Information injection-pump assembly

ZEXEL

106991-1042

1069911042

ISUZU

1156022252

1156022252

Rating:

Service parts 106991-1042 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-204-1

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106991-1042

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106991-1042

1069911042

ISUZU

1156022252

1156022252

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-4020

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-4020

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-9-8-

5-2-11-1

0-3-6-7-

Pre-stroke

mm

4.2

4.17

4.23

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 15 14.75 15.25

Cal 1-4 deg. 15 14.75 15.25

Difference between angles 2

Cal 1-9 deg. 60 59.75 60.25

Cal 1-9 deg. 60 59.75 60.25

Difference between angles 3

Cal 1-8 deg. 75 74.75 75.25

Cal 1-8 deg. 75 74.75 75.25

Difference between angles 4

Cal 1-5 deg. 120 119.75 120.25

Cal 1-5 deg. 120 119.75 120.25

Difference between angles 5

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 6

Cal 1-11 deg. 180 179.75 180.25

Cal 1-11 deg. 180 179.75 180.25

Difference between angles 7

Cal 1-10 deg. 195 194.75 195.25

Cal 1-10 deg. 195 194.75 195.25

Difference between angles 8

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 9

Cal 1-6 deg. 255 254.75 255.25

Cal 1-6 deg. 255 254.75 255.25

Difference between angles 10

Cal 1-7 deg. 300 299.75 300.25

Cal 1-7 deg. 300 299.75 300.25

Difference between angles 11

Cal 1-12 deg. 315 314.75 315.25

Cal 1-12 deg. 315 314.75 315.25

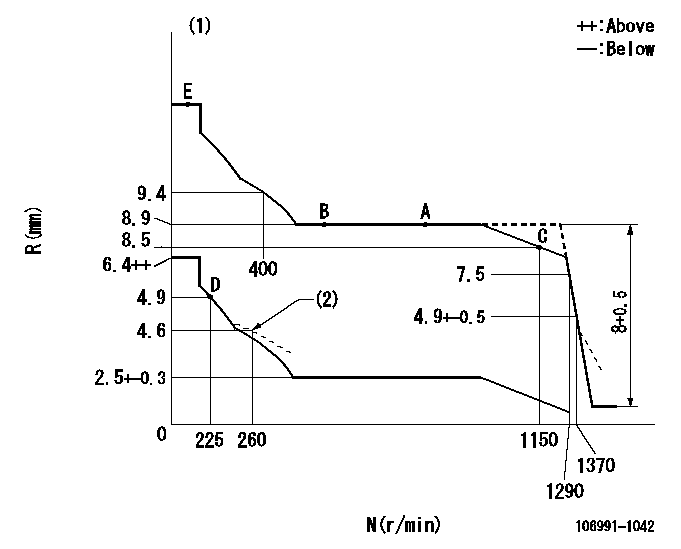

Injection quantity adjustment

Adjusting point

A

Rack position

8.9

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

112

110.5

113.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

8.5

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

124.9

122.9

126.9

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

4.9+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.8

6.8

10.8

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Damper spring setting

----------

----------

----------

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(7)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

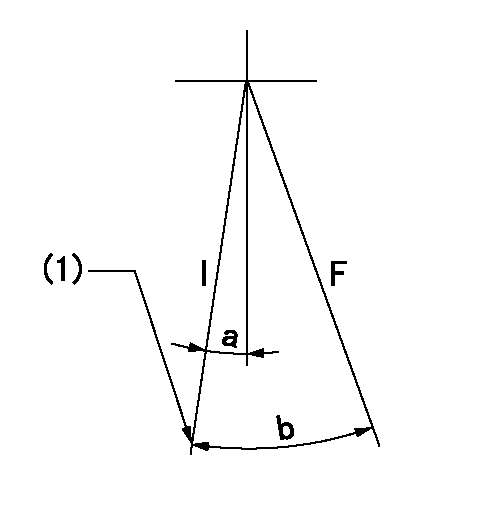

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34.5deg+-3deg

----------

----------

a=10deg+-5deg b=34.5deg+-3deg

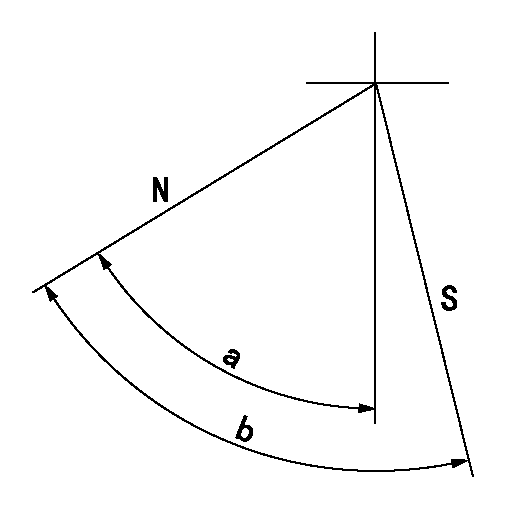

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

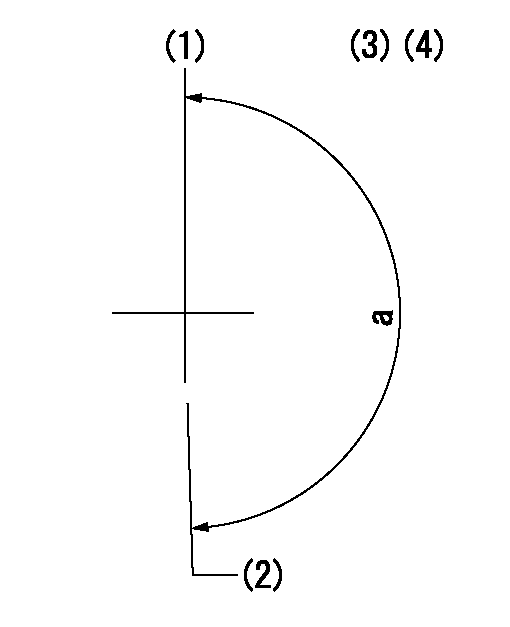

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa (set timing)

(4)-

----------

aa=8deg

----------

a=(180deg)

----------

aa=8deg

----------

a=(180deg)

Information:

Caterpillar: Confidential Yellow

PSP FOR REPLACING ERODED CYLINDER HEAD INJECTOR SLEEVES IN CERTAIN IT14B INTEGRATED TOOLCARRIERS; E110B, E120B, E200B, EL2 00B, 213B, 214B, 224B, E240B, EL240B EXCAVATORS; 446 BACKHOE LOADERS; AND 3114 AND 3116 INDUSTRIAL AND GENERATOR SET EN GINES - PS0456 - MAILED CFEL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

E-81 1100, 1290 PS0456 This Program can only be administered after a failure occurs. The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS0456" as Part Number, "7755" as Group Number, and "96" as Description Code. If this Program is administered on E200B or EL200B Excavators, it is recommended that the June 23, 1990 Service Letter - PS4442 be done at the same time. Termination Date

June 30, 1991

Problem

The fuel injector sleeves in the cylinder head of certain IT14B Integrated Toolcarriers; E110B, E120B, E200B, EL200B, 213B, 214B, 224B, E240B, and EL240B Excavators; 446 Backhoe Loaders; and 3114 and 3116 Industrial and Generator Set Engines are subject to pitting and erosion due to fuel cavitation between the injector and the sleeve. The sleeves may pit or crack through, allowing fuel to contaminate the coolant. Coolant contaminated with fuel may also damage the radiator and coolant hoses.

Affected Product

Model Identification Number IT14B 3NJ1-42 E110B 8MF1-151 E120B 6JF1-212 E200B* 6KF1-439 6KG1-249 EL200B* 7DF1-986 213B 1EJ1-233, 236-245, 247, 248 214B 4CF1-261, 263, 265-275, 278 9MF1-171, 173-182, 185 224B 7WF1-47, 51, 56, 65 E240B 8SF1-36 9PF1-196 EL240B 5WG1-166 6MG1-104 446 6XF1-227 3114 5EF1-675 6AF1-581 1ZG1-432 5JG1-743 3116 2SG1-936 2WG1-859 4PG1-611 1NJ1-999 * The E200B and EL200B Excavators need to be updated to a new injector design released for that machine. The new injectors have a different orifice size to help eliminate black smoke problems reported on some earlier machines. When replacing injectors on E200B and EL200B Excavators, use injector part number 7E8729 if available. Reset the fuel setting and timing if the injectors are available.

PSP FOR REPLACING ERODED CYLINDER HEAD INJECTOR SLEEVES IN CERTAIN IT14B INTEGRATED TOOLCARRIERS; E110B, E120B, E200B, EL2 00B, 213B, 214B, 224B, E240B, EL240B EXCAVATORS; 446 BACKHOE LOADERS; AND 3114 AND 3116 INDUSTRIAL AND GENERATOR SET EN GINES - PS0456 - MAILED CFEL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

E-81 1100, 1290 PS0456 This Program can only be administered after a failure occurs. The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS0456" as Part Number, "7755" as Group Number, and "96" as Description Code. If this Program is administered on E200B or EL200B Excavators, it is recommended that the June 23, 1990 Service Letter - PS4442 be done at the same time. Termination Date

June 30, 1991

Problem

The fuel injector sleeves in the cylinder head of certain IT14B Integrated Toolcarriers; E110B, E120B, E200B, EL200B, 213B, 214B, 224B, E240B, and EL240B Excavators; 446 Backhoe Loaders; and 3114 and 3116 Industrial and Generator Set Engines are subject to pitting and erosion due to fuel cavitation between the injector and the sleeve. The sleeves may pit or crack through, allowing fuel to contaminate the coolant. Coolant contaminated with fuel may also damage the radiator and coolant hoses.

Affected Product

Model Identification Number IT14B 3NJ1-42 E110B 8MF1-151 E120B 6JF1-212 E200B* 6KF1-439 6KG1-249 EL200B* 7DF1-986 213B 1EJ1-233, 236-245, 247, 248 214B 4CF1-261, 263, 265-275, 278 9MF1-171, 173-182, 185 224B 7WF1-47, 51, 56, 65 E240B 8SF1-36 9PF1-196 EL240B 5WG1-166 6MG1-104 446 6XF1-227 3114 5EF1-675 6AF1-581 1ZG1-432 5JG1-743 3116 2SG1-936 2WG1-859 4PG1-611 1NJ1-999 * The E200B and EL200B Excavators need to be updated to a new injector design released for that machine. The new injectors have a different orifice size to help eliminate black smoke problems reported on some earlier machines. When replacing injectors on E200B and EL200B Excavators, use injector part number 7E8729 if available. Reset the fuel setting and timing if the injectors are available.