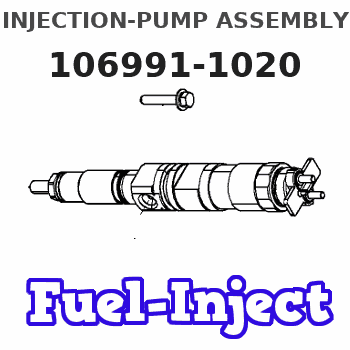

Information injection-pump assembly

ZEXEL

106991-1020

1069911020

ISUZU

1156025000

1156025000

Rating:

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Cooling System

Never add coolant to an overheated engine; allow the engine to cool first.Check the specific gravity of the antifreeze coolant solution frequently in cold weather to ensure adequate protection.If the machine is to be stored in, or shipped to, an area with below freezing temperatures; the cooling system must be protected against freezing to the lowest expected outside temperature.All water is corrosive at engine operating temperature. The cooling system should be protected with conditioner at all times regardless of the concentration of antifreeze. This can be done by using Caterpillar coolant conditioner elements. Use a precharge element when filling the system or changing coolant. Install a new maintenance element every 250 service hours during operation.Do not use Caterpillar coolant conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.

Coolant should be drained and replaced every 2000 service hours or 1 year. However, when coolant conditioner maintenance elements are replaced every 250 service hours as recommended, the drain period can be extended to 4000 service hours or 2 years. If your engine does not use coolant conditioner elements, see "Cooling System" under "Maintenance Recommendations" in your Maintenance (Lubrication and Maintenance) Guide.Premix antifreeze coolant solution to provide protection to the lowest expected outside temperature. Pure undiluted antifreeze will freeze at -23°C (-10°F).Use clean water that is low in scale forming mineral. Do not use softened water.Filling at over 20 liters (5 U.S. gallons) per minute can cause air pockets in the cooling system.After draining and refilling the cooling system, start and operate the engine with the fill cap off until the coolant level stabilizes. Add coolant as necessary to fill the system.When the engine is shipped from the factory, its cooling system is protected to -28°C (-20°F), with permanent-type antifreeze.Operate with a thermostat in the cooling system year-round. Overheating can arise without a thermostat.Fuel System

Fill the fuel tank at the end of each day of operation to drive out moist air and to prevent condensation. Do not fill the tank to the top. The fuel expands as it gets warm and may overflow.

Do not fill the fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to the fuel system parts.

Check the fuel level with the dipstick in the filler opening. Drain the water and sediment from the fuel tank at the start of a shift or after the fuel tank has been filled and allowed to stand for 5 to 10 minutes.After changing the fuel filters, always bleed the fuel system to remove air bubbles from the system.Drain water and sediment from any fuel storage tank weekly, and before the tank is refilled. This will help prevent water or sediment from being pumped from the storage tank into the machine fuel tank.Use only fuel as recommended in the 'Fuel, Coolant and Lubricant" section of this Guide.

Never add coolant to an overheated engine; allow the engine to cool first.Check the specific gravity of the antifreeze coolant solution frequently in cold weather to ensure adequate protection.If the machine is to be stored in, or shipped to, an area with below freezing temperatures; the cooling system must be protected against freezing to the lowest expected outside temperature.All water is corrosive at engine operating temperature. The cooling system should be protected with conditioner at all times regardless of the concentration of antifreeze. This can be done by using Caterpillar coolant conditioner elements. Use a precharge element when filling the system or changing coolant. Install a new maintenance element every 250 service hours during operation.Do not use Caterpillar coolant conditioner elements with Dowtherm 209 Full-Fill coolant. Follow the instructions provided with the Dowtherm 209 Full-Fill coolant.

Coolant should be drained and replaced every 2000 service hours or 1 year. However, when coolant conditioner maintenance elements are replaced every 250 service hours as recommended, the drain period can be extended to 4000 service hours or 2 years. If your engine does not use coolant conditioner elements, see "Cooling System" under "Maintenance Recommendations" in your Maintenance (Lubrication and Maintenance) Guide.Premix antifreeze coolant solution to provide protection to the lowest expected outside temperature. Pure undiluted antifreeze will freeze at -23°C (-10°F).Use clean water that is low in scale forming mineral. Do not use softened water.Filling at over 20 liters (5 U.S. gallons) per minute can cause air pockets in the cooling system.After draining and refilling the cooling system, start and operate the engine with the fill cap off until the coolant level stabilizes. Add coolant as necessary to fill the system.When the engine is shipped from the factory, its cooling system is protected to -28°C (-20°F), with permanent-type antifreeze.Operate with a thermostat in the cooling system year-round. Overheating can arise without a thermostat.Fuel System

Fill the fuel tank at the end of each day of operation to drive out moist air and to prevent condensation. Do not fill the tank to the top. The fuel expands as it gets warm and may overflow.

Do not fill the fuel filters with fuel before installing them. Contaminated fuel will cause accelerated wear to the fuel system parts.

Check the fuel level with the dipstick in the filler opening. Drain the water and sediment from the fuel tank at the start of a shift or after the fuel tank has been filled and allowed to stand for 5 to 10 minutes.After changing the fuel filters, always bleed the fuel system to remove air bubbles from the system.Drain water and sediment from any fuel storage tank weekly, and before the tank is refilled. This will help prevent water or sediment from being pumped from the storage tank into the machine fuel tank.Use only fuel as recommended in the 'Fuel, Coolant and Lubricant" section of this Guide.