Information injection-pump assembly

ZEXEL

106971-0550

1069710550

Rating:

Service parts 106971-0550 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Include in #1:

106971-0550

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106971-0550

1069710550

Zexel num

Bosch num

Firm num

Name

106971-0550

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.2

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

105.2

104.2

106.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.7+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

11.9

9.9

13.9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

600--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

550

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1

0.5

1.5

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

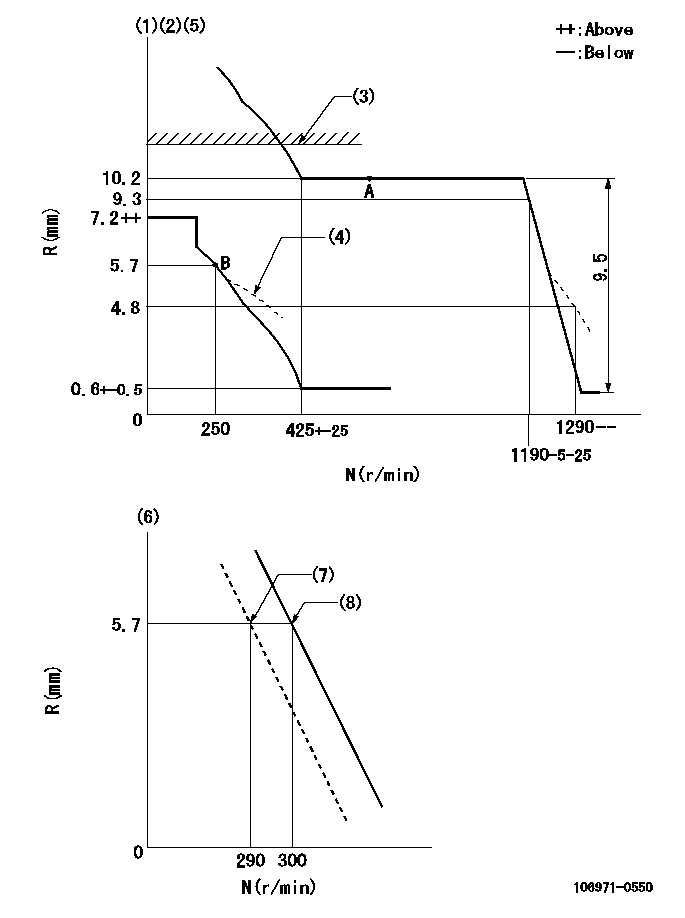

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Rack limit using the stop lever: R1

(4)Damper spring setting: DL

(5)Adjust at stop lever rack limit N = N1.

(6)Variable speed specification: idling adjustment

(7)Main spring setting

(8)Set idle sub-spring

----------

RT=1 TH=2.6mm R1=10.6+0.2mm DL=5.7-0.2mm N1=100r/min

----------

----------

RT=1 TH=2.6mm R1=10.6+0.2mm DL=5.7-0.2mm N1=100r/min

----------

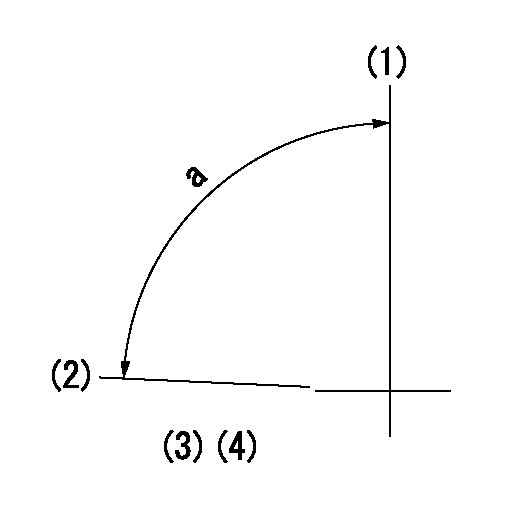

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=9.5deg+-5deg b=19.5deg+-5deg

----------

----------

a=9.5deg+-5deg b=19.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=35.5deg+-3deg

----------

----------

a=24.5deg+-5deg b=35.5deg+-3deg

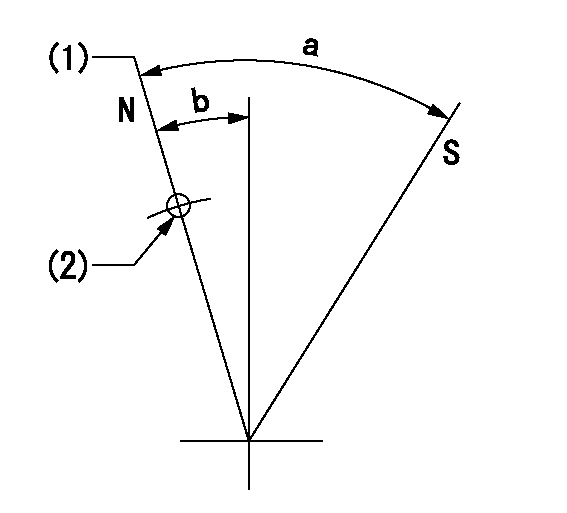

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the hole at R = bb

----------

aa=10.6+0.2mm bb=32mm

----------

a=27.5deg+-5deg b=2deg+-5deg

----------

aa=10.6+0.2mm bb=32mm

----------

a=27.5deg+-5deg b=2deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

1. Exploded viewsIn the exploded views, the component parts are separated but so arranged to show their relationship to the whole. Index numbering is used to identify the parts and to indicate a sequence in which the parts are to be removed for disassembly, or they are to be installed for assembly. 2. SymbolsThe following symbols are used in this manual to emphasize important and critical instructions:

Indicates a condition that is essential to highlight.

Indicates a condition that can cause engine damage.

Indicates a condition that can cause personal injury or death.3. Definition of locational termsThe fan end is "front" and the flywheel end is "rear". The words "left" and "right" are as these directions would appear from the flywheel end.4. Dimensional or specification termsNominal size...Is the named size which has no specified limits of accuracy.Standard...Is the dimension of a part to be attained at the time of assembly, or the standard performance.Limit...Is the maximum or minimum permissible limit beyond which a part must be repaired or replaced.5. Tightening torquesTighten bolts, nuts, etc. in a wet condition (apply oil to threads) when specified as [WET]. Tighten them in a dry condition unless so specified. Use the general torques unless otherwise specified.MODEL IDENTIFICATION AND SERIAL NUMBER LOCATION

1. Model identification location(a) The model identification is embossed on the right side of the cylinder block, near the fuel injection pump mount.(b) The model identifications and displacements of the engines in current production are as listed below:

Model identification location(c) A scheme of coding used for identifying the engines in current production is as follows:

Example: Coded designation2. Serial Number LocationThe serial number is punched on the cylinder block, near the fuel injection pump mount.

Serial number locationCOMPONENT LOCATION

S3L/S3L2 S4L/S4L2SPECIFICATIONS

PERFORMANCE CURVES (ONE-HOUR RATING, WITH FAN)

PRIME POWER OUTPUT CHART

Indicates a condition that is essential to highlight.

Indicates a condition that can cause engine damage.

Indicates a condition that can cause personal injury or death.3. Definition of locational termsThe fan end is "front" and the flywheel end is "rear". The words "left" and "right" are as these directions would appear from the flywheel end.4. Dimensional or specification termsNominal size...Is the named size which has no specified limits of accuracy.Standard...Is the dimension of a part to be attained at the time of assembly, or the standard performance.Limit...Is the maximum or minimum permissible limit beyond which a part must be repaired or replaced.5. Tightening torquesTighten bolts, nuts, etc. in a wet condition (apply oil to threads) when specified as [WET]. Tighten them in a dry condition unless so specified. Use the general torques unless otherwise specified.MODEL IDENTIFICATION AND SERIAL NUMBER LOCATION

1. Model identification location(a) The model identification is embossed on the right side of the cylinder block, near the fuel injection pump mount.(b) The model identifications and displacements of the engines in current production are as listed below:

Model identification location(c) A scheme of coding used for identifying the engines in current production is as follows:

Example: Coded designation2. Serial Number LocationThe serial number is punched on the cylinder block, near the fuel injection pump mount.

Serial number locationCOMPONENT LOCATION

S3L/S3L2 S4L/S4L2SPECIFICATIONS

PERFORMANCE CURVES (ONE-HOUR RATING, WITH FAN)

PRIME POWER OUTPUT CHART

Have questions with 106971-0550?

Group cross 106971-0550 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106971-0550

INJECTION-PUMP ASSEMBLY