Information injection-pump assembly

BOSCH

F 019 Z10 039

f019z10039

ZEXEL

107492-2061

1074922061

Rating:

Service parts 107492-2061 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

107492-2061

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 039

f019z10039

ZEXEL

107492-2061

1074922061

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8240

Nozzle

105780-0110

Nozzle holder

105780-2170

Opening pressure

MPa

20.6

Opening pressure

kgf/cm2

210

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0520

Overflow valve opening pressure

kPa

255

255

255

Overflow valve opening pressure

kgf/cm2

2.6

2.6

2.6

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407910-3

03*

Selector switch no.

02

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

01

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

93

91.4

94.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.4+-0.5

Pump speed

r/min

625

625

625

Average injection quantity

mm3/st.

10

8.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

93

92

94

Basic

*

Fixing the lever

*

Boost pressure

kPa

44

44

Boost pressure

mmHg

330

330

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.55

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

100.5

96.5

104.5

Fixing the lever

*

Boost pressure

kPa

44

44

Boost pressure

mmHg

330

330

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-0.9

Boost pressure

kPa

21.3

20

22.6

Boost pressure

mmHg

160

150

170

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2[R1-0.

85]

Boost pressure

kPa

30.7

30.7

30.7

Boost pressure

mmHg

230

230

230

0000001601

CU407980-224*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

_03

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

_04

CU407910-303*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_05

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

_06

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

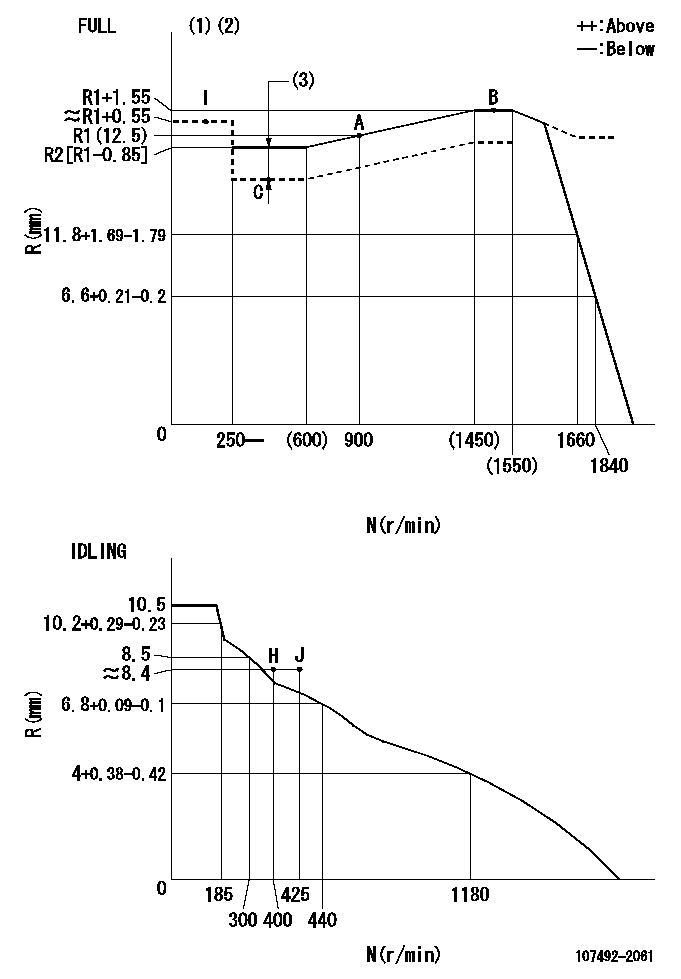

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=J47 BCL=0.9+-0.1mm

----------

----------

T1=J47 BCL=0.9+-0.1mm

----------

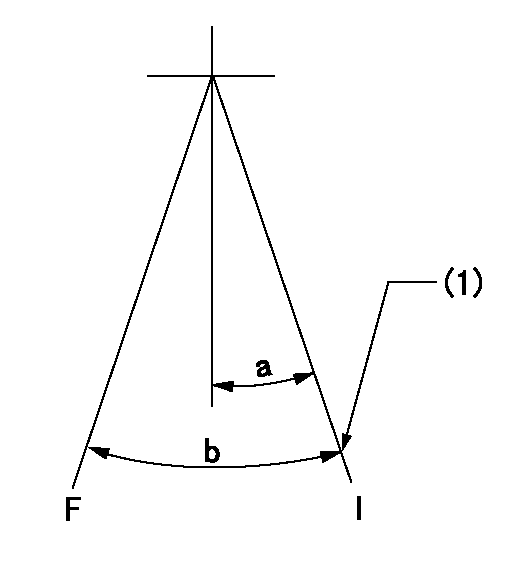

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=20deg+-5deg b=(35.5deg)+-3deg

----------

----------

a=20deg+-5deg b=(35.5deg)+-3deg

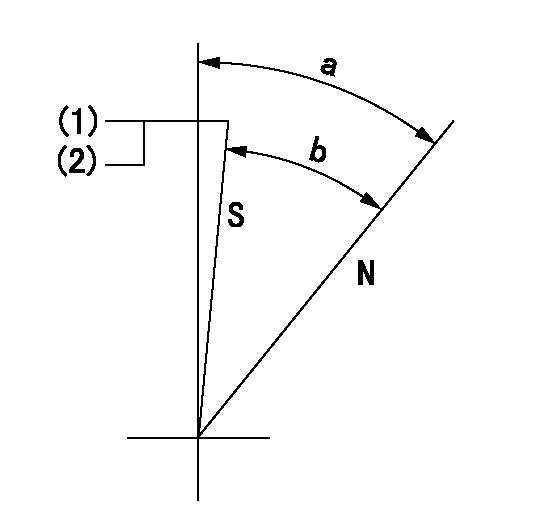

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At pump speed aa and rack position bb, set the stopper bolt. Confirm non-injection.

(2)After setting stopper bolt, confirm non-injection at pump speed cc.

----------

aa=1450r/min bb=6.2-0.5mm cc=300r/min

----------

a=36.5deg+-5deg b=(33deg)+-5deg

----------

aa=1450r/min bb=6.2-0.5mm cc=300r/min

----------

a=36.5deg+-5deg b=(33deg)+-5deg

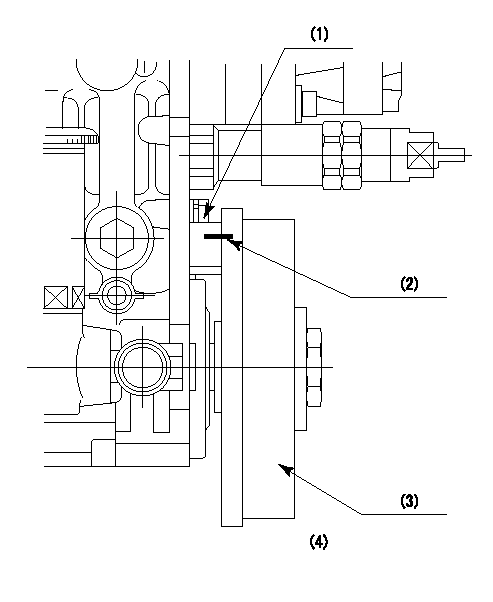

0000001301

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=7deg bb=5.6+-0.03mm

----------

a=(130deg)

----------

aa=7deg bb=5.6+-0.03mm

----------

a=(130deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

0000001701

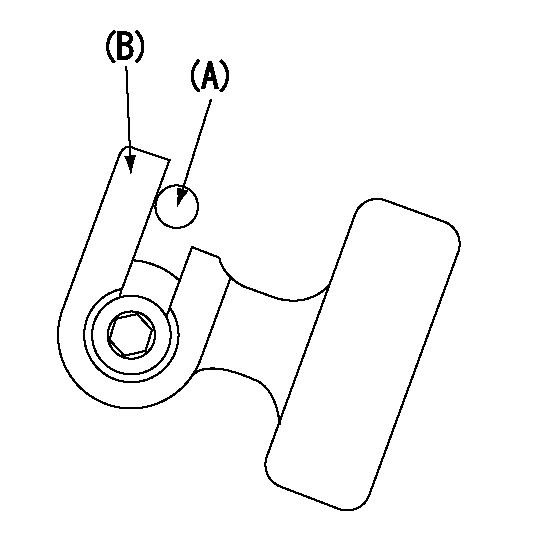

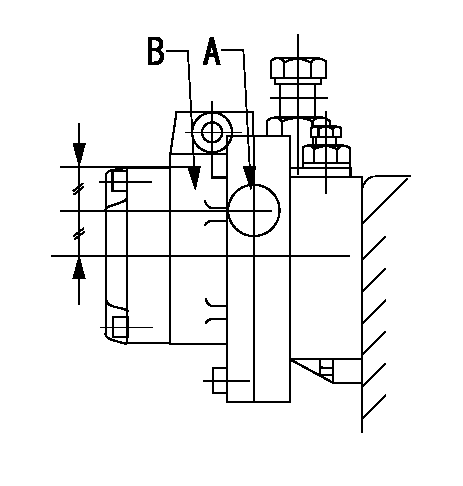

A : Stopper pin

B: Connector

----------

----------

----------

----------

0000001801

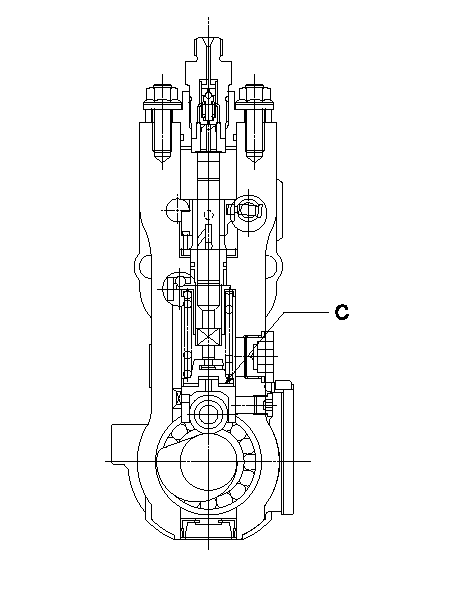

C:Shim

----------

----------

----------

----------

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1500r/min Ra=R1(12.5)+1.55mm

----------

----------

N1=1500r/min Ra=R1(12.5)+1.55mm

----------

Information:

The lubrication system consists of a sump (oil pan), oil pump, oil cooler and oil filter. The engine contains an oil manifold and oil passages to direct lubricant to the various components.The oil pump draws lubricant from the sump and forces it through the oil cooler, oil filter, and then into the oil manifold. Oil flows through connecting passages to lubricate the engine components. A regulating valve in the pump body controls the maximum pressure of the oil from the pump. When the engine is started, the lubricating oil in the oil pan is cool (thick). This cool viscous oil does not flow immediately through the oil cooler and oil filter. This cool oil forces bypass valves, in the oil cooler and oil filter base, to open allowing an unrestricted oil to flow through the engine.As oil temperature increases, oil viscosity and pressure decrease and the oil filter bypass valve closes. Now, only filtered oil is delivered to the engine components. Oil temperature continues to increase and the oil cooler bypass valve closes. Oil now flows through the oil cooler and oil filter before reaching the engine components.A contaminated or restricted oil filter element will not prevent lubricating oil from being delivered to the engine components. The oil filter bypass valve will open, allowing oil to bypass the element.An oil manifold, cast into the cylinder block, directs lubricant to the main bearings, valve rocker arm shafts, camshaft journals, and the camshaft idler (drive) gears.Oil spray orifices in the cylinder block spray oil on the underside of the pistons. This cools the pistons and provides lubricant for the piston pins, cylinder walls and piston rings.The connecting rod bearings receive oil through drilled passages in the crankshaft between the main bearing journals and connecting rod journals.When the engine is warm and running at rated speed, the oil pressure gauge should register in the "operating range". A lower pressure reading is normal at idling speeds.Many engines are equipped with an auxiliary or remote mounted bypass filter system. This system must be connected so part of the oil continuously circulates through the bypass filter, from the crankcase lubricating oil pump. An orifice on the outlet or clean side of the filter restricts the flow of oil through the bypass filter so full oil pressure is available to all parts of the engine. Filtered oil from the bypass filter is returned to the crankcase sump. Because of the additional oil capacity, extended change intervals can be established. See Lubrication Chart. The Bypass filter should never be used in place of the factory installed full flow filter.