Information injection-pump assembly

BOSCH

9 400 618 699

9400618699

ZEXEL

106971-5020

1069715020

NISSAN-DIESEL

1671397179

1671397179

Rating:

Service parts 106971-5020 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.6(230)

15.

NOZZLE SET

Include in #1:

106971-5020

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 699

9400618699

ZEXEL

106971-5020

1069715020

NISSAN-DIESEL

1671397179

1671397179

Zexel num

Bosch num

Firm num

Name

106971-5020

9 400 618 699

1671397179 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RD10T03 K 14CE INJECTION PUMP ASSY PE10P PE

RD10T03 K 14CE INJECTION PUMP ASSY PE10P PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.1

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

138.5

137.5

139.5

Max. variation between cylinders

%

0

-2.5

2.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

38

38

Boost pressure

mmHg

285

285

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.8

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

109.5

107.5

111.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

13

11.9

14.1

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

125

135

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

10.8

Boost pressure

kPa

16

9.3

22.7

Boost pressure

mmHg

120

70

170

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(12.1)

Boost pressure

kPa

30

28.7

31.3

Boost pressure

mmHg

225

215

235

Timer adjustment

Pump speed

r/min

300+100

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

3.4

2.9

3.9

Timer adjustment_04

Pump speed

r/min

1250+50

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

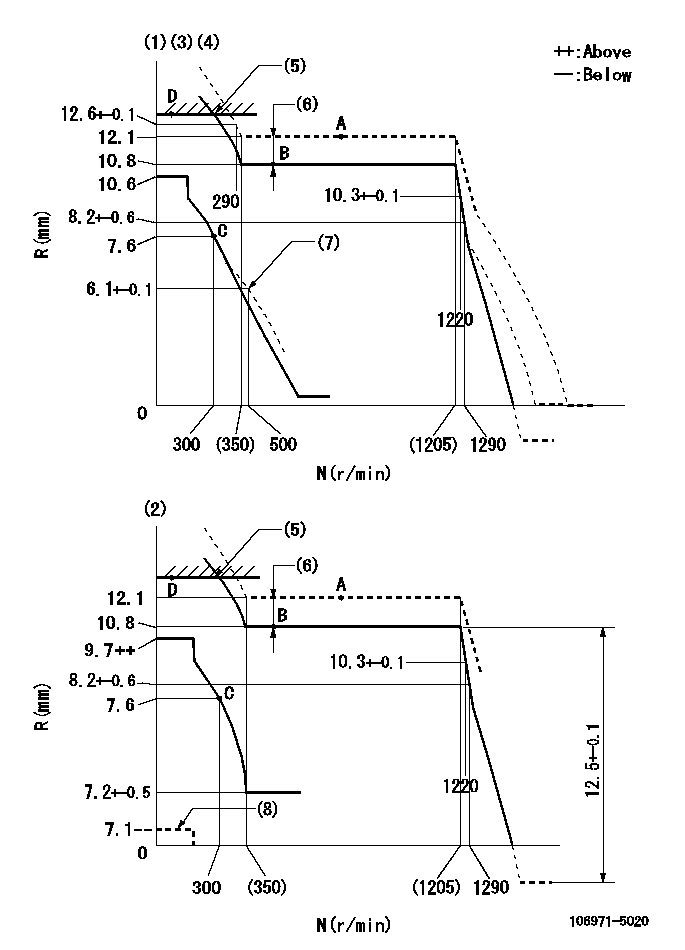

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Variable speed specification (load control lever at full position)

(2)Minimum - maximum speed specification (speed control lever full position)

(3)Target notch: K

(4)Tolerance for racks not indicated: +-0.05mm.

(5)RACK LIMIT

(6)Boost compensator stroke: BCL

(7)Damper spring setting

(8)Set the load lever at the stop position.

----------

K=17 BCL=(1.3)mm

----------

----------

K=17 BCL=(1.3)mm

----------

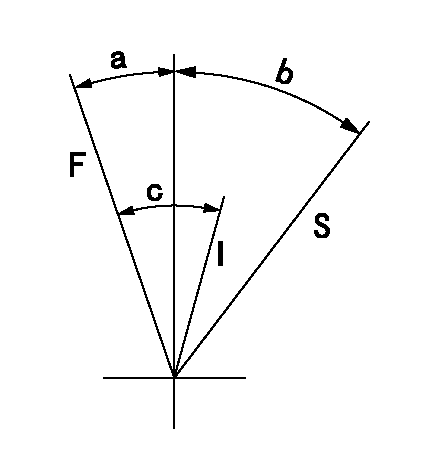

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=8deg+-5deg b=32deg+-3deg c=23deg+-5deg

----------

----------

a=8deg+-5deg b=32deg+-3deg c=23deg+-5deg

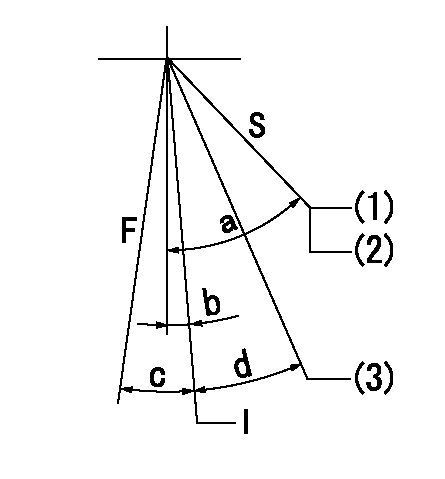

0000000901

F:Full load

I:Idle

S:Stop

(1)Position where contacts boss

(2)Rack position = aa or less (speed = bb)

(3)Rack position = cc (speed = dd)

----------

aa=7.1mm bb=0r/min cc=7.1-0.2mm dd=0r/min

----------

a=(46deg) b=0deg+-5deg c=6deg+-3deg d=21deg+-5deg

----------

aa=7.1mm bb=0r/min cc=7.1-0.2mm dd=0r/min

----------

a=(46deg) b=0deg+-5deg c=6deg+-3deg d=21deg+-5deg

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Maximum no-load speed (r/min)

LABEL9:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)At high idle rack position L

----------

L=8.2mm

----------

a1=A a2=B a3=C a4=D r1=- r2=750r/min r3=700r/min r4=700r/min Q1=- Q2=138.5+-1mm3/st Q3=126.5+-1mm3/st Q4=103+-1mm3/st c1=- c2=+-2.5 c3=+-2.5 c4=+-2.5 a5=24 a6=23 a7=22 a8=21 a9=20 a10=19 a11=18 a12=17 a13=16 a14=15 a15=- r5=1200r/min r6=1150r/min r7=1100r/min r8=1050r/min r9=1000r/min r10=950r/min r11=900r/min r12=850r/min r13=800r/min r14=750r/min r15=- R5=1290+-30r/min R6=1235+-28r/min R7=1180+-27r/min R8=1130+-26r/min R9=1075+-25r/min R10=1020+-23r/min R11=965+-22r/min R12=915+-22r/min R13=860+-20r/min R14=805+-18r/min R15=-

----------

L=8.2mm

----------

a1=A a2=B a3=C a4=D r1=- r2=750r/min r3=700r/min r4=700r/min Q1=- Q2=138.5+-1mm3/st Q3=126.5+-1mm3/st Q4=103+-1mm3/st c1=- c2=+-2.5 c3=+-2.5 c4=+-2.5 a5=24 a6=23 a7=22 a8=21 a9=20 a10=19 a11=18 a12=17 a13=16 a14=15 a15=- r5=1200r/min r6=1150r/min r7=1100r/min r8=1050r/min r9=1000r/min r10=950r/min r11=900r/min r12=850r/min r13=800r/min r14=750r/min r15=- R5=1290+-30r/min R6=1235+-28r/min R7=1180+-27r/min R8=1130+-26r/min R9=1075+-25r/min R10=1020+-23r/min R11=965+-22r/min R12=915+-22r/min R13=860+-20r/min R14=805+-18r/min R15=-

Information:

Termination Date

October 31, 1993Problem

Certain 2S7264 and 3S1467 Fuel Injection Pump Assemblies need to be removed from parts stock.

Action Required

Remove all 2S7264 and 3S1467 Fuel Injection Pump Assemblies from parts stock with date codes of December 1992 through March 1993. The date code appears at the bottom of the part number label on the pump box. The first two numbers indicate the month and the next two numbers indicate the year as shown in the example below:

Service Claim Allowances

Submit one claim for all 2S7264 and 3S1467 Fuel Injection Pump Assemblies removed from parts stock.

US and Canadian Dealers Only - When submitting a parts stock claim use 99Z00007 in the Product Identification Number Field.

Parts Disposition

U.S. And Canadian Dealers

Return all 2S7264 and 3S1467 Fuel Injection Pump Assemblies that are removed from parts stock and a copy of the claim to:

Caterpillar Inc.

Memory Lane

B Receiving

York, PA 17402

Attention: Quality Dept./PI7318

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

October 31, 1993Problem

Certain 2S7264 and 3S1467 Fuel Injection Pump Assemblies need to be removed from parts stock.

Action Required

Remove all 2S7264 and 3S1467 Fuel Injection Pump Assemblies from parts stock with date codes of December 1992 through March 1993. The date code appears at the bottom of the part number label on the pump box. The first two numbers indicate the month and the next two numbers indicate the year as shown in the example below:

Service Claim Allowances

Submit one claim for all 2S7264 and 3S1467 Fuel Injection Pump Assemblies removed from parts stock.

US and Canadian Dealers Only - When submitting a parts stock claim use 99Z00007 in the Product Identification Number Field.

Parts Disposition

U.S. And Canadian Dealers

Return all 2S7264 and 3S1467 Fuel Injection Pump Assemblies that are removed from parts stock and a copy of the claim to:

Caterpillar Inc.

Memory Lane

B Receiving

York, PA 17402

Attention: Quality Dept./PI7318

All Other Dealers

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Have questions with 106971-5020?

Group cross 106971-5020 ZEXEL

Nissan-Diesel

106971-5020

9 400 618 699

1671397179

INJECTION-PUMP ASSEMBLY

RD10T03

RD10T03