Information injection-pump assembly

ZEXEL

106971-0261

1069710261

Rating:

Service parts 106971-0261 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Include in #1:

106971-0261

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106971-0261

1069710261

Zexel num

Bosch num

Firm num

Name

106971-0261

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

107.2

106.2

108.2

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.7+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

11.9

9.9

13.9

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

600--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

550

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1

0.5

1.5

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

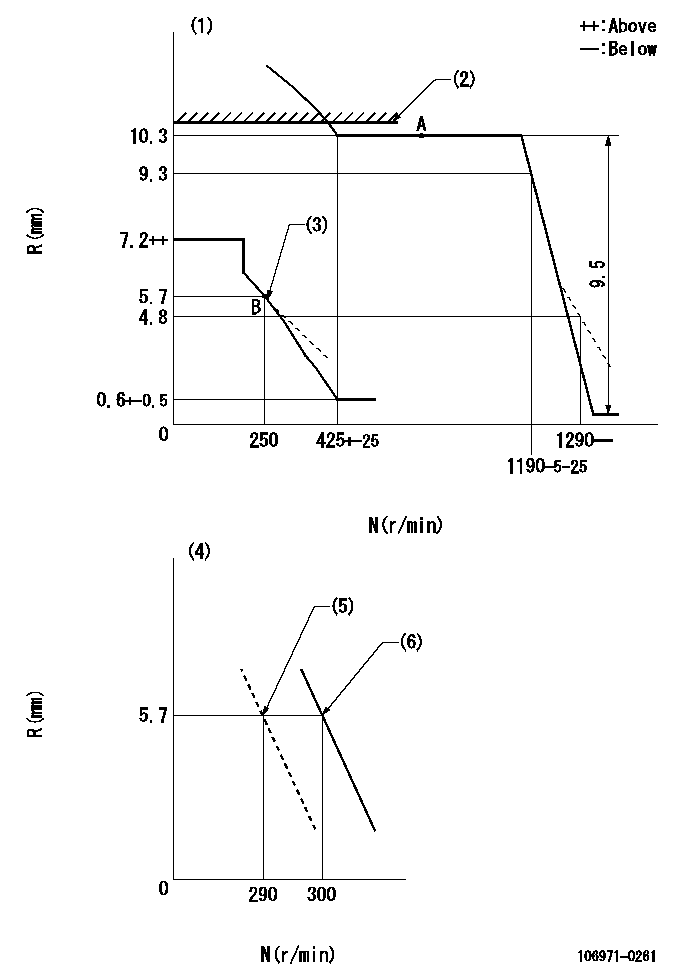

Test data Ex:

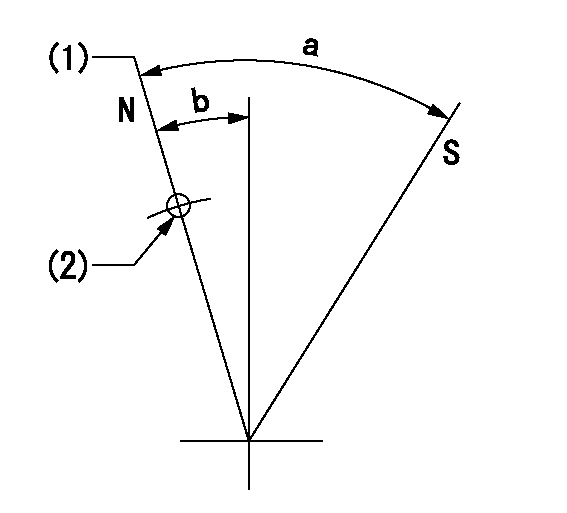

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Rack limit using the stop lever: R1

(3)Damper spring setting

(4)Variable speed specification: idling adjustment

(5)Main spring setting

(6)Set idle sub-spring

----------

DL=5.7-0.2mm R1=10.6+0.2mm

----------

----------

DL=5.7-0.2mm R1=10.6+0.2mm

----------

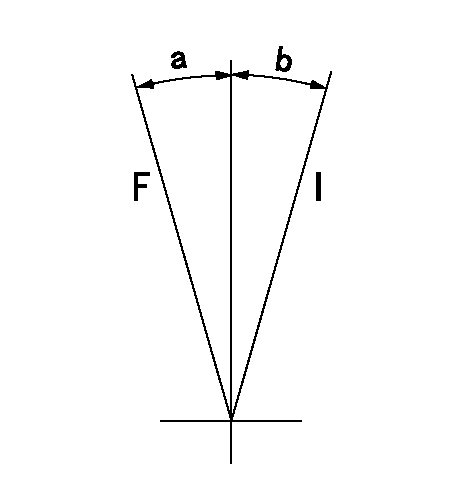

Speed control lever angle

F:Full speed

I:Idle

----------

----------

a=9.5deg+-5deg b=10deg+-5deg

----------

----------

a=9.5deg+-5deg b=10deg+-5deg

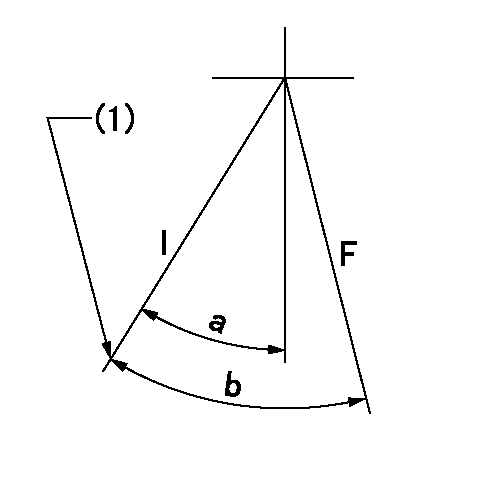

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24.5deg+-5deg b=33deg+-3deg

----------

----------

a=24.5deg+-5deg b=33deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the hole at R = bb

----------

aa=10.6+0.2mm bb=32mm

----------

a=27.5deg+-5deg b=2deg+-5deg

----------

aa=10.6+0.2mm bb=32mm

----------

a=27.5deg+-5deg b=2deg+-5deg

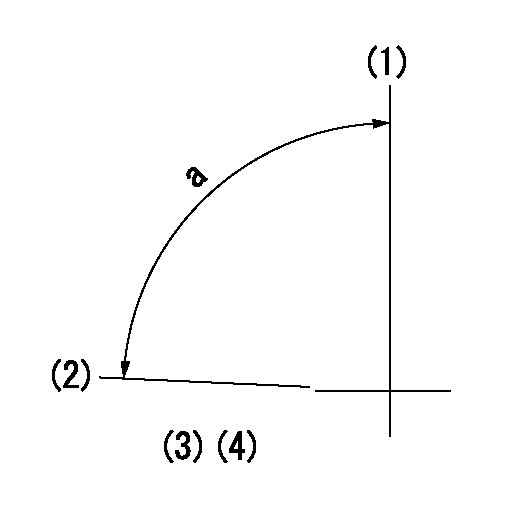

Timing setting

(1)Pump vertical direction

(2)Position of the coupling's key groove at the start of injection for the No. 10 cylinder.

(3)-

(4)-

----------

----------

a=(90deg)

----------

----------

a=(90deg)

Information:

Features and Benefits

Reman short blocks expand the repair options available. When used with other

remanufactured products and reusable components from the core engine, short blocks help

lower dealer repair/rebuild cost and shorten turnaround time.

The 3500B short block is a fully assembled cylinder block with sequence valves, crankshaft,

cylinder pack groups, piston jets, camshaft bearings, and lifting eyes.

The short block does not include camshaft, cam access covers, or block side covers. The

short block may contain a remanufactured cylinder block, crankshaft, connecting rods, and

pistons. The cylinder liners, piston rings, camshaft bearings, and crankshaft bearings are

100% new components. The remanufactured components are remanufactured to factory

specifications using factory precision machine tools and proven processes.

Core Acceptance

Short blocks from 3500B diesel series machine and commercial engines that were built with

101-0829 Piston ? Rod Gp. are acceptable as core. Reference SELD0026 for the latest Short

Block Core Acceptance Criteria.

Core Management

Please refer to the Caterpillar Core Management Information System (CMIS 2) Parts

Information application describing all reman part/CAF and related information. Also refer to

other CMIS 2 inquiry applications such as Customer Profiles, Inspection Reason Codes,

Inspection Line Inquiry, Add Charge Information, Entitlement Activity, Entitlement Inquiry,

CCR Inquiry, CCR Entry, Shipment Processing; Process Packaging Grief; and Reporting to

properly manage core returns and monitor inspection performance. This information will be

available to all dealers worldwide after your CMIS 2 conversion date. In the meantime,

please continue to use the current CMIS Entitlement Parts Inquiry Screen describing the list

of parts in a Core Acceptability Family (CAF) and related part number detail.

For the latest updates of Reman Policies and Core Management (SELD0122), Core

Management Systems & Operations Procedures (SELD0040), and Shipping Instructions

(SELD0039), go to the Reman website and click on Procedures and Policies (listed under

Reman Program Information).

Please note that 3500B short block core will be shipped to Lafayette address:

Caterpillar Inc.

3701 State Road 26 East

Lafayette, Indiana, 47905

U.S.A.

See "SHIPPING INSTRUCTIONS" (SELD0039) for more information.

If you have any questions regarding core return processing, feel free to call Corinth toll free

at (800) 537-2928. For assistance with technical questions, call the Peoria Reman

Customer Satisfaction Hot Line also toll free at (888) 88-REMAN or use our E-mail

address--Reman_Help.

James E. Reynolds

Dept: 3500 Reman Engines

Location: 88-B21L

Phone: 765-448-2295

Fax: 765-448-5897

Have questions with 106971-0261?

Group cross 106971-0261 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106971-0261

INJECTION-PUMP ASSEMBLY