Information injection-pump assembly

ZEXEL

106971-0221

1069710221

NISSAN-DIESEL

1679097014

1679097014

Rating:

Service parts 106971-0221 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

22.6(230)

15.

NOZZLE SET

Include in #1:

106971-0221

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106971-0221

1069710221

NISSAN-DIESEL

1679097014

1679097014

Zexel num

Bosch num

Firm num

Name

106971-0221

1679097014 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

RD10T06 * K

RD10T06 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

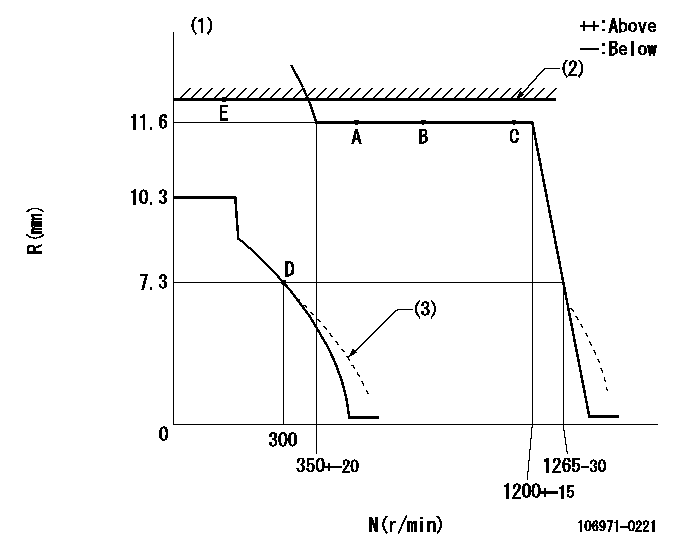

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

128.9

122.9

134.9

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.6

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

131.5

125.5

137.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.6

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

125

123

127

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7.3+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

17.8

15.8

19.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

300+100

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

3.4

2.9

3.9

Timer adjustment_04

Pump speed

r/min

1250+50

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)Damper spring setting: DL

----------

K=9 RAL=12.4+-0.1mm DL=6.8-0.2mm

----------

----------

K=9 RAL=12.4+-0.1mm DL=6.8-0.2mm

----------

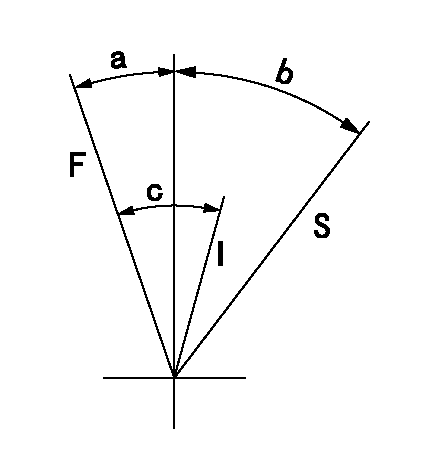

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=9deg+-5deg b=32deg+-3deg c=30deg+-5deg

----------

----------

a=9deg+-5deg b=32deg+-3deg c=30deg+-5deg

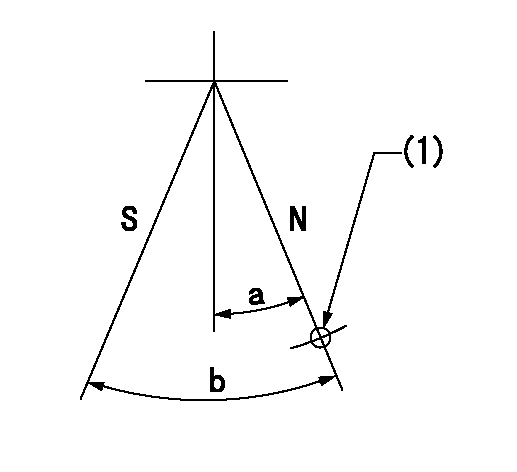

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the hole at R = aa

----------

aa=55mm

----------

a=27deg+-5deg b=53deg+-5deg

----------

aa=55mm

----------

a=27deg+-5deg b=53deg+-5deg

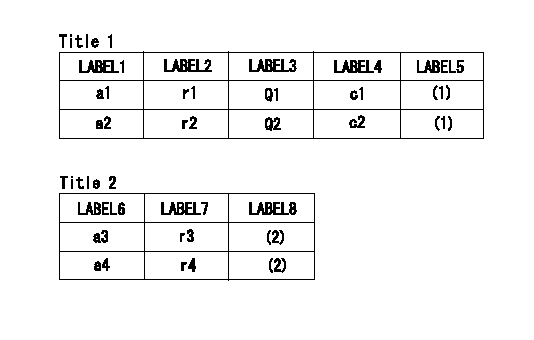

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=M a2=F r1=1150r/min r2=1150r/min Q1=125+-2mm3/st Q2=115+-2mm3/st c1=+-4% c2=+-4% a3=M a4=F r3=1185r/min r4=1150r/min

----------

----------

a1=M a2=F r1=1150r/min r2=1150r/min Q1=125+-2mm3/st Q2=115+-2mm3/st c1=+-4% c2=+-4% a3=M a4=F r3=1185r/min r4=1150r/min

Information:

Operations that may cause product damage are identified by notice labels in this publication.

Introduction

This Tool Operating Manual contains two filter installation procedures. This first procedure is for installing a primary filter system. This is a coarse filter and will protect the transfer pump from contamination in the oil. The second procedure outlines installing a secondary filter which is designed to protect injection pumps from contaminated oil. Fuel injection pumps used on the 3208 Engine are one example of a fuel injection pump that requires the secondary filter installation.It will be the dealer choice as to which optional filter is installed on the test stand. Determine what type of filtering will be required most often, and install the appropriate type of filtering system. These filters can only be added to the 15 horsepower test stands.Secondary Filter

Nomenclature

Illustration 1. Nomenclature for Secondary Filter Installation. Refer to Chart A for item identification. Fabricated Parts

All the parts required for this installation can be ordered from Caterpillar Parts Distribution, except bracket (1). This must be manufactured by the bench owner, using the dimensions provided below.This bracket can be made from common SAE1018 steel. Weld the two pieces together.

Illustration 2. Filter Mounting Bracket. Refer to Chart B for dimensions. Installation

Assemble the Fuel Filter

1. Install 053-0088 Fitting (17) with 3J-1907 Seal (18) into the inlet port (left side) of the filter base. (This converts a number 6 STOP port to NPT). Install 5P-4455 Fitting (19) into fitting (17).2. Install 2R-6806 Fitting (15) with 3J-1907 Seal (16) into the outlet port (right side) of the filter base.3. Install 6N-4414 Cover (7) onto the filter base using 1P-0436 Gasket (8), 4B-3388/6V-2317 (9), and OS-1616/6V-8490 Bolt (10).4. Install 9S-4182 Plug (5) with 6V-5084 O-ring Seal (6) into the top of the filter base.5. Install the filter base assembly onto filter bracket (1),

Have questions with 106971-0221?

Group cross 106971-0221 ZEXEL

Nissan-Diesel

Nissan-Diesel

106971-0221

1679097014

INJECTION-PUMP ASSEMBLY

RD10T06

RD10T06