Information injection-pump assembly

BOSCH

9 400 618 637

9400618637

ZEXEL

106971-0584

1069710584

NISSAN-DIESEL

1671397105

1671397105

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

4317943 Refrigerator Ice Maker Replacement for Kenmore/Sears 106.9710584 - Compatible with W10190952 Icemaker

UpStart Components UpStart Components Replacement 4317943 Refrigerator Ice Maker for Kenmore / Sears 106.9710584 || Ultra durable, high quality material resists wear and tear over time. Easy at-home installation. || An affordable way to extend the life of your machine. || Please make sure to check your original part to confirm that you are buying the correct product. || Compatible W10190952 Icemaker for Part Number 4317943, AP2984633, 4317943R, 4317943VP, 46000978556, 46004211173, AH358591, EA358591, ER4317943, J21791, J22241, M626687, PS358591, RIM943, TJ90RIM943, W10122496, W10190952, W10281545, W10632400

UpStart Components UpStart Components Replacement 4317943 Refrigerator Ice Maker for Kenmore / Sears 106.9710584 || Ultra durable, high quality material resists wear and tear over time. Easy at-home installation. || An affordable way to extend the life of your machine. || Please make sure to check your original part to confirm that you are buying the correct product. || Compatible W10190952 Icemaker for Part Number 4317943, AP2984633, 4317943R, 4317943VP, 46000978556, 46004211173, AH358591, EA358591, ER4317943, J21791, J22241, M626687, PS358591, RIM943, TJ90RIM943, W10122496, W10190952, W10281545, W10632400

Service parts 106971-0584 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660097064

12.

Open Pre:MPa(Kqf/cm2)

14.7(150)/21.6(220)

15.

NOZZLE SET

Include in #1:

106971-0584

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 618 637

9400618637

ZEXEL

106971-0584

1069710584

NISSAN-DIESEL

1671397105

1671397105

Zexel num

Bosch num

Firm num

Name

106971-0584

9 400 618 637

1671397105 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RF10 * K

RF10 * K

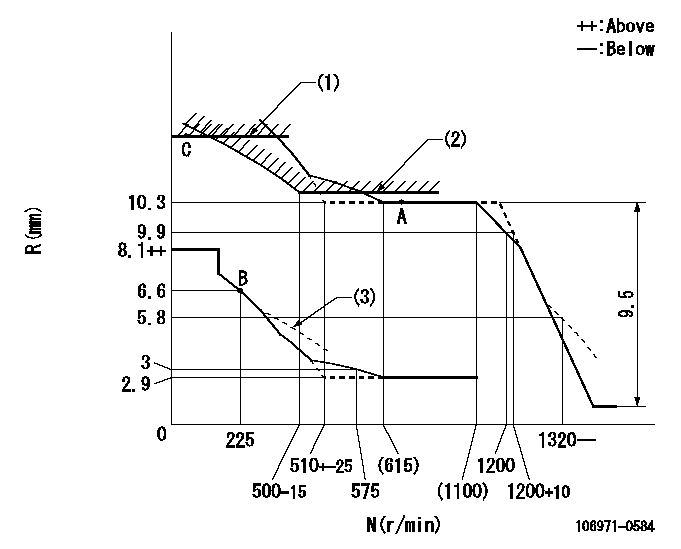

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

132.4

131.4

133.4

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.6

11.6

15.6

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.8+0.2

Pump speed

r/min

40

40

40

Average injection quantity

mm3/st.

115

105

125

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Load

3/4

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4

3.5

4.5

Load

4/4

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

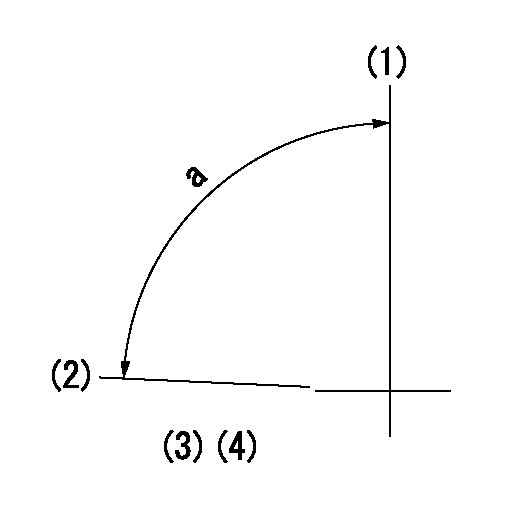

(1)Rack limit using the stop lever: R1

(2)Excess fuel setting for starting: SXL

(3)Damper spring setting: DL

----------

R1=11.8+0.2mm SXL=10.3+0.2mm DL=6.1-0.2mm

----------

----------

R1=11.8+0.2mm SXL=10.3+0.2mm DL=6.1-0.2mm

----------

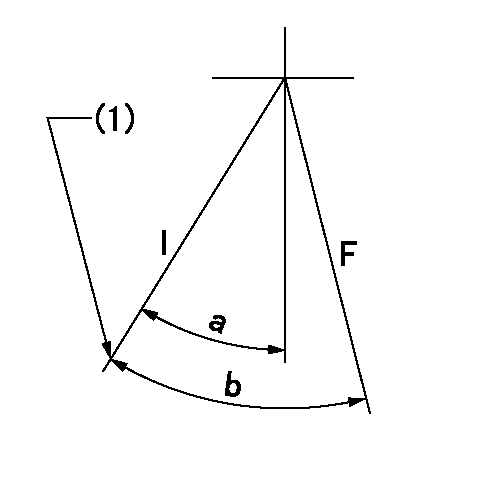

Speed control lever angle

F:Full speed

----------

----------

a=8deg+-5deg

----------

----------

a=8deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=18.5deg+-5deg b=27.5deg+-3deg

----------

----------

a=18.5deg+-5deg b=27.5deg+-3deg

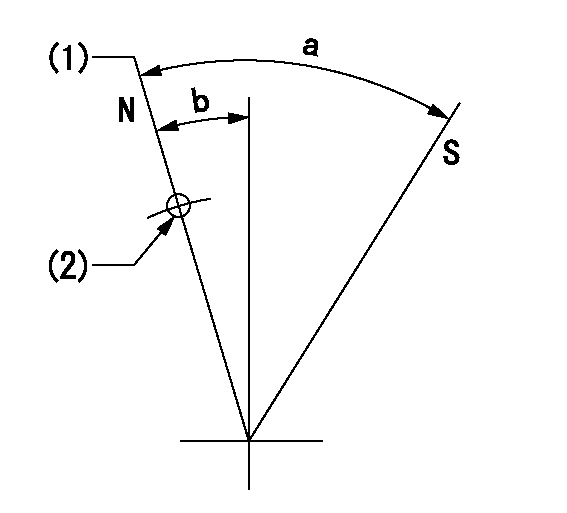

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the hole at R = bb

----------

aa=11.8+0.2mm bb=32mm

----------

a=30.5deg+-5deg b=5deg+-5deg

----------

aa=11.8+0.2mm bb=32mm

----------

a=30.5deg+-5deg b=5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

1. Overview

1.1 External Views 1.2 Engine Model and Engine Serial Number(1) The engine model code is embossed next to the injection pump on the right-hand side of the cylinder block.

Engine model and total displacement(2) The engine serial number is shown by a label attached to the top of the rocker cover. It is also stamped on the injection pump mounting surface of the cylinder block.(3) The engine serial number is stamped as shown below:

Location of engine serial number label1.3 Engine Model and Application Codes(1) The engine model code is designated as shown below.* Engine model and classification * Model code 2. Specifications

2.1 Major Specifications 3. Points to Note for Disassembly and Reassembly

This service manual contains recommended service procedures for your Mitsubishi diesel engine. It also contains information on special tools and basic safety precautions. Since hazards exist in many places, the safety precautions in this manual should not be considered exhaustive. It is your responsibility to exercise common sense and to pay attention to safety at all times.Always perform service operations in accordance with this manual. When performing disassembly and reassembly operations, also observe the general instructions given below.3.1 Disassembly(1) Use only the correct tools and instruments.(2) Use an overhaul stand or work bench if necessary, and make ready a surface where removed parts can be arranged. Remove parts in the specified disassembly sequence.(3) Arrange disassembled parts neatly to avoid losing them.(4) Pay attention to alignment and position marks. If necessary, make your own marks to facilitate reassembly.(5) Carefully check parts for abnormalities when removing or cleaning them. Abnormalities may be harder to see after parts have been removed or cleaned.(6) Strive to ensure safety at all times. It is particularly important to make sure that items being disassembled are properly balanced and to pay attention to safety when moving heavy items. Use jacks and chain blocks when necessary.3.2 Reassembly(1) Wash all engine parts (except oil seals, O-rings, and rubber seals) in cleaning solvent and dry them with compressed air.(2) Use only the correct tools and instruments.(3) Use only high-quality oils and greases of the specified types. Be sure to apply a coat of oil, grease, or sealant wherever specified.(4) Use a torque wrench to achieve all specified tightening torques.(5) As a general rule, all gaskets and seals must be replaced with new ones. Apply adhesive where required, and be careful not to apply too much.

1.1 External Views 1.2 Engine Model and Engine Serial Number(1) The engine model code is embossed next to the injection pump on the right-hand side of the cylinder block.

Engine model and total displacement(2) The engine serial number is shown by a label attached to the top of the rocker cover. It is also stamped on the injection pump mounting surface of the cylinder block.(3) The engine serial number is stamped as shown below:

Location of engine serial number label1.3 Engine Model and Application Codes(1) The engine model code is designated as shown below.* Engine model and classification * Model code 2. Specifications

2.1 Major Specifications 3. Points to Note for Disassembly and Reassembly

This service manual contains recommended service procedures for your Mitsubishi diesel engine. It also contains information on special tools and basic safety precautions. Since hazards exist in many places, the safety precautions in this manual should not be considered exhaustive. It is your responsibility to exercise common sense and to pay attention to safety at all times.Always perform service operations in accordance with this manual. When performing disassembly and reassembly operations, also observe the general instructions given below.3.1 Disassembly(1) Use only the correct tools and instruments.(2) Use an overhaul stand or work bench if necessary, and make ready a surface where removed parts can be arranged. Remove parts in the specified disassembly sequence.(3) Arrange disassembled parts neatly to avoid losing them.(4) Pay attention to alignment and position marks. If necessary, make your own marks to facilitate reassembly.(5) Carefully check parts for abnormalities when removing or cleaning them. Abnormalities may be harder to see after parts have been removed or cleaned.(6) Strive to ensure safety at all times. It is particularly important to make sure that items being disassembled are properly balanced and to pay attention to safety when moving heavy items. Use jacks and chain blocks when necessary.3.2 Reassembly(1) Wash all engine parts (except oil seals, O-rings, and rubber seals) in cleaning solvent and dry them with compressed air.(2) Use only the correct tools and instruments.(3) Use only high-quality oils and greases of the specified types. Be sure to apply a coat of oil, grease, or sealant wherever specified.(4) Use a torque wrench to achieve all specified tightening torques.(5) As a general rule, all gaskets and seals must be replaced with new ones. Apply adhesive where required, and be careful not to apply too much.

Have questions with 106971-0584?

Group cross 106971-0584 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106971-0584

9 400 618 637

1671397105

INJECTION-PUMP ASSEMBLY

RF10

RF10