Information injection-pump assembly

ZEXEL

106971-0600

1069710600

Rating:

Service parts 106971-0600 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660097005

12.

Open Pre:MPa(Kqf/cm2)

22.6(230)

15.

NOZZLE SET

Include in #1:

106971-0600

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106971-0600

1069710600

Zexel num

Bosch num

Firm num

Name

106971-0600

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3

2.95

3.05

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

13.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

165

163

167

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.9

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

132.6

130.6

134.6

Max. variation between cylinders

%

0

-4

4

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.3+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

17.8

15.8

19.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

2.3

1.8

2.8

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

3.5

3.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

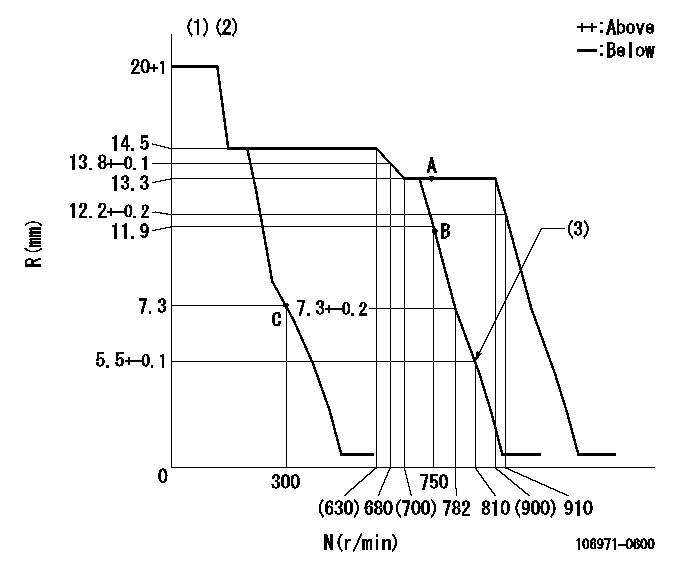

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

----------

K=10

----------

----------

K=10

----------

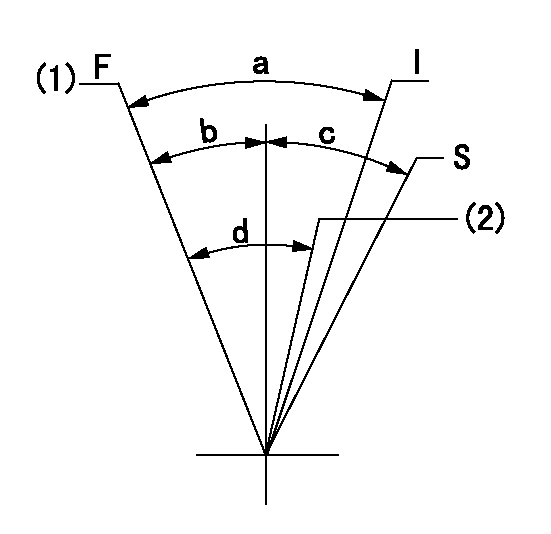

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Set the pump speed at aa

(2)Set the pump speed at bb.

----------

aa=900r/min bb=750r/min

----------

a=27deg+-5deg b=4deg+-5deg c=32deg+-3deg d=7deg+-5deg

----------

aa=900r/min bb=750r/min

----------

a=27deg+-5deg b=4deg+-5deg c=32deg+-3deg d=7deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

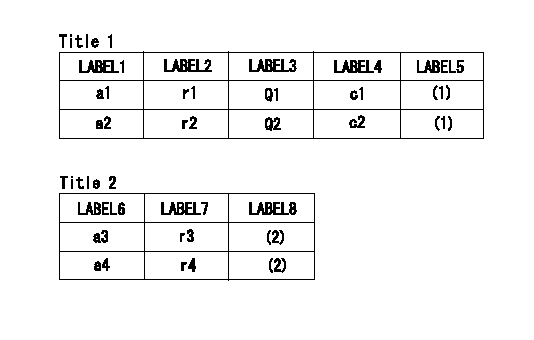

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=A a2=E r1=750r/min r2=750r/min Q1=165+-2mm3/st Q2=180+-2mm3/st c1=+-4% c2=+-4% a3=18 a4=15 r3=900r/min r4=750r/min

----------

----------

a1=A a2=E r1=750r/min r2=750r/min Q1=165+-2mm3/st Q2=180+-2mm3/st c1=+-4% c2=+-4% a3=18 a4=15 r3=900r/min r4=750r/min

Information:

2. Removing Accessories

(1) Removing Fan(a) Reduce the tension applied by the tension pulley by pushing the alternator toward the engine, then remove the water pump drive belt (1).(b) Remove the fan mounting bolts (2), then remove the fan (3).(c) Remove the water pump pulley (4), which was previously retained by the fan mounting bolts (2).(2) Removing Thermostat FittingRemove the water outlet fitting (1), then remove the thermostat (2), thermostat fitting (3), water joint (4), and temperature joint (5) in that sequence. (3) Removing Exhaust and Intake Manifolds(a) Remove the exhaust manifold mounting bolts, then remove the exhaust manifold (1) and the gasket (2).(b) Remove the intake manifold mounting bolts, then remove the intake manifold (3) and the gasket (4). When refitting the manifolds, fit each gasket with the side marked "MANIFOLD" facing the manifold. (4) Removing Water PumpRemove the water pump mounting bolts, then remove the water pump (1). (5) Removing Alternator(a) Disconnect the battery cables.(b) Disconnect the lead from terminal B at the rear of the alternator.(c) Remove the alternator connector.(d) Loosen the alternator brace bolt (1) and support bolt (2), then push the alternator toward the engine and remove the fan belt.(e) Remove the alternator. (6) Removing Starter(a) Disconnect the battery's (-) and (+) terminals in that sequence.(b) Disconnect the start wiring (1).(c) Remove the starter's two mounting bolts (2), then remove the starter (3). (7) Removing Oil Filter(a) The oil filter (2) must be replaced every 100 hours of use.(b) Remove the oil filter using a filter wrench (1). (8) Removing Fuel Filter(a) Remove the fuel pipe (1) that leads from the fuel tank and the fuel pipe (2) that leads to the fuel pump.(b) Remove the fuel filter (3) from the engine. (9) Removing Fuel Pipes(a) Remove the clamps from the four fuel pipes (1), then disconnect the fuel pipes from the engine and from the injection pump.(b) Remove the joints and clips from the fuel hose (2), then disconnect the fuel hose from the injector holders.

To keep dirt out of the fuel system, fit rubber caps over the parts of the injection pump and injector inlet connectors from which the injection pipes are disconnected.

(10) Removing Injection Pump

1 Fuel hose2 Fuel pipe3 Tie rod cover4 Tie rod spring5 Tie rod6 Injection pump7 Adjustment shim8 Control rack pin(a) Remove the tie rod cover (3).

Removing tie rod cover(b) Using long-nosed pliers, remove the tie rod spring (4) from the control rack pin (8) and from the governor lever pin.(c) Remove the tie rod (5).

Removing tie rod(d) Remove the injection pump (6) and the adjustment shim (7).

Removing injection pump(11) Removing Oil PumpRemove the oil pump's four mounting bolts, then remove the oil pump (1). (12) Removing InjectorDisconnect the fuel injection pipe (1) and the fuel hose (2) before removing the injector (3). 3. Refitting Accessories

3.1 General PointsRefit accessories by following the removal procedures in reverse. After refitting accessories, perform the following operations:(1) Pour the specified amount of engine oil into the engine.(2) Pour coolant into the cooling

(1) Removing Fan(a) Reduce the tension applied by the tension pulley by pushing the alternator toward the engine, then remove the water pump drive belt (1).(b) Remove the fan mounting bolts (2), then remove the fan (3).(c) Remove the water pump pulley (4), which was previously retained by the fan mounting bolts (2).(2) Removing Thermostat FittingRemove the water outlet fitting (1), then remove the thermostat (2), thermostat fitting (3), water joint (4), and temperature joint (5) in that sequence. (3) Removing Exhaust and Intake Manifolds(a) Remove the exhaust manifold mounting bolts, then remove the exhaust manifold (1) and the gasket (2).(b) Remove the intake manifold mounting bolts, then remove the intake manifold (3) and the gasket (4). When refitting the manifolds, fit each gasket with the side marked "MANIFOLD" facing the manifold. (4) Removing Water PumpRemove the water pump mounting bolts, then remove the water pump (1). (5) Removing Alternator(a) Disconnect the battery cables.(b) Disconnect the lead from terminal B at the rear of the alternator.(c) Remove the alternator connector.(d) Loosen the alternator brace bolt (1) and support bolt (2), then push the alternator toward the engine and remove the fan belt.(e) Remove the alternator. (6) Removing Starter(a) Disconnect the battery's (-) and (+) terminals in that sequence.(b) Disconnect the start wiring (1).(c) Remove the starter's two mounting bolts (2), then remove the starter (3). (7) Removing Oil Filter(a) The oil filter (2) must be replaced every 100 hours of use.(b) Remove the oil filter using a filter wrench (1). (8) Removing Fuel Filter(a) Remove the fuel pipe (1) that leads from the fuel tank and the fuel pipe (2) that leads to the fuel pump.(b) Remove the fuel filter (3) from the engine. (9) Removing Fuel Pipes(a) Remove the clamps from the four fuel pipes (1), then disconnect the fuel pipes from the engine and from the injection pump.(b) Remove the joints and clips from the fuel hose (2), then disconnect the fuel hose from the injector holders.

To keep dirt out of the fuel system, fit rubber caps over the parts of the injection pump and injector inlet connectors from which the injection pipes are disconnected.

(10) Removing Injection Pump

1 Fuel hose2 Fuel pipe3 Tie rod cover4 Tie rod spring5 Tie rod6 Injection pump7 Adjustment shim8 Control rack pin(a) Remove the tie rod cover (3).

Removing tie rod cover(b) Using long-nosed pliers, remove the tie rod spring (4) from the control rack pin (8) and from the governor lever pin.(c) Remove the tie rod (5).

Removing tie rod(d) Remove the injection pump (6) and the adjustment shim (7).

Removing injection pump(11) Removing Oil PumpRemove the oil pump's four mounting bolts, then remove the oil pump (1). (12) Removing InjectorDisconnect the fuel injection pipe (1) and the fuel hose (2) before removing the injector (3). 3. Refitting Accessories

3.1 General PointsRefit accessories by following the removal procedures in reverse. After refitting accessories, perform the following operations:(1) Pour the specified amount of engine oil into the engine.(2) Pour coolant into the cooling

Have questions with 106971-0600?

Group cross 106971-0600 ZEXEL

106971-0600

INJECTION-PUMP ASSEMBLY