Information injection-pump assembly

BOSCH

9 400 619 614

9400619614

ZEXEL

107691-2160

1076912160

Rating:

Service parts 107691-2160 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

107691-2160

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 619 614

9400619614

ZEXEL

107691-2160

1076912160

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

14

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

10.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77

75.4

78.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

7.5+-0.5

Pump speed

r/min

670

670

670

Average injection quantity

mm3/st.

9

7.5

10.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(10.8)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

77

76

78

Basic

*

Fixing the lever

*

Boost pressure

kPa

48

48

Boost pressure

mmHg

360

360

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.45

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

91.4

87.4

95.4

Fixing the lever

*

Boost pressure

kPa

48

48

Boost pressure

mmHg

360

360

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

Injection quantity adjustment_05

Adjusting point

C

Rack position

R2(R1-0.

9)

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

37.1

33.1

41.1

Fixing the lever

*

Boost pressure

kPa

48

48

Boost pressure

mmHg

360

360

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

Injection quantity adjustment_06

Adjusting point

D

Rack position

R3-0.9

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

21

17

25

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

R3-0.9

Boost pressure

kPa

15.3

14

16.6

Boost pressure

mmHg

115

105

125

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

R3(R1-0.

9)

Boost pressure

kPa

34.7

34.7

34.7

Boost pressure

mmHg

260

260

260

Timer adjustment

Pump speed

r/min

1070--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1020

Advance angle

deg.

0

-0.5

0

Timer adjustment_03

Pump speed

r/min

1080

Advance angle

deg.

-1.3

-1.8

-0.8

Remarks

Finish

Finish

0000001601

CU407980-224*

*

Actuator retarding type

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

_03

CU407980-224*

*

Supply voltage

V

24

23.5

24.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=G34 BCL=0.9+-0.1mm

----------

----------

T1=G34 BCL=0.9+-0.1mm

----------

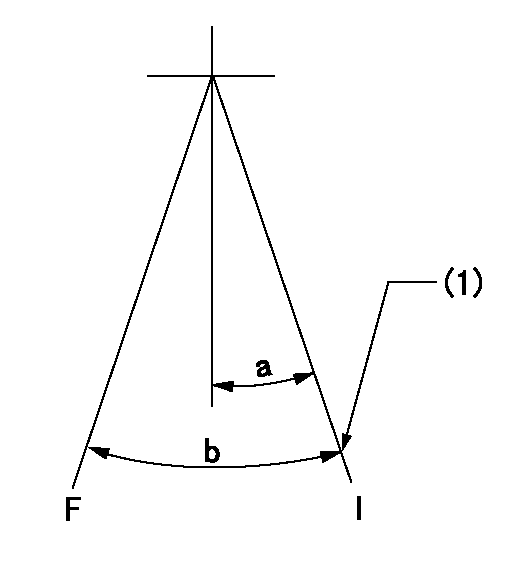

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=24deg+-5deg b=40deg+-3deg

----------

----------

a=24deg+-5deg b=40deg+-3deg

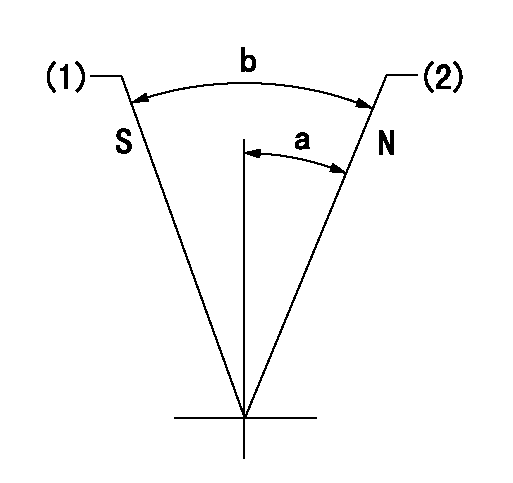

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at speed = aa and rack position = bb and confirm non-injection.

(2)Normal

----------

aa=1670r/min bb=4.5-0.5mm

----------

a=15deg+-5deg b=38deg+-5deg

----------

aa=1670r/min bb=4.5-0.5mm

----------

a=15deg+-5deg b=38deg+-5deg

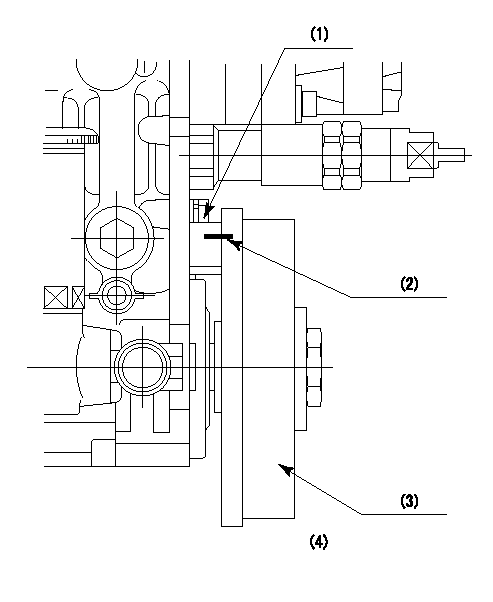

0000001301

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=6deg bb=5.6+-0.03mm

----------

a=(7deg)

----------

aa=6deg bb=5.6+-0.03mm

----------

a=(7deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

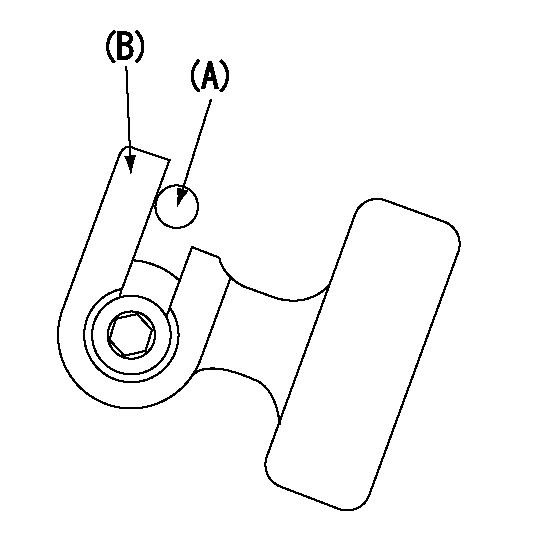

0000001701

A : Stopper pin

B: Connector

----------

----------

----------

----------

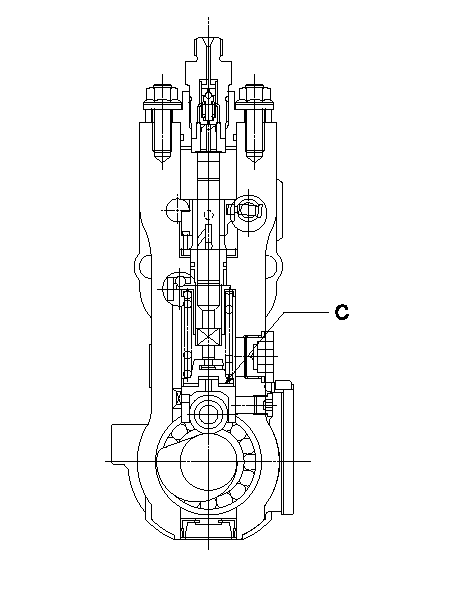

0000001801

C:Shim

----------

----------

----------

----------

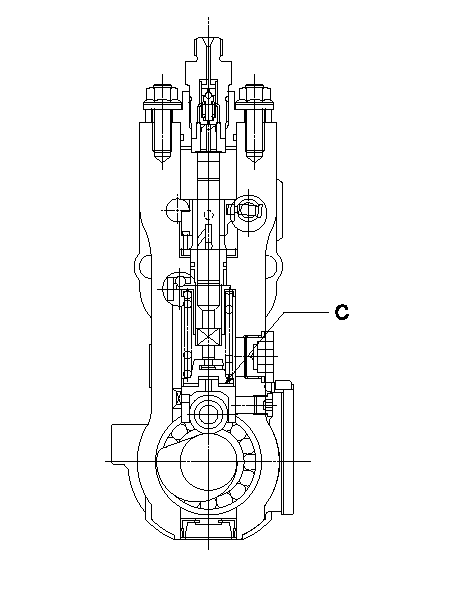

0000001901

C:Shim

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1500r/min Ra=R1(10.8)+1.45mm

----------

----------

N1=1500r/min Ra=R1(10.8)+1.45mm

----------

Information:

Table 4

Cat Specification for Neat (B100) Biodiesel Blending Fuel

Property Test Method, United States Test Method, International Units Limits, B100 Blending Fuel

Density at 15°C “ASTM D1298” “ISO 3675” g/cm3 0.86-0.90

Viscosity at 40°C “ASTM D445” “ISO 3104” mm2/s (cSt) 1.9-6.0

Flash Point “ASTM D93” “ISO 3679” °C 93 minimum

Pour Point - - - 6 °C (10 °F) minimum below ambient temperature

- Summer “ASTM D97” “ISO 3016” °C

- Winter

Cloud Point “ASTM D2500” °C Report

Sulfur Content(1) “ASTM D5453” “ISO 20846” “ISO 20884” percent weight 0.0015(2) maximum

Distillation - - - -

T90 “ASTM D86” “ISO 3924” °C 360

Cetane Number “ASTM D613” “ISO 5165” % evaporation 45 minimum

Sulfated Ash “ASTM D874” “ISO 3987” or "ISO 6245" percent weight 0.02 maximum

Water and Sediment “ASTM D2709” “ISO 12937” percent volume 0.05 maximum

Water "ASTM D1796" "EN ISO 12937" % m/m -

Copper Corrosion, 3 hours at 50oC “ASTM D130” “ISO 2160” - No. 1

Oxidation Stability “EN 14112” or "EN 15751" “EN 14112” or "EN 15751" hours 3 minimum

Ramsbottom Carbon Residue on 10% bottoms "ASTM D524" “ISO 10370” %-m/m 0.30 maximum

Carbon Residue, Conradson (CCR) “ASTM D4530” - percent weight 0.05 maximum

Esterification "ASTM D 7806" or "ASTM D 7371" “EN 14103” percent volume 97.5 minimum

Total Acid Number “ASTM D664” “EN 14104” mg KOH/g 0.5 maximum

Methanol Content “EN 14110” “EN 14110” percent weight 0.2 maximum

Monoglycerides “ASTM D6584” “EN 14105” percent weight 0.8 maximum

Diglycerides “ASTM D6584” “EN 14105” percent weight 0.2 maximum

Triglycerides “ASTM D6584” “EN 14105” percent weight 0.2 maximum

Free Glycerin “ASTM D6584” “EN 14105” percent weight 0.02 maximum

Total Glycerin “ASTM D6584” “EN 14105” percent weight 0.240 maximum

Phosphorus Content “ASTM D4951” “EN 14107” percent weight 0.001 maximum

Calcium plus Magnesium “EN 14538” “EN 14538” ppm 5 maximum

Sodium plus Potassium “EN 14538” “EN 14538” ppm 5 maximum

Cold Soak Filterability “ASTM D7501” – seconds 360 maximum

Cleanliness “ASTM D7619” “ISO 4406” – (3)

Total contamination "EN 12662" "EN 12662" mg/kg 24 maximum

Appearance "ASTM D4176" - - Clear and Bright

(1) Methods for testing S are based on the sulfur content in diesel fuel used for blending. Consult with the fuel supplier and ensure the correct method has been used

(2) Sulfur level must be per local regulations. Higher S levels may be used where allowed.

(3) Recommended cleanliness level for fuel as dispensed into the engine fuel tank is ISO 18/16/13 or cleaner per the test methods listed. Refer to the contamination control Chapter for more details.Note: Fuels that meet the most current revision level of "ASTM D6751" or "EN 14214" may be used for blending with an acceptable distillate fuel. The conditions, recommendations, and limits that are noted in this Biodiesel section apply.Referenced Documents

Refer to the “Reference Material - Fuel” section of this Special Publication for the reference material for the information in this section.