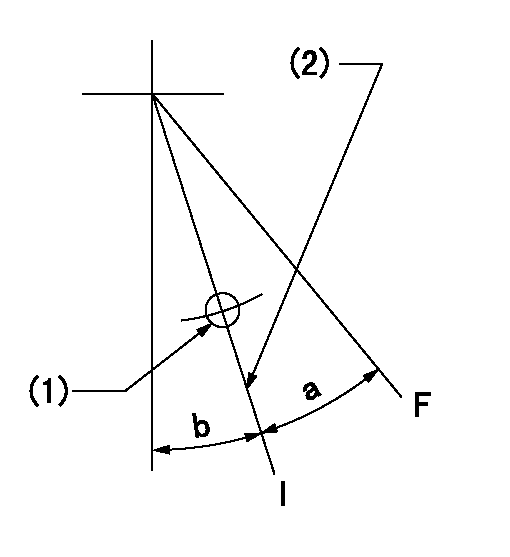

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=40mm

----------

a=32deg+-3deg b=1deg+-5deg

----------

aa=40mm

----------

a=32deg+-3deg b=1deg+-5deg

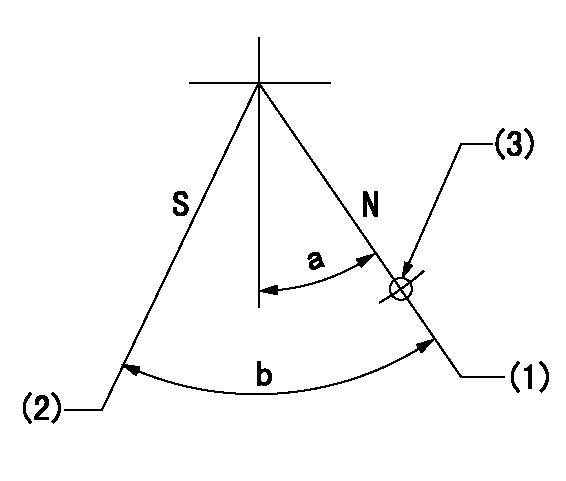

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)-

(2)Set the stopper bolt at speed = aa and rack position = bb and confirm non-injection.

(3)Use the pin above R = cc

----------

aa=0r/min bb=1.5+-0.3mm cc=40mm

----------

a=12deg+-5deg b=44deg+-5deg

----------

aa=0r/min bb=1.5+-0.3mm cc=40mm

----------

a=12deg+-5deg b=44deg+-5deg

0000001301

(1)Pump vertical direction

(2)Position of flywheel's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=22deg bb=1.9+-0.03mm

----------

a=(60deg)

----------

aa=22deg bb=1.9+-0.03mm

----------

a=(60deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

0000001701

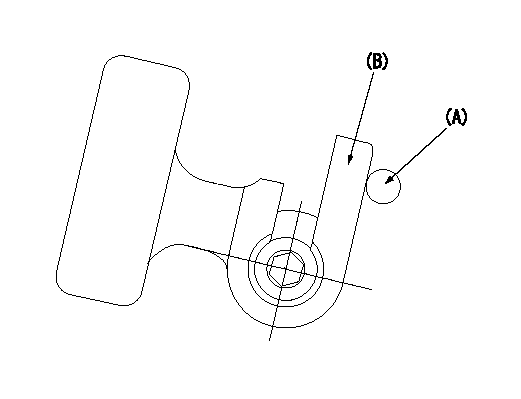

A : Stopper pin

B: Connector

----------

----------

----------

----------

0000001801

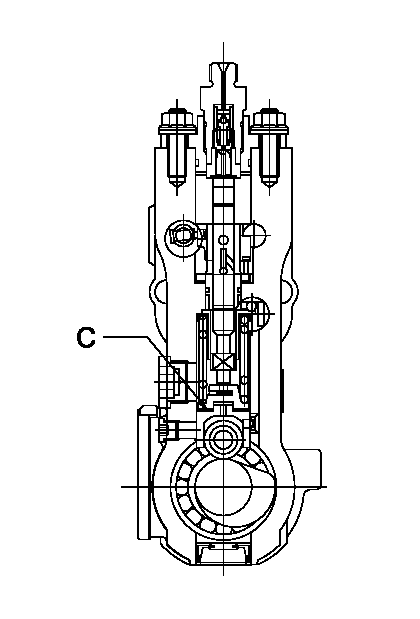

C:Shim

----------

----------

----------

----------

0000001901

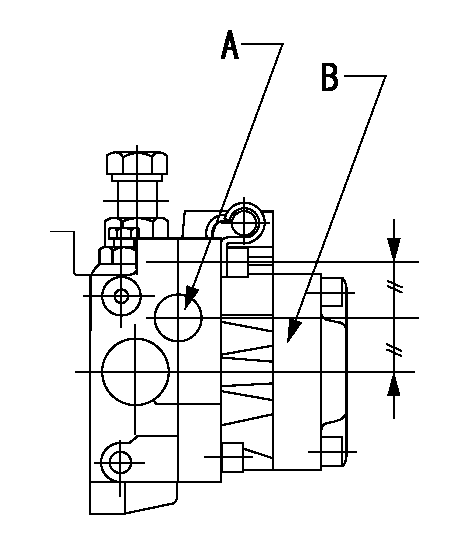

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully clockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the counterclockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1250r/min Ra=R1(13.3)+2.35mm

----------

----------

N1=1250r/min Ra=R1(13.3)+2.35mm

----------

Information:

North America Only:When a problem arises concerning the sale, operation or service of your engine, or the marine vessel OEM, it will normally be handled by the dealer in your area. The service facility nearest you can be located 24 hours-a-day by calling In U.S. and Canada 1 (800) 447-4986.Your satisfaction is a primary concern to Caterpillar and its dealers. To assure your complete satisfaction, we suggest the following steps be followed should you have a problem that has not been handled to your satisfaction. Step One- Discuss your problem with a member of management from the dealership. Step Two- When it appears that your problem cannot be readily resolved at the dealer level without additional assistance, use the above telephone number and ask to talk to a Field Service Coordinator. Regular Monday through Friday business hours are from 8:00 a.m. to 4:30 p.m. Central Standard Time (CST). Step Three If you are still not satisfied, present the engine matter in writing to:Caterpillar Inc.

Manager, Customer Service, Engine Division

Mossville Bldg. A

P.O. Box 600

Mossville, Illinois 61552-0600

When contacting the Manager, Customer Service, please keep in mind that your problem will likely be resolved at the dealership, using their facilities, equipment and personnel. Therefore, it is suggested that you follow the above steps in sequence when experiencing a problem. Outside North America:If a problem arises outside North America and cannot be resolved at the dealer level, contact the appropriate Caterpillar subsidiary office. Mid and South America (except Brazil):Caterpillar Americas Co.

100 NE Adams Street

Peoria, Illinois 61629 U.S.A.

Phone: 309-675-5876

Brazil:Caterpillar Brasil S.A.

04795-Av. Das Nacoes Unidas,

22.540 (S. Amaro)

Mail Address: Caixa Postal, 8239

01.000-Sao Paulo-SP-Brazil

Phone: 247-1011-5919-1100

Cable Address: CATERPILLAR SP. BRAZIL

Telex No.: 391-01122824 & 391-01121496

Europe, Africa, and Middle East:Caterpillar Overseas S.A./Power Systems

YA50 76, Route de Frontenex

P.O. Box 456

1211 Geneva 6

Switzerland

Cable Address: CATOVERSEA

Telex No.: 413323

Phone: (022) 737 4444

Telecopier: (022) 737 4984

Australia and New Zealand:Caterpillar of Australia Ltd.

1 Sharps Road

Private Mail Bag 4

Tullamarine, Victoria 3043

Australia

Telex: AA30240

Cable: CATERPILLAR MELB

Phone: (03) 3399333

Far East (except Japan and Australia):Caterpillar Far East Limited

28th Floor, Sun Hung Kai Centre

30 Harbour Road

G.P.O. Box 3069

Wanchai, Hong Kong

Cable Address: CATFAREAST HKG

Telex No.: HX73305 CFEL

Phone: 5-8326333

Japan:Caterpillar Mitsubishi Ltd.

3700, Tana, Sagamihara-shi

Kanagawa-ken, 229

Japan

Telex No.: 2872-261CM HAJ

Cable Address: CATERBISHICO SAGAMIHARA

Phone: Sagamihara (0427) 62-1121

Manager, Customer Service, Engine Division

Mossville Bldg. A

P.O. Box 600

Mossville, Illinois 61552-0600

When contacting the Manager, Customer Service, please keep in mind that your problem will likely be resolved at the dealership, using their facilities, equipment and personnel. Therefore, it is suggested that you follow the above steps in sequence when experiencing a problem. Outside North America:If a problem arises outside North America and cannot be resolved at the dealer level, contact the appropriate Caterpillar subsidiary office. Mid and South America (except Brazil):Caterpillar Americas Co.

100 NE Adams Street

Peoria, Illinois 61629 U.S.A.

Phone: 309-675-5876

Brazil:Caterpillar Brasil S.A.

04795-Av. Das Nacoes Unidas,

22.540 (S. Amaro)

Mail Address: Caixa Postal, 8239

01.000-Sao Paulo-SP-Brazil

Phone: 247-1011-5919-1100

Cable Address: CATERPILLAR SP. BRAZIL

Telex No.: 391-01122824 & 391-01121496

Europe, Africa, and Middle East:Caterpillar Overseas S.A./Power Systems

YA50 76, Route de Frontenex

P.O. Box 456

1211 Geneva 6

Switzerland

Cable Address: CATOVERSEA

Telex No.: 413323

Phone: (022) 737 4444

Telecopier: (022) 737 4984

Australia and New Zealand:Caterpillar of Australia Ltd.

1 Sharps Road

Private Mail Bag 4

Tullamarine, Victoria 3043

Australia

Telex: AA30240

Cable: CATERPILLAR MELB

Phone: (03) 3399333

Far East (except Japan and Australia):Caterpillar Far East Limited

28th Floor, Sun Hung Kai Centre

30 Harbour Road

G.P.O. Box 3069

Wanchai, Hong Kong

Cable Address: CATFAREAST HKG

Telex No.: HX73305 CFEL

Phone: 5-8326333

Japan:Caterpillar Mitsubishi Ltd.

3700, Tana, Sagamihara-shi

Kanagawa-ken, 229

Japan

Telex No.: 2872-261CM HAJ

Cable Address: CATERBISHICO SAGAMIHARA

Phone: Sagamihara (0427) 62-1121

Have questions with 107692-1240?

Group cross 107692-1240 ZEXEL

Isuzu

107692-1240

INJECTION-PUMP ASSEMBLY