Information injection-pump assembly

BOSCH

9 400 618 711

9400618711

ZEXEL

106971-5150

1069715150

NISSAN-DIESEL

1680197010

1680197010

Rating:

Cross reference number

BOSCH

9 400 618 711

9400618711

ZEXEL

106971-5150

1069715150

NISSAN-DIESEL

1680197010

1680197010

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

4.4

4.37

4.43

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.75 45.25

Cal 10-9 deg. 45 44.75 45.25

Difference between angles 2

Cal 10-4 deg. 72 71.75 72.25

Cal 10-4 deg. 72 71.75 72.25

Difference between angles 3

Cal 10-3 deg. 117 116.75 117.25

Cal 10-3 deg. 117 116.75 117.25

Difference between angles 4

Cal 10-6 deg. 144 143.75 144.25

Cal 10-6 deg. 144 143.75 144.25

Difference between angles 5

Cal 10-5 deg. 189 188.75 189.25

Cal 10-5 deg. 189 188.75 189.25

Difference between angles 6

Cal 10-8 deg. 216 215.75 216.25

Cal 10-8 deg. 216 215.75 216.25

Difference between angles 7

Cal 10-7 deg. 261 260.75 261.25

Cal 10-7 deg. 261 260.75 261.25

Difference between angles 8

Cal 10-2 deg. 288 287.75 288.25

Cal 10-2 deg. 288 287.75 288.25

Difference between angles 9

Cal 10-1 deg. 333 332.75 333.25

Cal 10-1 deg. 333 332.75 333.25

Injection quantity adjustment

Rack position

(13.4)

Vist

V

1.84

1.84

1.84

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

131.5

129.5

133.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Injection quantity adjustment_02

Rack position

(8.8)

Vist

V

2.5

2.4

2.6

Pump speed

r/min

370

370

370

Average injection quantity

mm3/st.

16

14

18

Max. variation between cylinders

%

0

-10

10

Test data Ex:

Governor adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(9)deg t1=1.7--sec. t2=1.7--sec.

----------

N1=1000++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=9+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(9)deg t1=1.7--sec. t2=1.7--sec.

----------

N1=1000++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=9+-0.3deg R01=0/4load R02=4/4load

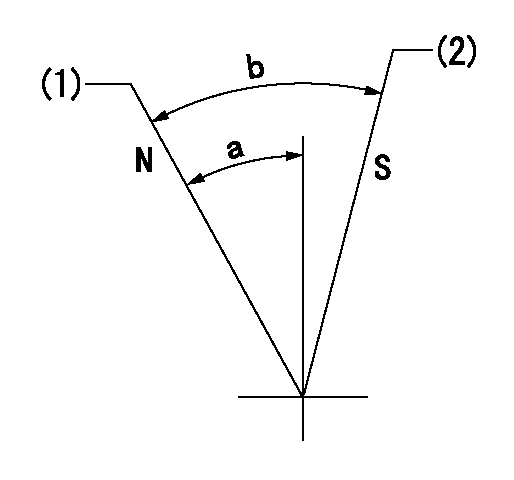

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

0000000901

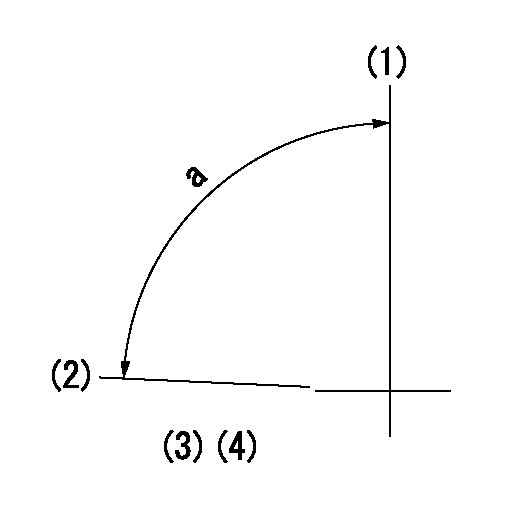

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

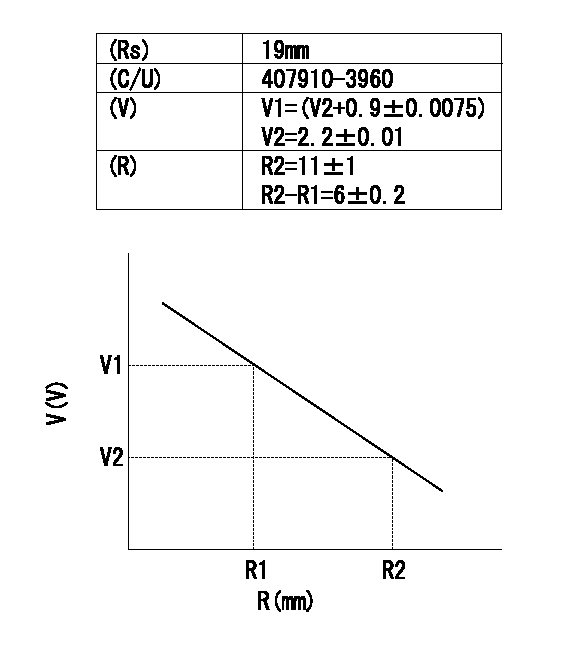

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Start By:a. remove oil pumpb. remove oil pan plate 1. Turn the crankshaft until two pistons are at the bottom center. Remove connecting rod caps (1) from the two connecting rods. Remove the lower half of the rod bearing from the rod bearing cap.2. Push the connecting rods away from the crankshaft. Remove the upper half of the rod bearing from the connecting rod. Install the connecting rod bearings dry when the clearance checks are made. Put clean engine oil on the connecting rod bearings for final assembly.3. Install the upper half of the rod bearing in the connecting rod.4. Install the lower half of the rod bearing in the connecting rod cap. Be sure the tabs in the back of the connecting rod bearings are in the tab grooves of the connecting rod and cap. 5. Use Plastigage (A) to check the connecting rod bearing clearance.6. Put Plastigage (A) on the connecting rod bearing.7. Put 2P2506 Thread Lubricant on the threads of the rod bolts and seat surfaces of the nuts.

When connecting rod caps are installed, make sure the number on the side of the cap is next to and respective with the number on the side of the connecting rod.

Do not turn the crankshaft when Plastigage (A) is in position.

Do not use an impact wrench to tighten the nuts the additional 90°.

8. Install connecting rod cap (1). Install the nuts. Tighten the nuts to a torque of 40 4 N m (30 3 lb ft). Put a mark on each nut and the end of each bolt. Tighten the nuts 90° more. Remove the connecting rod caps. Remove Plastigage (A) and measure the width of the Plastigage. The connecting rod clearance must be 0.076 to 0.168 mm (.0030 to .0066 in) for new bearings. The maximum clearance with used bearings is 0.25 mm (.010 in).9. Install the connecting rod caps and tighten the nuts as in Step 8.10. Do Steps 1 through 9 for the remainder of the connecting rod bearings.End By:a. install oil pan plateb. install oil pump

When connecting rod caps are installed, make sure the number on the side of the cap is next to and respective with the number on the side of the connecting rod.

Do not turn the crankshaft when Plastigage (A) is in position.

Do not use an impact wrench to tighten the nuts the additional 90°.

8. Install connecting rod cap (1). Install the nuts. Tighten the nuts to a torque of 40 4 N m (30 3 lb ft). Put a mark on each nut and the end of each bolt. Tighten the nuts 90° more. Remove the connecting rod caps. Remove Plastigage (A) and measure the width of the Plastigage. The connecting rod clearance must be 0.076 to 0.168 mm (.0030 to .0066 in) for new bearings. The maximum clearance with used bearings is 0.25 mm (.010 in).9. Install the connecting rod caps and tighten the nuts as in Step 8.10. Do Steps 1 through 9 for the remainder of the connecting rod bearings.End By:a. install oil pan plateb. install oil pump