Information injection-pump assembly

ZEXEL

106971-0330

1069710330

NISSAN-DIESEL

1671397074

1671397074

Rating:

Service parts 106971-0330 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97019

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106971-0330

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106971-0330

1069710330

NISSAN-DIESEL

1671397074

1671397074

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

107.2

106.2

108.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.7+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

11.9

9.9

13.9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

800--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

950

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

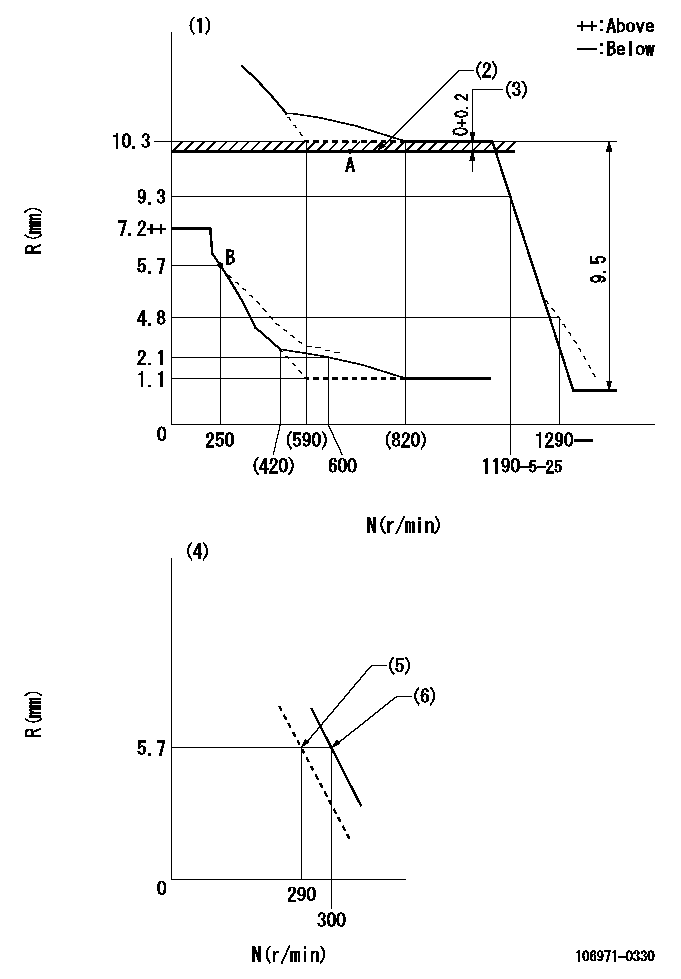

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)Rack limit using stop lever

(3)At pump speed N1

(4)Variable speed specification: idling adjustment

(5)Main spring setting

(6)Set idle sub-spring

----------

DL=5.7-0.2mm N1=1150r/min

----------

----------

DL=5.7-0.2mm N1=1150r/min

----------

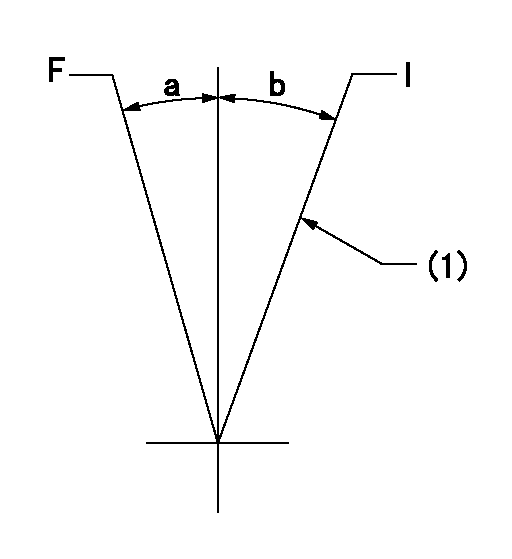

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(9.5deg)+-5deg b=10deg+-5deg

----------

----------

a=(9.5deg)+-5deg b=10deg+-5deg

0000000901

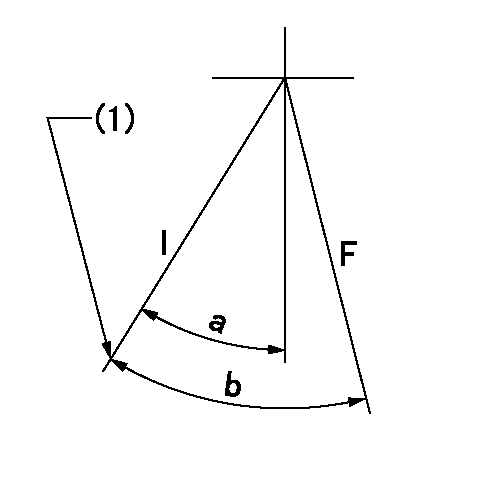

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=34deg+-3deg

----------

----------

a=24.5deg+-5deg b=34deg+-3deg

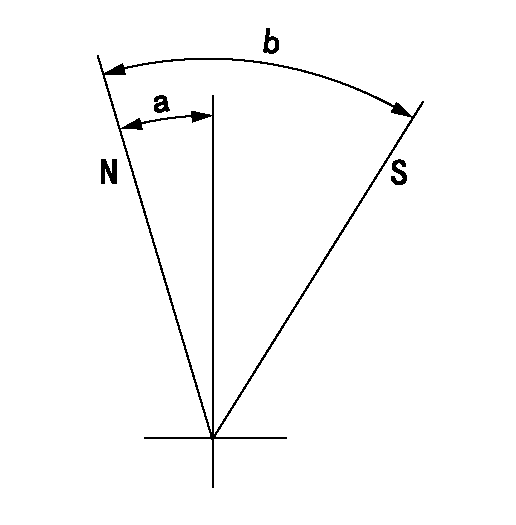

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=1.5deg+-5deg b=30.5deg+-5deg

----------

----------

a=1.5deg+-5deg b=30.5deg+-5deg

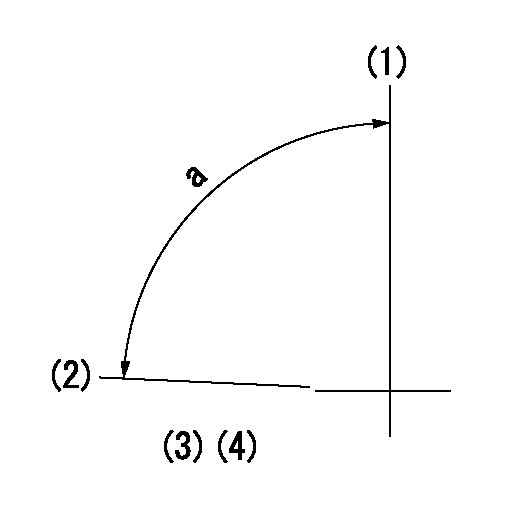

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

Use of the convenient tip (measure) and pour container allows accurate dilution in all sizes of equipment. 1 ounce of Caterpillar Diesel Fuel Conditioner treats 11 gallons of diesel fuel (one 32-ounce container will treat 350 gallons of diesel fuel).

The conditioner comes in a case of six 32-ounce containers.

As sulfur restrictions become more stringent, Caterpillar

?

Diesel Fuel Conditioner will help compensate for reduced lubricity found in some low sulfur diesel fuels. It will also improve combustion, fuel storage stability, and fuel system life.

Gary Coker

Product Support Division

Product Support

(309)578-8249

Coker_Gary_D

PELJ0525 CATERPILLAR? ?2005 Caterpillar