Information injection-pump assembly

ZEXEL

106971-0500

1069710500

Rating:

Service parts 106971-0500 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97064

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

15.

NOZZLE SET

Include in #1:

106971-0500

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106971-0500

1069710500

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

132.4

131.4

133.4

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13.6

11.6

15.6

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Load

3/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Load

3/4

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

4

3.5

4.5

Load

4/4

Remarks

Finish

Finish

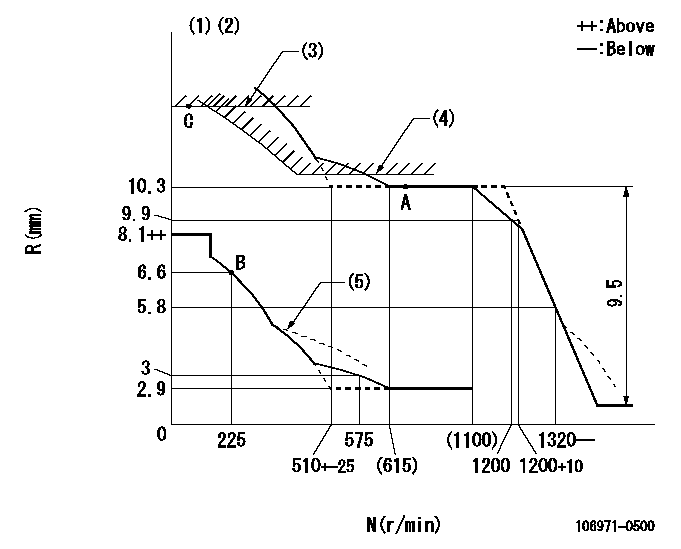

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Rack limit using the stop lever: R1

(4)Excess fuel setting for starting: SXL

(5)Damper spring setting: DL

----------

RT=1 TH=1.6mm R1=11.8+0.2mm SXL=10.3+0.2mm DL=5.6-0.2mm

----------

----------

RT=1 TH=1.6mm R1=11.8+0.2mm SXL=10.3+0.2mm DL=5.6-0.2mm

----------

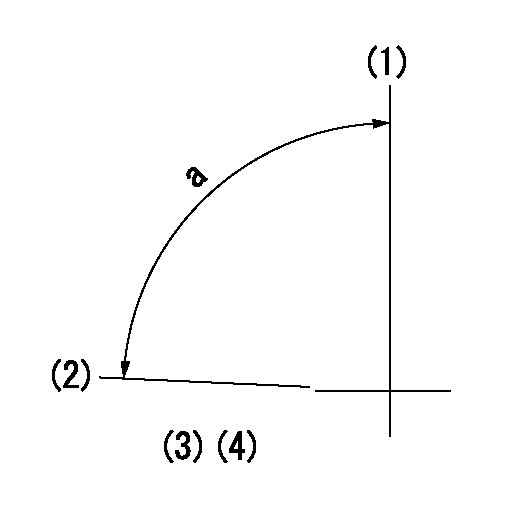

Speed control lever angle

F:Full speed

----------

----------

a=8deg+-5deg

----------

----------

a=8deg+-5deg

0000000901

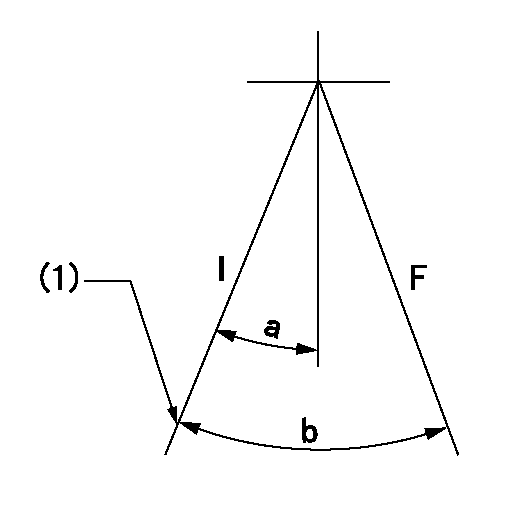

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=18.5deg+-5deg b=27.5deg+-3deg

----------

----------

a=18.5deg+-5deg b=27.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

----------

aa=11.8+0.2mm

----------

a=5deg+-5deg b=30.5deg+-5deg

----------

aa=11.8+0.2mm

----------

a=5deg+-5deg b=30.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

Thermostat Removal

Stop engine.Disconnect negative (-) battery cable at battery.

Do not drain engine coolant until the coolant temperature is below operating temperature. Then loosen drain cock slowly to relieve any excess pressure.

Remove coolant from cooling system.

Fig. 1-Thermostat CoverDisconnect upper radiator hose from thermostat cover (Fig. 1).Remove thermostat cover.Remove gasket.

Fig. 2-ThermostatLift thermostat (Fig. 2) out of thermostat housing.Repair

Fig. 3-Thermostat OpenIf engine is running too hot or too cold inspect thermostat for defects. Test in hot water for proper opening and closing.Installation

Some thermostats are marked "TO RAD", "THIS SIDE TOWARD RADIATOR", or "TOWARD RADIATOR" to indicate the top side. Put thermostat in housing so that top side is toward thermostat cover.

Fig. 4-Top SideIf thermostat is not marked, find the top side (Fig. 4). Put thermostat in housing so that top side is toward thermostat cover.

Fig. 5-Cap ScrewUsing a new gasket, install thermostat cover. Put cap screws (Fig. 5) through thermostat cover into thermostat housing. Tighten cap screws to 35 lb-ft (47 N m) (5 kg-m).Connect upper radiator hose to thermostat cover.Fill cooling system to proper level with proper coolant.Connect negative (-) battery cable to battery negative (-) terminal.Start engine.Check for leaks at hose connection and around gasket area.

Stop engine.Disconnect negative (-) battery cable at battery.

Do not drain engine coolant until the coolant temperature is below operating temperature. Then loosen drain cock slowly to relieve any excess pressure.

Remove coolant from cooling system.

Fig. 1-Thermostat CoverDisconnect upper radiator hose from thermostat cover (Fig. 1).Remove thermostat cover.Remove gasket.

Fig. 2-ThermostatLift thermostat (Fig. 2) out of thermostat housing.Repair

Fig. 3-Thermostat OpenIf engine is running too hot or too cold inspect thermostat for defects. Test in hot water for proper opening and closing.Installation

Some thermostats are marked "TO RAD", "THIS SIDE TOWARD RADIATOR", or "TOWARD RADIATOR" to indicate the top side. Put thermostat in housing so that top side is toward thermostat cover.

Fig. 4-Top SideIf thermostat is not marked, find the top side (Fig. 4). Put thermostat in housing so that top side is toward thermostat cover.

Fig. 5-Cap ScrewUsing a new gasket, install thermostat cover. Put cap screws (Fig. 5) through thermostat cover into thermostat housing. Tighten cap screws to 35 lb-ft (47 N m) (5 kg-m).Connect upper radiator hose to thermostat cover.Fill cooling system to proper level with proper coolant.Connect negative (-) battery cable to battery negative (-) terminal.Start engine.Check for leaks at hose connection and around gasket area.