Information injection-pump assembly

BOSCH

F 019 Z10 070

f019z10070

ZEXEL

107492-2041

1074922041

Rating:

Service parts 107492-2041 INJECTION-PUMP ASSEMBLY:

1.

_

5.

AUTOM. ADVANCE MECHANIS

6.

COUPLING PLATE

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

107492-2041

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 070

f019z10070

ZEXEL

107492-2041

1074922041

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8240

Nozzle

105780-0110

Nozzle holder

105780-2170

Opening pressure

MPa

20.6

Opening pressure

kgf/cm2

210

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8420

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

PS/ACT control unit part no.

407910-3

03*

Selector switch no.

02

PS/ACT control unit part no.

407980-2

24*

Digi switch no.

01

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-3-4-2

Pre-stroke

mm

5.6

5.57

5.63

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-3 deg. 90 89.75 90.25

Cal 1-3 deg. 90 89.75 90.25

Difference between angles 2

Cal 1-4 deg. 180 179.75 180.25

Cal 1-4 deg. 180 179.75 180.25

Difference between angles 3

Cyl.1-2 deg. 270 269.75 270.25

Cyl.1-2 deg. 270 269.75 270.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.5

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

93

91.4

94.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

8.4+-0.5

Pump speed

r/min

625

625

625

Average injection quantity

mm3/st.

10

8.5

11.5

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.5)

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

93

92

94

Basic

*

Fixing the lever

*

Boost pressure

kPa

44

44

Boost pressure

mmHg

330

330

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+1.55

Pump speed

r/min

1500

1500

1500

Average injection quantity

mm3/st.

100.5

96.5

104.5

Fixing the lever

*

Boost pressure

kPa

44

44

Boost pressure

mmHg

330

330

PS407980-224*

V

2.25+-0.

01

PS407980-224*

mm

3.6+-0.0

3

PS407910-303*

V

2.25+-0.

01

PS407910-303*

mm

3.6+-0.0

3

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

R2-0.9

Boost pressure

kPa

21.3

20

22.6

Boost pressure

mmHg

160

150

170

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

R2(R1-0.

85)

Boost pressure

kPa

30.7

30.7

30.7

Boost pressure

mmHg

230

230

230

0000001601

CU407980-224*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_02

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

_03

CU407980-224*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

_04

CU407910-303*

*

Actuator retarding type

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

2.5

2.45

2.55

Output voltage

V

2.83

2.82

2.84

Adjustment

*

_05

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Pre-stroke

mm

5.6

5.57

5.63

Output voltage

V

1.2

1

1.4

Confirmation

*

_06

CU407910-303*

*

Supply voltage

V

12

11.5

12.5

Ambient temperature

degC

23

18

28

Output voltage

V

3.05

3.05

Confirmation of operating range

*

Test data Ex:

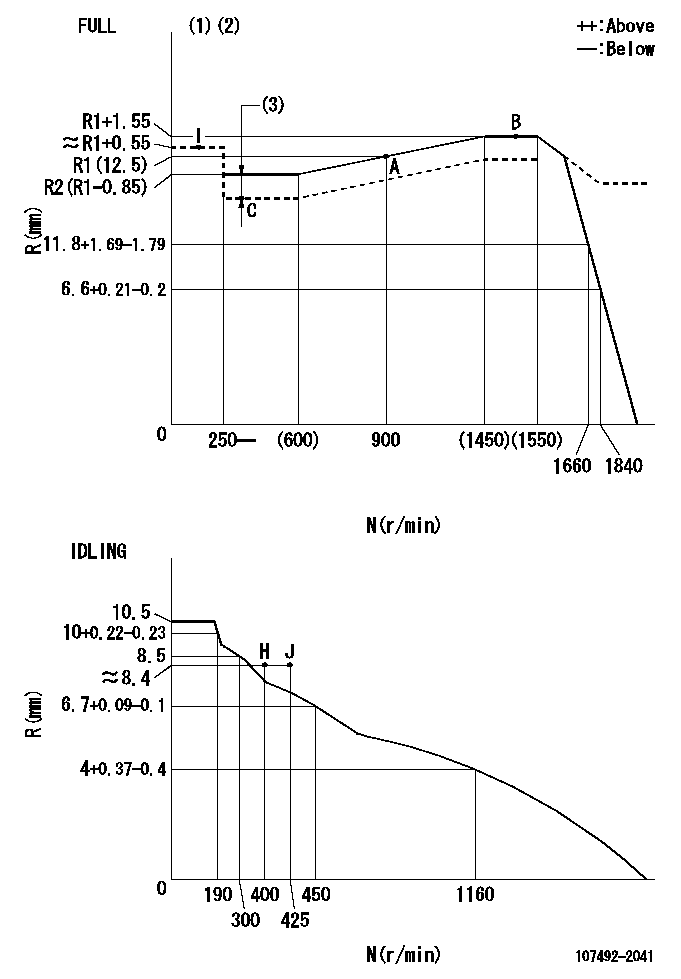

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=J47 BCL=0.9+-0.1mm

----------

----------

T1=J47 BCL=0.9+-0.1mm

----------

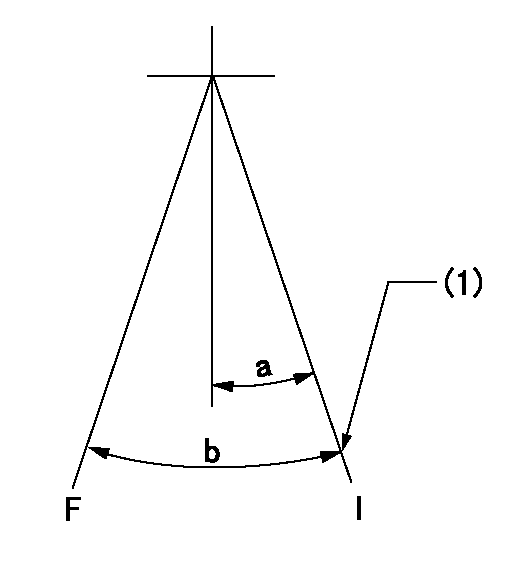

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=20deg+-5deg b=35.5deg+-3deg

----------

----------

a=20deg+-5deg b=35.5deg+-3deg

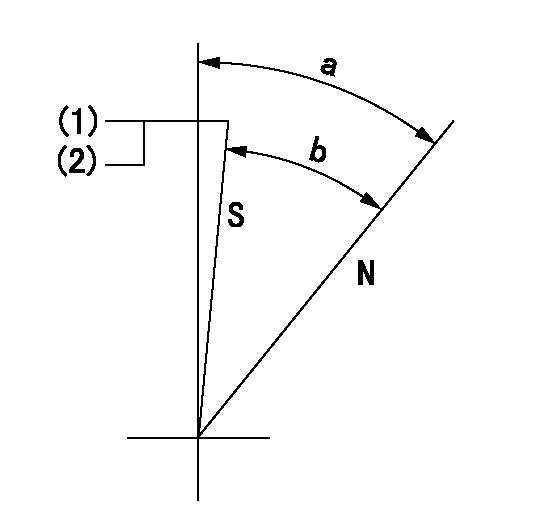

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Set the stopper bolt at speed = aa and rack position = bb and confirm non-injection.

(2)After setting the stopper bolt, confirm non-injection at speed cc.

----------

aa=1450r/min bb=6.2-0.5mm cc=300r/min

----------

a=36.5deg+-5deg b=(33deg)+-5deg

----------

aa=1450r/min bb=6.2-0.5mm cc=300r/min

----------

a=36.5deg+-5deg b=(33deg)+-5deg

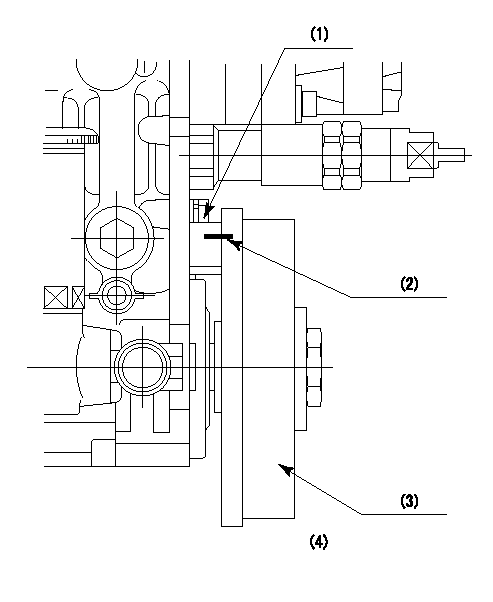

0000001301

(1)Pump vertical direction

(2)Position of gear mark '3' at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)Pre-stroke: bb

----------

aa=7deg bb=5.6+-0.03mm

----------

a=(130deg)

----------

aa=7deg bb=5.6+-0.03mm

----------

a=(130deg)

0000001401

(1)Pointer

(2)Injection timing aligning mark

(3)Fly weight

(4)The actual shape and direction may be different from this illustration.

Operation sequence

1. Turn the prestroke actuator OFF.

2. Turn the camshaft as far as the No.1 cylinder's beginning of injection position.

3. Check that the pointer alignment mark of the injection pump and the alignment mark of the flywheel are matching.

4. If they are not matching, erase the alignment mark on the flywheel side, and stamp an alignment mark on the flywheel position that matches with the pointer side alignment mark.

5. Check again that the coupling's key groove position is in the No.1 cylinder's beginning of injection position.

----------

----------

----------

----------

0000001701

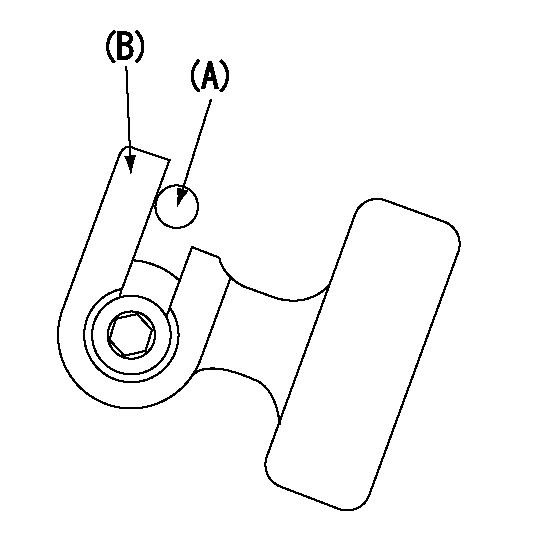

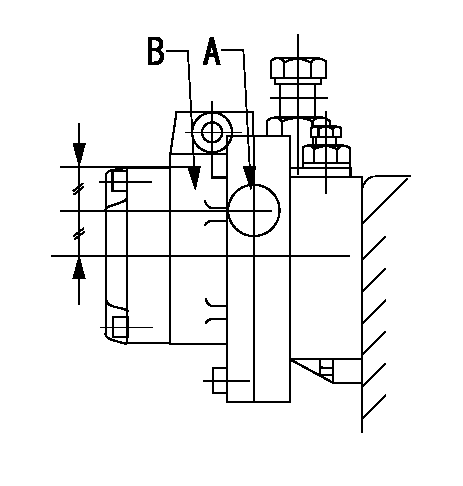

A : Stopper pin

B: Connector

----------

----------

----------

----------

0000001801

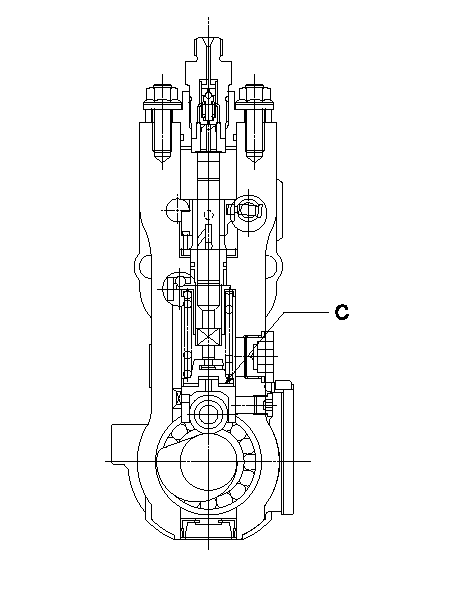

C:Shim

----------

----------

----------

----------

0000001901

A:Sealing position

B:Pre-stroke actuator

1. When installing the pre-stroke actuator on the pump, first tighten the installation bolts loosely, then move the actuator fully counterclockwise (viewed from the drive side).

Temporary tightening torque: 1 - 1.5 N.m (0.1 - 0.15 kgf.m)

2. Move the actuator in the clockwise direction when viewed from the drive side, and adjust so that it becomes the adjustment point of the adjustment value. Then tighten it.

Tightening torque: 7^9 N.m (0.7^0.9 kgf.m)

3. After prestroke actuator installation adjustment, simultaneously stamp both the actuator side and housing side.

----------

----------

----------

----------

0000002201 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=1450r/min Ra=R1(12.5)+1.55mm

----------

----------

N1=1450r/min Ra=R1(12.5)+1.55mm

----------

Information:

The 1674 Diesel Truck Engine is a 638 cu. in (10,5 ltr.) displacement, 4 stroke cycle, 6 cylinder turbocharged and aftercooled engine. This dual overhead cam engine with a 4 valve per cylinder design is made especially for highway trucks hauling big payloads. Serviceability is featured by spin-on throw away fuel filters, easy valve adjustment, replaceable cylinder liners and valve seats, and piston and rod removal from the top.Individual injection pumps, one for each cylinder, meter and pump fuel under high pressure to an injection valve and a precombustion chamber for each cylinder. An automatic variable timing device advances or retards fuel injection and is regulated by engine speed. The faster the engine turns the earlier the injection must take place before piston top center on the compression stroke.A hydro-mechanical governor controls the fuel injection pump out-put to maintain the engine RPM selected by the operator. A speed limiting device, in the governor, limits engine speed until engine oil pressure builds up.Inlet air, filtered by an air cleaner, is compressed by a turbocharger before entering the engine cylinders. The turbocharger is driven by the engine exhaust.There are four in-head valves (two inlet and two exhaust) for each cylinder. Two overhead camshafts, and forked rocker arm assemblies, are located in a housing on top of the cylinder head. The forked rocker arm assemblies act as a direct mechanical link between the lobes on the camshafts and the valve stems. The timing gears are located at the rear of the engine.Coolant for the engine is used to cool the engine lubricating oil. A full-flow temperature regulator, in the cylinder head at the front of the engine, provides for quick engine warm-up, and allows free circulation of coolant after operating temperature has been reached.Lubrication for the engine is supplied by a gear-type pump. The pump provides full pressure lubrication to the engine internal and external parts.The lubricating oil is both cooled and filtered. By-pass valves in the oil cooler assembly provide unrestricted flow of lubrication oil to the engine parts when oil viscosity is high or, if either the oil cooler or the oil filter element should become clogged.The starting system is direct electric and uses a 24 or 12 volt starting motor.Efficiency of emission controls and engine performance depends on adherence to proper operation and maintenance recommendations, and use of recommended fuels and lubrication oils. Major adjustments and repair should be entrusted to your authorized dealer. Follow the recommended maintenance schedule with special emphasis on fuel injection nozzles, air cleaner, fuel-air ratio control and high and low idle adjustment. Fuel-air ratio control and the high and low idle adjustments should be made by an authorized dealer.