Information injection-pump assembly

ZEXEL

106991-1005

1069911005

ISUZU

1156021875

1156021875

Rating:

Service parts 106991-1005 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-204-1

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106991-1005

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106991-1005

1069911005

ISUZU

1156021875

1156021875

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-4020

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4.2

4.17

4.23

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

110

108.5

111.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.8

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

111.6

109.6

113.6

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

117.4

115.4

119.4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

4.9+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.8

7.5

10.1

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

600--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

550

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

800+-30

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

870

Advance angle

deg.

2

1.7

2.3

Timer adjustment_05

Pump speed

r/min

(1050)

Advance angle

deg.

3.5

3

4

Timer adjustment_06

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

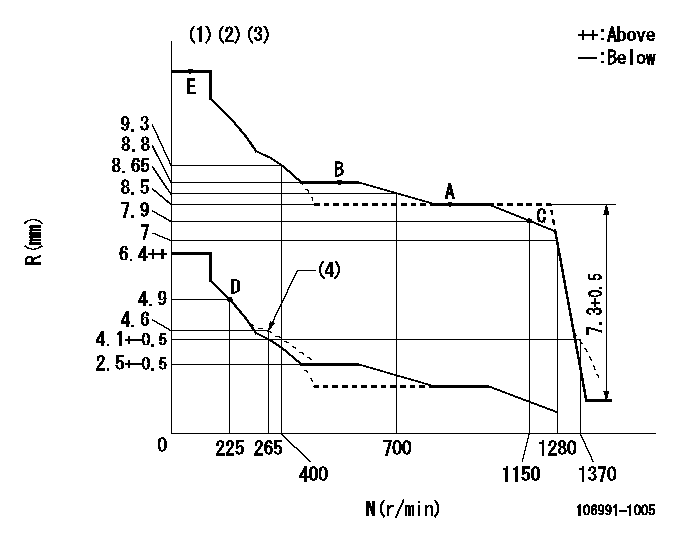

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Damper spring setting

----------

RT=0.8 TH=2mm

----------

----------

RT=0.8 TH=2mm

----------

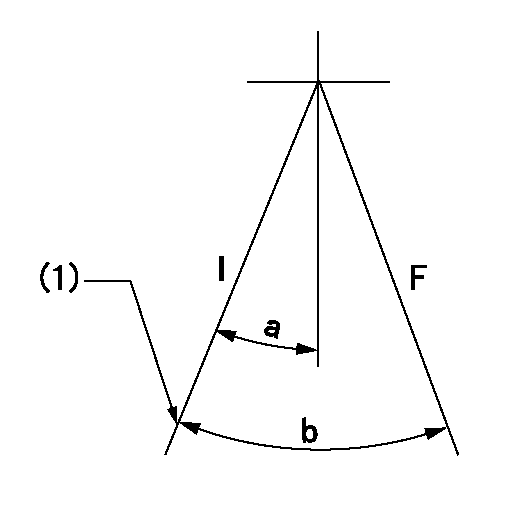

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34deg+-3deg

----------

----------

a=10deg+-5deg b=34deg+-3deg

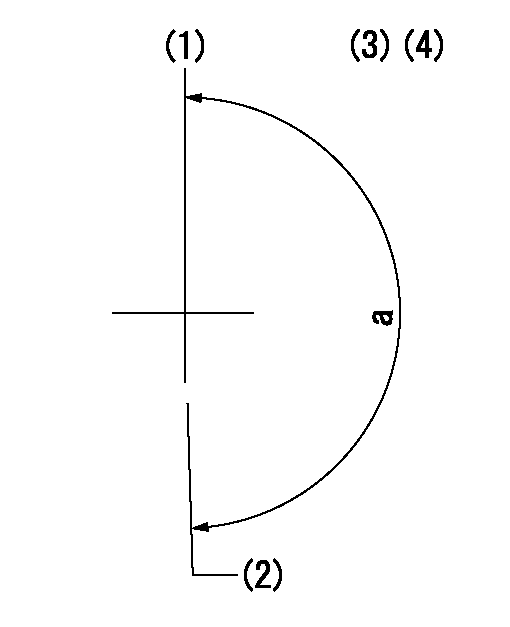

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa (set timing)

(4)-

----------

aa=8deg

----------

a=(180deg)

----------

aa=8deg

----------

a=(180deg)

Information:

Above 32°F (0°C)

Make sure no one is working on or close to the machine before starting the engine. Fasten seat belt.

1. Make certain TRANSMISSION NEUTRAL LOCK and PARKING BRAKE LOCKING lever is engaged. Move all implement controls to HOLD. 2. Insert the key in the disconnect switch and turn the switch ON.

Never turn the disconnect switch OFF with the engine running.

3. Move the governor control lever to the low idle position just past the detent. 4. Push in and turn the START switch to START. Release the switch when the engine starts.Below 32°F (0°C)

1. Follow steps 1-thru-4 for above 32°F (0°C). If engine does not start, push in the Starting Aid Button. A metered amount of starting fluid, sufficient to help start the engine, is released each time the Starting Aid Button is pushed in. 2. While cranking the engine use additional Starting Aid Fluid every 2 seconds, by pushing the button in and releasing it. 3. Release the START switch when the engine starts.4. If necessary continue the use of Starting Aid Fluid every 2 seconds after the engine starts, until it runs smoothly.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

5. If extra battery capacity is needed, refer to the Operator's Guide SEBU5516 - 955L, 977L & 983B Track Type Loaders.6. Refer to the Operator's Guide for after starting checks, warm up procedure and engine shutdown. For starting below 0°F (-18°C) the use of optional cold weather starting aids is recommended. A coolant heater, jacket water heater or extra battery capacity may be required.

The Starting Aid Ether Bottle must be removed before transporting the machine. See the Lubrication and Maintenance Guide SEBU5515 for removal and replacing the bottle.

Make sure no one is working on or close to the machine before starting the engine. Fasten seat belt.

1. Make certain TRANSMISSION NEUTRAL LOCK and PARKING BRAKE LOCKING lever is engaged. Move all implement controls to HOLD. 2. Insert the key in the disconnect switch and turn the switch ON.

Never turn the disconnect switch OFF with the engine running.

3. Move the governor control lever to the low idle position just past the detent. 4. Push in and turn the START switch to START. Release the switch when the engine starts.Below 32°F (0°C)

1. Follow steps 1-thru-4 for above 32°F (0°C). If engine does not start, push in the Starting Aid Button. A metered amount of starting fluid, sufficient to help start the engine, is released each time the Starting Aid Button is pushed in. 2. While cranking the engine use additional Starting Aid Fluid every 2 seconds, by pushing the button in and releasing it. 3. Release the START switch when the engine starts.4. If necessary continue the use of Starting Aid Fluid every 2 seconds after the engine starts, until it runs smoothly.

After every 30 seconds of cranking, allow 2 minutes for the starting motor to cool.

5. If extra battery capacity is needed, refer to the Operator's Guide SEBU5516 - 955L, 977L & 983B Track Type Loaders.6. Refer to the Operator's Guide for after starting checks, warm up procedure and engine shutdown. For starting below 0°F (-18°C) the use of optional cold weather starting aids is recommended. A coolant heater, jacket water heater or extra battery capacity may be required.

The Starting Aid Ether Bottle must be removed before transporting the machine. See the Lubrication and Maintenance Guide SEBU5515 for removal and replacing the bottle.