Information injection-pump assembly

ZEXEL

106971-3120

1069713120

HINO

220007180A

220007180a

Rating:

Cross reference number

ZEXEL

106971-3120

1069713120

HINO

220007180A

220007180a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0820

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-10-9-4

-3-6-5-8

-7-2

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-10 deg. 27 26.75 27.25

Cal 1-10 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-9 deg. 72 71.75 72.25

Cal 1-9 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-4 deg. 99 98.75 99.25

Cal 1-4 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-3 deg. 144 143.75 144.25

Cal 1-3 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-6 deg. 171 170.75 171.25

Cal 1-6 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-5 deg. 216 215.75 216.25

Cal 1-5 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-8 deg. 243 242.75 243.25

Cal 1-8 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-7 deg. 288 287.75 288.25

Cal 1-7 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

123.5

121.5

125.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

125.2

122.2

128.2

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.7

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

124.4

121.4

127.4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

4.3+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10.8

7.8

13.8

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

G

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

161

161

181

Fixing the lever

*

Timer adjustment

Pump speed

r/min

680--

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

630

Advance angle

deg.

0.3

Load

1/4

Timer adjustment_03

Pump speed

r/min

770--

Advance angle

deg.

1

0.7

1.3

Load

4/4

Timer adjustment_04

Pump speed

r/min

900+50

Advance angle

deg.

1

0.7

1.3

Load

3/4

Timer adjustment_05

Pump speed

r/min

1100-50

Advance angle

deg.

5.25

4.95

5.55

Load

4/4

Remarks

Finish

Finish

Test data Ex:

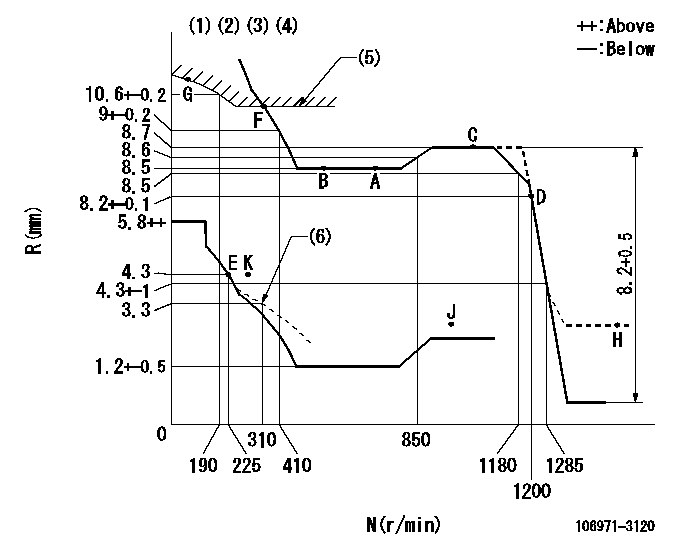

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Set idle at point K (N = N1, R = R1) and confirm that the injection quantity does not exceed Q1 at point J (N = N2).

(5)Excess fuel setting for starting: SXL

(6)Damper spring setting

----------

RT=0.8 TH=3mm N1=300r/min R1=4.3mm N2=1000r/min Q1=3mm3/st SXL=10.1+-0.1mm

----------

----------

RT=0.8 TH=3mm N1=300r/min R1=4.3mm N2=1000r/min Q1=3mm3/st SXL=10.1+-0.1mm

----------

Speed control lever angle

F:Full speed

----------

----------

a=13.5deg+-5deg

----------

----------

a=13.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=61mm

----------

a=39deg+-3deg b=17deg+-5deg

----------

aa=61mm

----------

a=39deg+-3deg b=17deg+-5deg

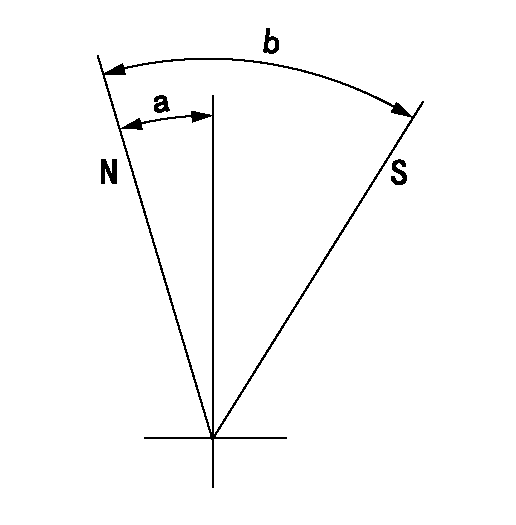

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=16deg+-5deg b=64deg+-5deg

----------

----------

a=16deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(80deg)

----------

----------

a=(80deg)

Information:

This Revised Service Letter replaces the 05Dec2012 (Revised 31Jan2013) Service Letter. Changes have been made to the Affected Product and Action Required.

TERMINATION DATE

31Dec2013

PROBLEM

The existing fuel injector has a 150 degree spray pattern. During the combustion stroke (process), the current end of injection timing maps can allow the 150 degree spray pattern to temporarily impinge upon the exposed wall of the cylinder liner as the piston moves downward in the bore.

Depending on engine speed and load factors, the fuel making contact with the liner can dilute the oil film or cause excessive soot. The excessive soot can build up to form carbon deposits at the piston lands and grooves, resulting in uneven top ring and groove wear, which may cause ring breakage. This situation is aggravated by contamination within the air and lubrication systems.

AFFECTED PRODUCT

Model Identification Number

793D FDB00105-01737, 1739

PARTS NEEDED

Qty

Part Number Description

16 20R2296 INJECTOR GP-FUEL

1 4264383 SOFTWARE GP-ELEK

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 7% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

This program does not apply to 793D Off-Highway Trucks equipped with high altitude engine arrangements.

If a 793D Off-Highway Truck that is listed in the Affected Product already has 423-7547 Fuel Injectors or 20R-2296 Fuel Injectors installed, do not apply this Service Letter.

Refer to the service manual if/as necessary.

Install a full set of sixteen 145 degree fuel injectors along with the software.

NOTE 1: Do not mix the 145 degree fuel injectors with the former 150 degree fuel injectors in the same engine.

NOTE 2: Do not install the software that is listed in the Parts Needed unless all sixteen fuel injectors have been replaced by the 145 degree spray pattern fuel injectors that is listed in the Parts Needed.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-1000 hrs,

0-6 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 8.0-hour job

If there has been a previous repair, part age/hours will apply. Retain a copy of the previous repair invoice in the dealer's records for audit purposes, and specify repair date and machine hours in the "Additional Comments" section of the warranty claim.

If the engine is out of chassis for Planned Component Rebuild (PCR), the software and injectors should be installed. However, the costs for the software and injector update are not covered under this program.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.