Information injection-pump assembly

ZEXEL

106991-1032

1069911032

ISUZU

1156021882

1156021882

Rating:

Service parts 106991-1032 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-204-1

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106991-1032

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106991-1032

1069911032

ISUZU

1156021882

1156021882

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-4020

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4.2

4.17

4.23

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

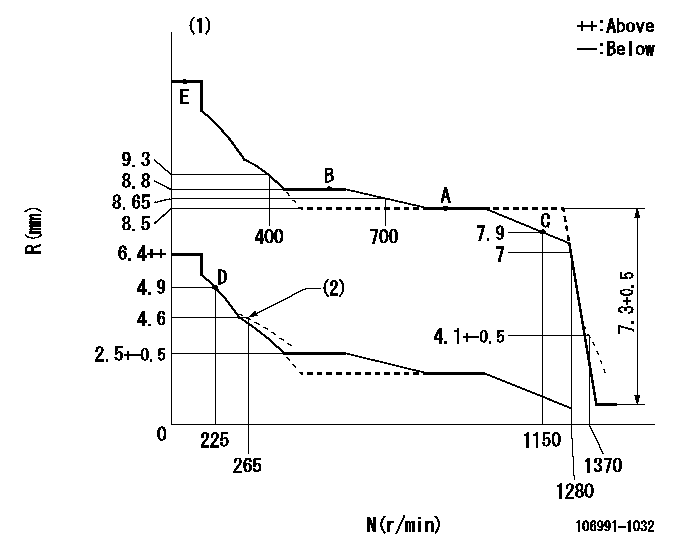

Adjusting point

A

Rack position

8.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

110

108.5

111.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.8

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

111.6

109.6

113.6

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

117.4

115.4

119.4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

4.9+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.8

7.5

10.1

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Damper spring setting

----------

----------

----------

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(7)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

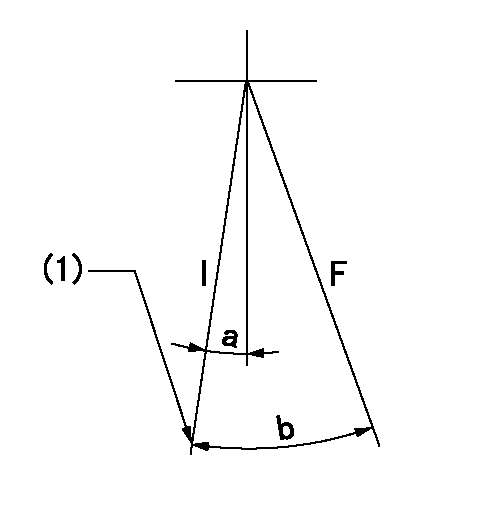

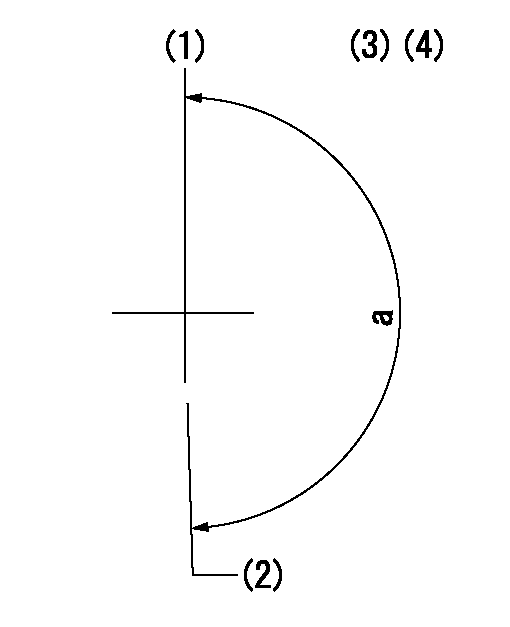

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34deg+-3deg

----------

----------

a=10deg+-5deg b=34deg+-3deg

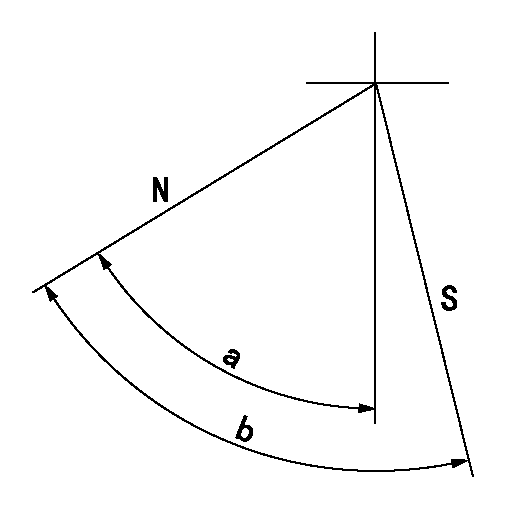

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa (set timing)

(4)-

----------

aa=8deg

----------

a=(180deg)

----------

aa=8deg

----------

a=(180deg)

Information:

Caterpillar: Confidential Yellow

PSP FOR INSTALLATION OF NEW INTERNAL FUEL INJECTION LINES ON CERTAIN 992C LOADERS; 773B TRUCKS; D9L, 651E, 657E, 772B TRA CTORS - MAILED US AND CANADA, CACO, COSA, LIMITED BRAZIL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

PRODUCT SUPPORT PROGRAM FOR INSTALLATION OF NEW INTERNAL FUEL INJECTION LINES ON CERTAIN 992C LOADERS; 773B TRUCKS; D9L, 651E, 657E, 772B TRACTORS, 1252, PS4094 U-116 A-52 C-112 B-10.1 O-84 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4094" as Part Number and "7755" as Group Number. Although products in the field are to be administered as described above, dealers should purge parts stock immediately. Termination Date

November 30, 1987

Problem

There have been some failures of the 2W8142 Line As. (internal fuel lines - under the valve cover) on the Affected Product. These failures have been cracks in the fuel lines which can result in poor engine performance and dilution of the engine oil with fuel. New fuel lines are now used in production.

Affected Product

Model Identification Number D9L 14Y2971, 3023-3039, 3041-3046, 3048-3139, 3141-3569, 3571-3609, 3611-3661, 3663-3675, 3677-3686, 3688-3697, 3699-3701, 3705-3707, 3709-3730, 3732-3775, 3777-3960, 3962-3966, 3974-3976, 3983 651E 89Z109 - 113, 116-142 657E 90Z127 - 133, 135-173 91Z217 - 282 772B 64W172, 173 773B 63W1443, 1462, 1464-1489, 1491-1827, 1831, 1836, 1842, 1843 992C 49Z622, 623, 626-628, 630, 634, 636, 638, 639, 641-643, 645-649, 651-765, 767-771, 773-819, 821-939, 944

Parts Needed

12 - 7C5570 Line As. Use as needed. If one or more 7C5570 Line As. have already been installed, they should not be replaced. Only replace the 2W8142 Line Assemblies.

Action Required

Parts Stock Remove all 2W8142 Line Assemblies from parts stock. Affected Product All 2W8142 Line Assemblies on an engine should be replaced at the same time. Install the new parts according to the procedures in the appropriate Service Manuals. WARRANTY ALLOWANCES Parts Stock Submit one claim for all 2W8142 Line Assemblies that are removed from parts stock. (SEE ILLUSTRATION)

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

PSP FOR INSTALLATION OF NEW INTERNAL FUEL INJECTION LINES ON CERTAIN 992C LOADERS; 773B TRUCKS; D9L, 651E, 657E, 772B TRA CTORS - MAILED US AND CANADA, CACO, COSA, LIMITED BRAZIL

The information supplied in this service letter may not be valid after the termination date of this program. Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

PRODUCT SUPPORT PROGRAM FOR INSTALLATION OF NEW INTERNAL FUEL INJECTION LINES ON CERTAIN 992C LOADERS; 773B TRUCKS; D9L, 651E, 657E, 772B TRACTORS, 1252, PS4094 U-116 A-52 C-112 B-10.1 O-84 This Program can be administered either before or after a failure. In either case the decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS4094" as Part Number and "7755" as Group Number. Although products in the field are to be administered as described above, dealers should purge parts stock immediately. Termination Date

November 30, 1987

Problem

There have been some failures of the 2W8142 Line As. (internal fuel lines - under the valve cover) on the Affected Product. These failures have been cracks in the fuel lines which can result in poor engine performance and dilution of the engine oil with fuel. New fuel lines are now used in production.

Affected Product

Model Identification Number D9L 14Y2971, 3023-3039, 3041-3046, 3048-3139, 3141-3569, 3571-3609, 3611-3661, 3663-3675, 3677-3686, 3688-3697, 3699-3701, 3705-3707, 3709-3730, 3732-3775, 3777-3960, 3962-3966, 3974-3976, 3983 651E 89Z109 - 113, 116-142 657E 90Z127 - 133, 135-173 91Z217 - 282 772B 64W172, 173 773B 63W1443, 1462, 1464-1489, 1491-1827, 1831, 1836, 1842, 1843 992C 49Z622, 623, 626-628, 630, 634, 636, 638, 639, 641-643, 645-649, 651-765, 767-771, 773-819, 821-939, 944

Parts Needed

12 - 7C5570 Line As. Use as needed. If one or more 7C5570 Line As. have already been installed, they should not be replaced. Only replace the 2W8142 Line Assemblies.

Action Required

Parts Stock Remove all 2W8142 Line Assemblies from parts stock. Affected Product All 2W8142 Line Assemblies on an engine should be replaced at the same time. Install the new parts according to the procedures in the appropriate Service Manuals. WARRANTY ALLOWANCES Parts Stock Submit one claim for all 2W8142 Line Assemblies that are removed from parts stock. (SEE ILLUSTRATION)

Parts Disposition

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.