Information injection-pump assembly

ZEXEL

106961-1962

1069611962

ISUZU

1156020774

1156020774

Rating:

Service parts 106961-1962 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

19.6(200)

15.

NOZZLE SET

Include in #1:

106961-1962

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1962

1069611962

ISUZU

1156020774

1156020774

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-3520

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-9-8-

5-2-11-1

0-3-6-7-

Pre-stroke

mm

4.4

4.37

4.43

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 15 14.75 15.25

Cal 1-4 deg. 15 14.75 15.25

Difference between angles 2

Cal 1-9 deg. 60 59.75 60.25

Cal 1-9 deg. 60 59.75 60.25

Difference between angles 3

Cal 1-8 deg. 75 74.75 75.25

Cal 1-8 deg. 75 74.75 75.25

Difference between angles 4

Cal 1-5 deg. 120 119.75 120.25

Cal 1-5 deg. 120 119.75 120.25

Difference between angles 5

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 6

Cal 1-11 deg. 180 179.75 180.25

Cal 1-11 deg. 180 179.75 180.25

Difference between angles 7

Cal 1-10 deg. 195 194.75 195.25

Cal 1-10 deg. 195 194.75 195.25

Difference between angles 8

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 9

Cal 1-6 deg. 255 254.75 255.25

Cal 1-6 deg. 255 254.75 255.25

Difference between angles 10

Cal 1-7 deg. 300 299.75 300.25

Cal 1-7 deg. 300 299.75 300.25

Difference between angles 11

Cal 1-12 deg. 315 314.75 315.25

Cal 1-12 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

98

96.5

99.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

D

Rack position

3.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

12.5

11.1

13.9

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Timer adjustment

Pump speed

r/min

500+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1250

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

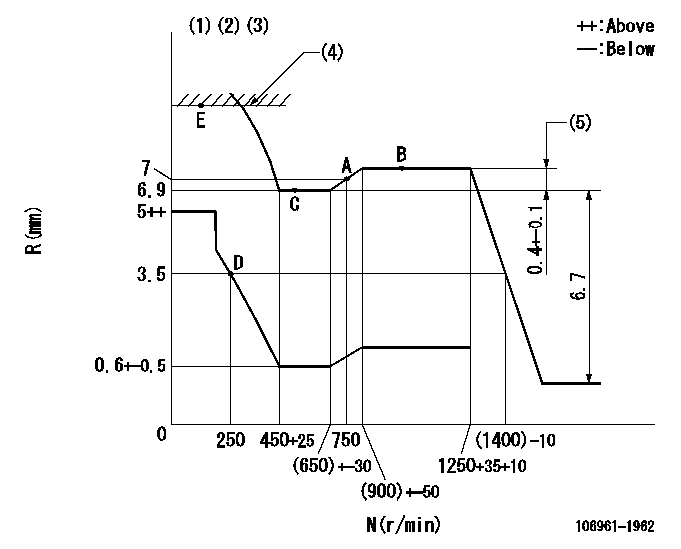

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Damper spring does not operate.

(4)Excess fuel setting for starting: SXL

(5)Rack difference between N = N1 and N = N2

----------

RT=0.8 TH=1.9mm SXL=9.8+0.2mm N1=1250r/min N2=500r/min

----------

----------

RT=0.8 TH=1.9mm SXL=9.8+0.2mm N1=1250r/min N2=500r/min

----------

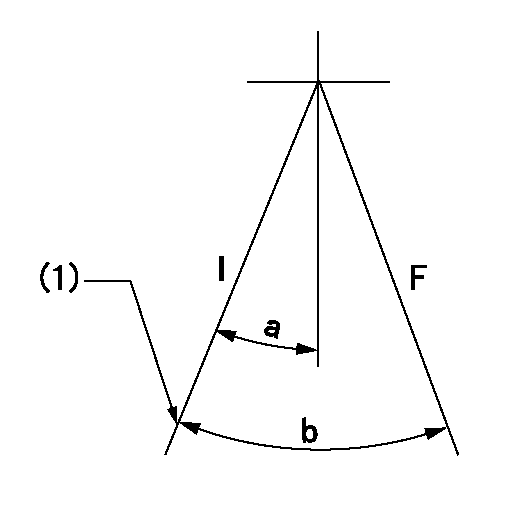

Speed control lever angle

F:Full speed

----------

----------

a=5deg+-5deg

----------

----------

a=5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=33deg+-3deg

----------

----------

a=10deg+-5deg b=33deg+-3deg

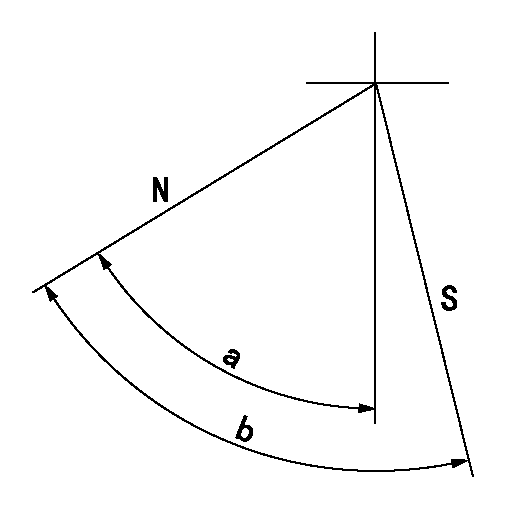

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(170deg)

----------

aa=16deg

----------

a=(170deg)

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.DEF injectors are being replaced in the field and returned to Caterpillar for testing. Results of the testing are finding a large portion of the returned DEF injectors are found to be fault not repeated.This form is to be used and filled out in any case that a DEF injector is being replaced.The DEF injector troubleshooting return form needs to be completed and included within failed part returns documenting what was found that led to DEF injector replacement. Attach the photos of DEF injector tip and mount area along with a Product Status Report to the SIMS claim.References

Table 1

Engine Publication Type Media Number

C7.1 Troubleshooting UENR0668

Testing and Adjusting UENR4467

Disassembly and Assembly UENR4468

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly and Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly and Assembly UENR0131

C15/C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly and Assembly UENR0132 Procedure

What code are you troubleshooting? __________

Follow the correct troubleshooting procedure. Reference Table 1 for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document those results in Tables 2, 3, and 4.Tables

Table 2

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test Pass / Fail

3 DEF Concentration Test % at 20° C (68° F)

Illustration 1 g06175415

Table 3

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Result Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injectors from the applicable harness.

3 Inspect the connector for damage and debris.

4 Measure the temperature of the injector (aluminum body). C

5 Connect two 398-4987 Probes to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector. Reference Illustration 1 for example.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Aftertreatment SCR System Dosing - Test"

2 Remove the injector from the DPF outlet.

3 Take a photograph of the DEF injector mount on the DPF outlet and the tip of the DEF injector.

4 Install the injector on the beaker.

5 Run the DEF System Dosing Accuracy test through Cat® Electronic Technician (ET).

6 Use the beaker to measure the amount of fluid from the dosing test. ml

7 Repeat the test to verify consistency. ml

8 Install the injector back onto the DPF outlet.

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.DEF injectors are being replaced in the field and returned to Caterpillar for testing. Results of the testing are finding a large portion of the returned DEF injectors are found to be fault not repeated.This form is to be used and filled out in any case that a DEF injector is being replaced.The DEF injector troubleshooting return form needs to be completed and included within failed part returns documenting what was found that led to DEF injector replacement. Attach the photos of DEF injector tip and mount area along with a Product Status Report to the SIMS claim.References

Table 1

Engine Publication Type Media Number

C7.1 Troubleshooting UENR0668

Testing and Adjusting UENR4467

Disassembly and Assembly UENR4468

C9.3 Troubleshooting UENR0978

Testing and Adjusting UENR3402

Disassembly and Assembly UENR0130

C13 Troubleshooting UENR0955

Testing and Adjusting UENR4302

Disassembly and Assembly UENR0131

C15/C18 Troubleshooting UENR0955

Testing and Adjusting UENR3351

Disassembly and Assembly UENR0132 Procedure

What code are you troubleshooting? __________

Follow the correct troubleshooting procedure. Reference Table 1 for correct media number to use.

When troubleshooting procedure requests the DEF quality check, DEF injector resistance measurement, or Dosing Accuracy Test, document those results in Tables 2, 3, and 4.Tables

Table 2

DEF Quality Results

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Diesel Exhaust Fluid Quality - Test"

2 DEF Contamination Test Pass / Fail

3 DEF Concentration Test % at 20° C (68° F)

Illustration 1 g06175415

Table 3

Injector Resistance Measurement

Step Instruction Completed (Yes/No) Result Comments Units

1 Turn the keyswitch to the OFF position. Allow 2 minutes to elapse before proceeding.

2 Disconnect the DEF injectors from the applicable harness.

3 Inspect the connector for damage and debris.

4 Measure the temperature of the injector (aluminum body). C

5 Connect two 398-4987 Probes to the DEF injector. The connectors must be used to prevent damage to the DEF injector connector. Reference Illustration 1 for example.

6 Measure the resistance of the DEF injector. Ohms

Table 4

Dosing Accuracy Test

Step Instruction Completed (Yes/No) Result Comments Units

1 Follow the Testing and Adjusting procedure for "Aftertreatment SCR System Dosing - Test"

2 Remove the injector from the DPF outlet.

3 Take a photograph of the DEF injector mount on the DPF outlet and the tip of the DEF injector.

4 Install the injector on the beaker.

5 Run the DEF System Dosing Accuracy test through Cat® Electronic Technician (ET).

6 Use the beaker to measure the amount of fluid from the dosing test. ml

7 Repeat the test to verify consistency. ml

8 Install the injector back onto the DPF outlet.