Information injection-pump assembly

ZEXEL

107492-2090

1074922090

Rating:

Cross reference number

ZEXEL

107492-2090

1074922090

Zexel num

Bosch num

Firm num

Name

107492-2090

INJECTION-PUMP ASSEMBLY

14CF TICS MD-TI4 TICS

14CF TICS MD-TI4 TICS

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0520

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407910-3

03*

Selector switch no.

02

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

01

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.8

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

101

99.4

102.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

5

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

7.5+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

16

14.5

17.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

PS407980-224*

V

V1+0.05+

-0.01

PS407980-224*

mm

5.5+-0.0

3

PS407910-303*

V

V1+0.05+

-0.01

PS407910-303*

mm

5.5+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Remarks

Refer to items regarding the pre-stroke actuator

Refer to items regarding the pre-stroke actuator

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.8)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

101

100

102

Fixing the lever

*

Boost pressure

kPa

42

42

Boost pressure

mmHg

315

315

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

5

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.55

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

99

95

103

Fixing the lever

*

Boost pressure

kPa

42

42

Boost pressure

mmHg

315

315

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

5

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

5

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-0.75

Boost pressure

kPa

22

20.7

23.3

Boost pressure

mmHg

165

155

175

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2[R1-0.

95]

Boost pressure

kPa

28.7

28.7

28.7

Boost pressure

mmHg

215

215

215

0000001601

CU407980-224*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_03

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

_04

CU407910-303*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_05

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

Remarks

Output voltage V1

Output voltage V1

_06

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

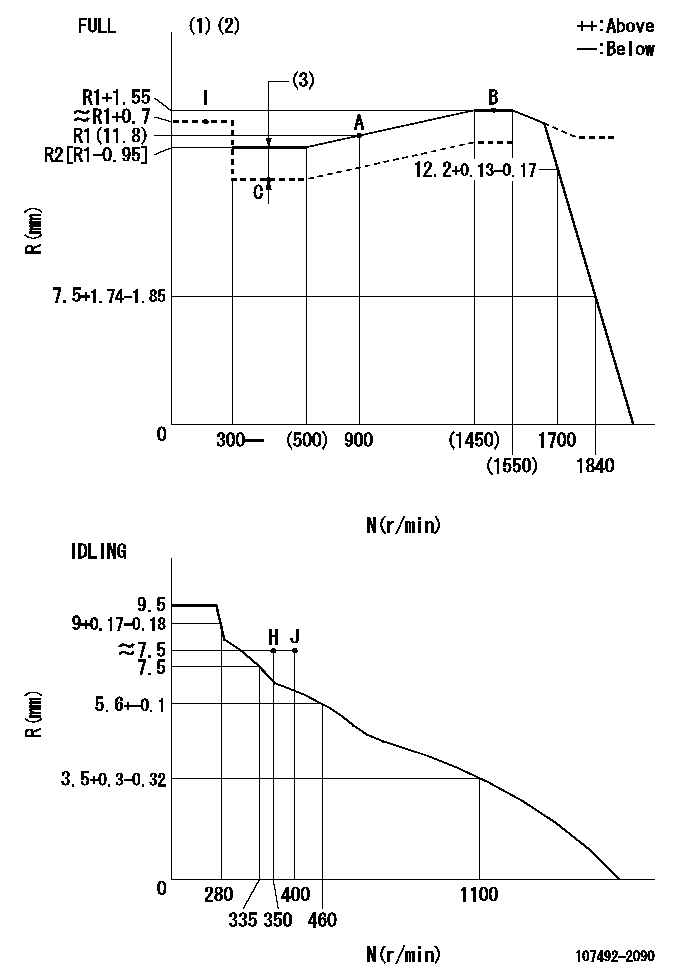

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=K79 BCL=0.75+-0.1mm

----------

----------

T1=K79 BCL=0.75+-0.1mm

----------

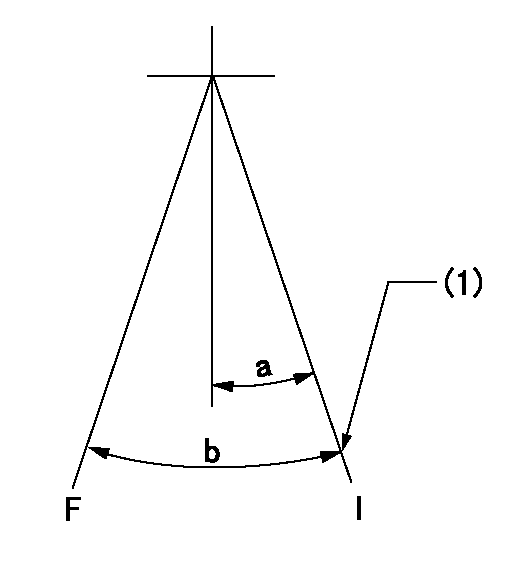

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=25deg+-5deg b=(41deg)+-3deg

----------

----------

a=25deg+-5deg b=(41deg)+-3deg

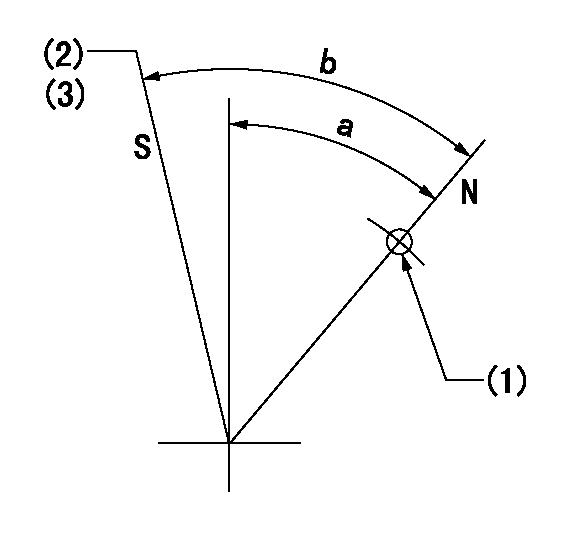

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

(2)Set the stopper screw so that speed = bb and the rack position = cc and confirm non-injection.

(3)After setting the stopper bolt, confirm non-injection at speed dd.

----------

aa=40mm bb=1450r/min cc=1-0.5mm dd=350r/min

----------

a=36.5deg+-5deg b=(45deg)+-5deg

----------

aa=40mm bb=1450r/min cc=1-0.5mm dd=350r/min

----------

a=36.5deg+-5deg b=(45deg)+-5deg

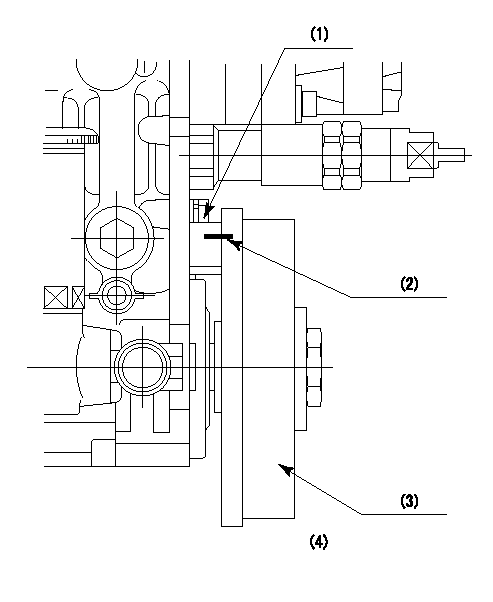

0000001301

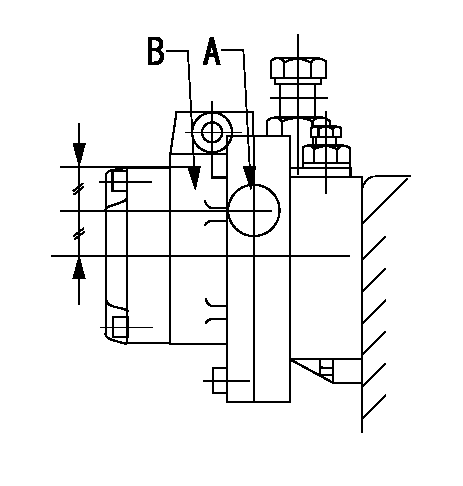

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=7deg bb=5.6+-0.03mm

----------

a=(130deg)

----------

aa=7deg bb=5.6+-0.03mm

----------

a=(130deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

0000001701

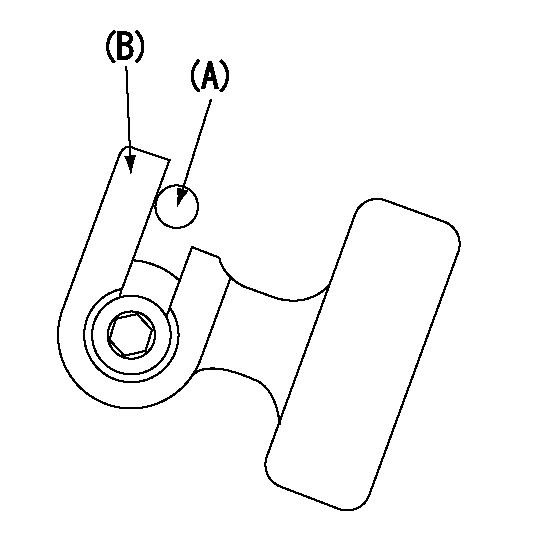

A : Stopper pin

B: Connector

----------

----------

----------

----------

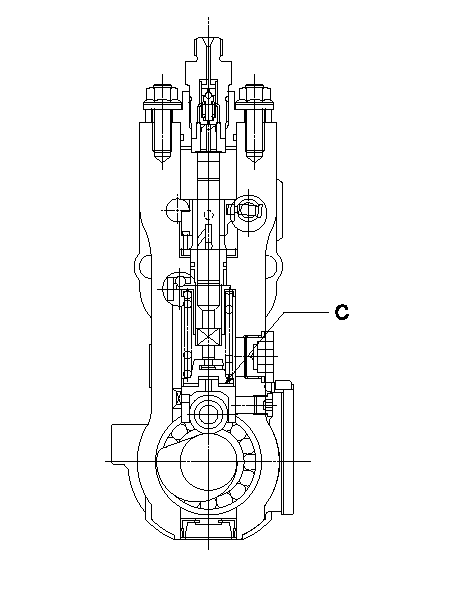

0000001801

C:Shim

----------

----------

----------

----------

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1500r/min Ra=R1(11.8)+1.55mm

----------

----------

N1=1500r/min Ra=R1(11.8)+1.55mm

----------

Information:

Misfiring And Running Rough

See MISFIRING AND RUNNING ROUGH.Problem With Vehicle Or Vehicle Operation

See PROBLEM WITH VEHICLE OR VEHICLE OPERATION.Low Engine RPM

Governor Linkage...Disconnect the governor linkage at the lever on the governor. Move the governor lever by hand until the linkage inside the governor is against the high idle stop. With the accelerator pedal all the way down, adjust the linkage so the inside linkage is against the high idle stop. Some trucks are equipped with linkage which has spring force and some are equipped with a governor lever of the break over type. On engines with either of these, adjust the governor linkage .250 in. (6,35 mm) longer than necessary for the inside linkage to be against the high idle stop, this will keep tension on the spring at all times. For trucks with tilt cabs, do not make this check with the cab tilted.Governor High Idle Adjustment...If the governor linkage moves the governor lever to the fully open position, check the high idle rpm with a good tachometer. *Not Enough Air

Inlet Restriction...An inlet restriction will cause low power and too much smoke when under load. Check for a restriction with a water manometer or a vacuum gauge (which measures in inches of water). Connect the gauge to the engine air inlet between the air cleaner and the engine. With gauge installed, run engine at high idle rpm and check the restriction. Maximum restriction of the air inlet is 25 inches (635 mm) of water. If the indication is higher than the maximum permissible restriction, clean or install a new filter element and check the restriction again. If the indication is still too high, there must be a restriction in the inlet piping.Exhaust Restriction...Make a visual inspection of the exhaust system and look for damage to piping or muffler. If no damage is found, you can also check the system by removing the exhaust pipes from the exhaust manifolds. With the exhaust pipes removed, start and run the engine to see if the problem is corrected.Exhaust restriction can be checked with a manometer.Low Quality Fuel

Water in Fuel...Drain a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, drain tank. Install a new fuel filter and fill the fuel tank with clean fuel. "Prime" (remove the air and/or low quality fuel from the fuel system) the fuel system. See PRIMING FUEL SYSTEM.Fuel With Low Specific Gravity...Remove a small amount of fuel from the tank and measure the API gravity with a fuel hydrometer. Caterpillar engines are rated on fuel having 35 API gravity at 60°F (16°C). If the API gravity of the fuel used is more than 40, the result will be a reduction in power.Fuel System Problems

Low Fuel Pressure...Remove the cap from the tee at the fuel filter. Connect a pressure gauge to the tee. Run the engine under load and check the pressure. If the pressure is lower than 13 psi (0,9 kg/cm2), install a

See MISFIRING AND RUNNING ROUGH.Problem With Vehicle Or Vehicle Operation

See PROBLEM WITH VEHICLE OR VEHICLE OPERATION.Low Engine RPM

Governor Linkage...Disconnect the governor linkage at the lever on the governor. Move the governor lever by hand until the linkage inside the governor is against the high idle stop. With the accelerator pedal all the way down, adjust the linkage so the inside linkage is against the high idle stop. Some trucks are equipped with linkage which has spring force and some are equipped with a governor lever of the break over type. On engines with either of these, adjust the governor linkage .250 in. (6,35 mm) longer than necessary for the inside linkage to be against the high idle stop, this will keep tension on the spring at all times. For trucks with tilt cabs, do not make this check with the cab tilted.Governor High Idle Adjustment...If the governor linkage moves the governor lever to the fully open position, check the high idle rpm with a good tachometer. *Not Enough Air

Inlet Restriction...An inlet restriction will cause low power and too much smoke when under load. Check for a restriction with a water manometer or a vacuum gauge (which measures in inches of water). Connect the gauge to the engine air inlet between the air cleaner and the engine. With gauge installed, run engine at high idle rpm and check the restriction. Maximum restriction of the air inlet is 25 inches (635 mm) of water. If the indication is higher than the maximum permissible restriction, clean or install a new filter element and check the restriction again. If the indication is still too high, there must be a restriction in the inlet piping.Exhaust Restriction...Make a visual inspection of the exhaust system and look for damage to piping or muffler. If no damage is found, you can also check the system by removing the exhaust pipes from the exhaust manifolds. With the exhaust pipes removed, start and run the engine to see if the problem is corrected.Exhaust restriction can be checked with a manometer.Low Quality Fuel

Water in Fuel...Drain a small amount of fuel from the tank and check for water in the fuel. If there is water in the fuel, drain tank. Install a new fuel filter and fill the fuel tank with clean fuel. "Prime" (remove the air and/or low quality fuel from the fuel system) the fuel system. See PRIMING FUEL SYSTEM.Fuel With Low Specific Gravity...Remove a small amount of fuel from the tank and measure the API gravity with a fuel hydrometer. Caterpillar engines are rated on fuel having 35 API gravity at 60°F (16°C). If the API gravity of the fuel used is more than 40, the result will be a reduction in power.Fuel System Problems

Low Fuel Pressure...Remove the cap from the tee at the fuel filter. Connect a pressure gauge to the tee. Run the engine under load and check the pressure. If the pressure is lower than 13 psi (0,9 kg/cm2), install a

Have questions with 107492-2090?

Group cross 107492-2090 ZEXEL

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

Mitsubishi

107492-2090

INJECTION-PUMP ASSEMBLY