Information injection-pump assembly

BOSCH

9 400 618 623

9400618623

ZEXEL

106971-0373

1069710373

NISSAN-DIESEL

1671397076

1671397076

Rating:

Cross reference number

BOSCH

9 400 618 623

9400618623

ZEXEL

106971-0373

1069710373

NISSAN-DIESEL

1671397076

1671397076

Zexel num

Bosch num

Firm num

Name

106971-0373

9 400 618 623

1671397076 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RE10 * K

RE10 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

105.2

104.2

106.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

12.9

10.9

14.9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

950

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

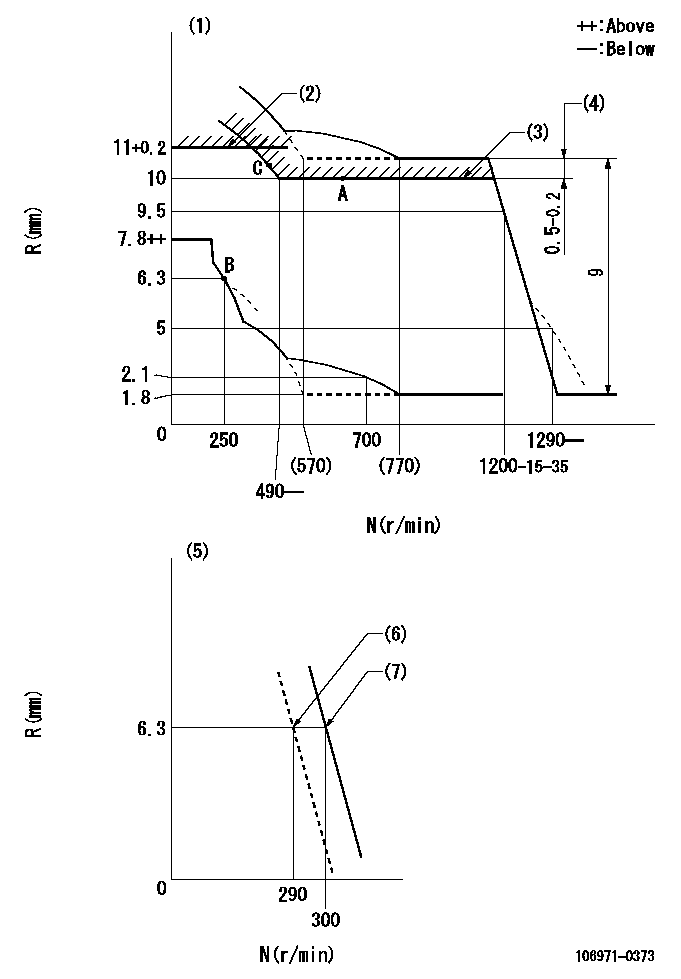

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)Rack limit using stop lever (at N = N1 or less).

(3)Excess fuel setting for starting

(4)At pump speed N2

(5)Variable speed specification: idling adjustment

(6)Main spring setting

(7)Set idle sub-spring

----------

DL=6.3-0.2mm N1=100r/min N2=1100r/min

----------

----------

DL=6.3-0.2mm N1=100r/min N2=1100r/min

----------

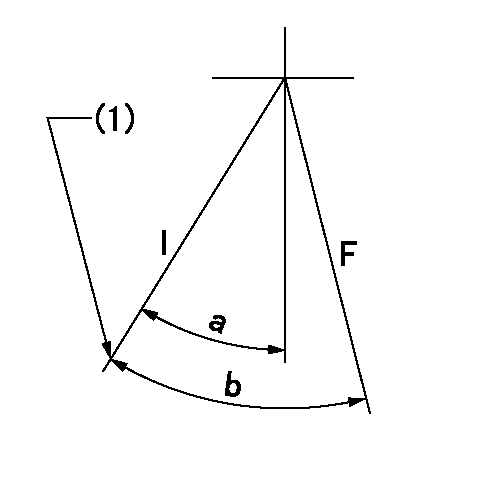

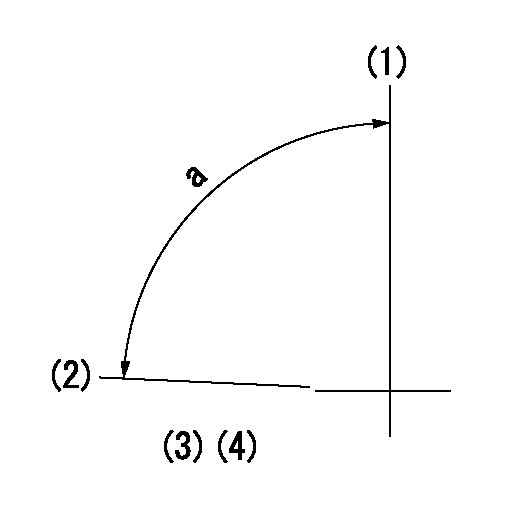

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(10deg)+-5deg b=(22deg)+-5deg

----------

----------

a=(10deg)+-5deg b=(22deg)+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=31deg+-3deg

----------

----------

a=24.5deg+-5deg b=31deg+-3deg

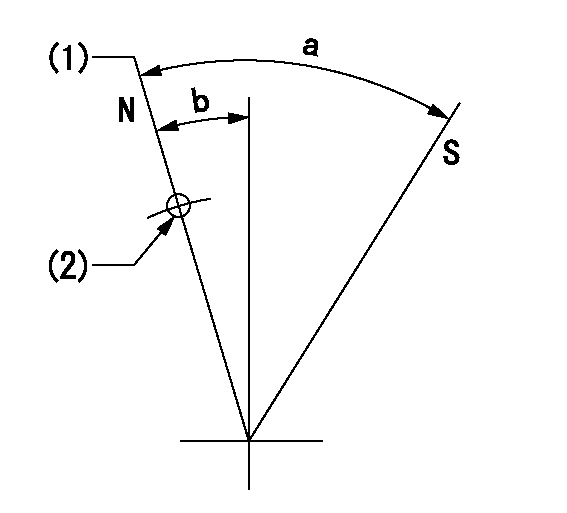

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the hole at R = bb

----------

aa=11+0.2mm bb=32mm

----------

a=28.5deg+-5deg b=3deg+-5deg

----------

aa=11+0.2mm bb=32mm

----------

a=28.5deg+-5deg b=3deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

REM07-31

Reman

October 2007PRODUCT LINE ADDITION: REMANUFACTURED FUEL INJECTORS FOR VARIOUS INDUSTRIAL, MACHINE, AND MARINE ENGINE APPLICATIONS AnnouncementThe Caterpillar Remanufactured Products Group announces the expansion of the remanufactured injector product line to include coverage for various C7, C9, and 3306 industrial, machine, and marine applications. CoverageThe introduction of these injectors provides dealers with an additional, lower cost repair option for various C7, C9, and 3306 engine applications. Refer to the tables below for model usage. Features and BenefitsCat? Remanufactured injectors offer excellent value to customers. Customers who want fast repair turn-around, superior quality and reliability, and lower repair costs will benefit from the use of these Remanufactured injectors by providing immediate, off-the-shelf availability at a fraction of the new price. Core Acceptance Core Acceptance Crietira for Catperillar Remanufactured injectors is simple. Full core credit is issued when the core is fully assembled, there is no excessive rust or non-operational damage and it is an acceptable part number. Consult your Core Acceptance Guide for complete details.WarrantyPlease consult the appropriate warranty statement for your area.

PELJ0827 CATERPILLAR? ?2007 Caterpillar

Have questions with 106971-0373?

Group cross 106971-0373 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106971-0373

9 400 618 623

1671397076

INJECTION-PUMP ASSEMBLY

RE10

RE10