Information injection-pump assembly

ZEXEL

106961-1879

1069611879

ISUZU

1156021918

1156021918

Rating:

Service parts 106961-1879 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/22.1(225)

15.

NOZZLE SET

Include in #1:

106961-1879

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1879

1069611879

ISUZU

1156021918

1156021918

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

85.6

84.1

87.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.9+-0.5

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

95.9

91.9

99.9

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

137

137

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Injection quantity adjustment_05

Adjusting point

F

Rack position

8.1

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

94.8

90.8

98.8

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Timer adjustment

Pump speed

r/min

750+50

Advance angle

deg.

0

0

0

Load

1/4

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1000+50

Advance angle

deg.

1

0.5

1

Load

3/4

Timer adjustment_03

Pump speed

r/min

(1075)

Advance angle

deg.

1

0.5

1

Load

4/4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

3

2.7

3.3

Load

4/4

Timer adjustment_05

Pump speed

r/min

1250

Advance angle

deg.

6

5.5

6.5

Load

4/4

Remarks

Finish

Finish

Test data Ex:

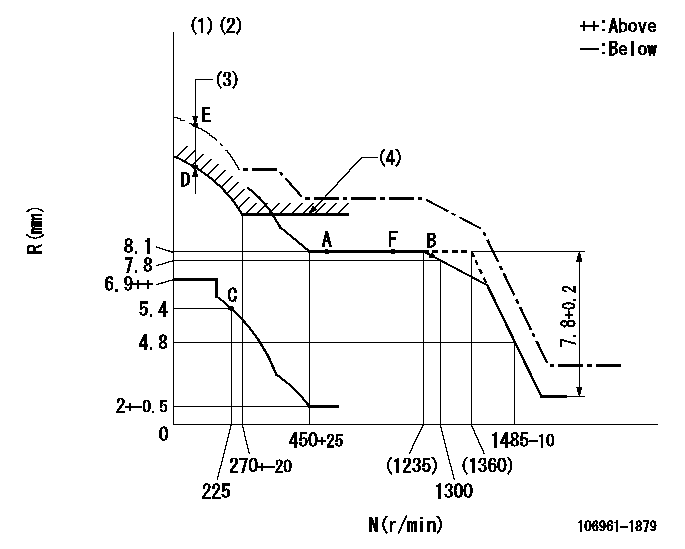

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Supplied with damper spring not set.

(2)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(3)At excess fuel lever operation: not exceeding EXL

(4)Excess fuel setting for starting: SXL

----------

EXL=2mm SXL=9.2+-0.1mm

----------

----------

EXL=2mm SXL=9.2+-0.1mm

----------

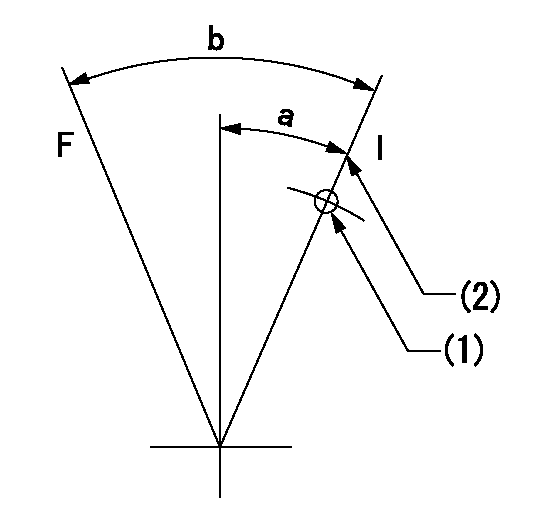

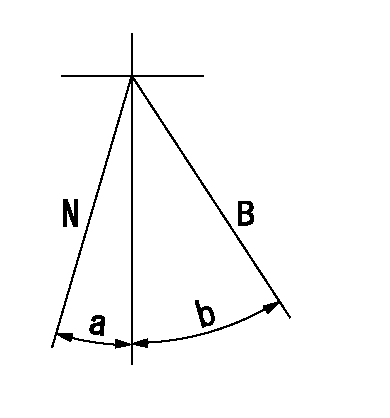

Speed control lever angle

F:Full speed

----------

----------

a=9deg+-5deg

----------

----------

a=9deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=70mm

----------

a=15deg+-5deg b=33deg+-3deg

----------

aa=70mm

----------

a=15deg+-5deg b=33deg+-3deg

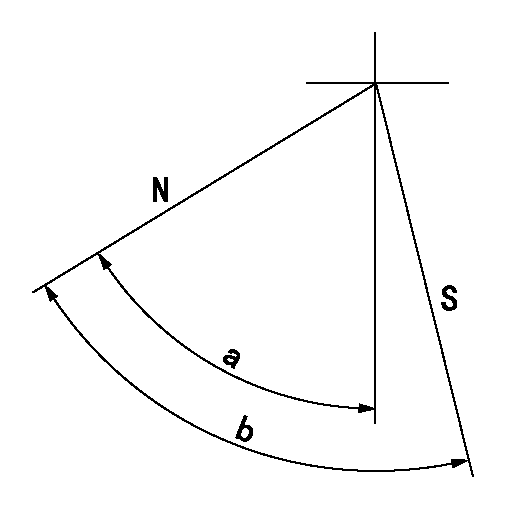

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

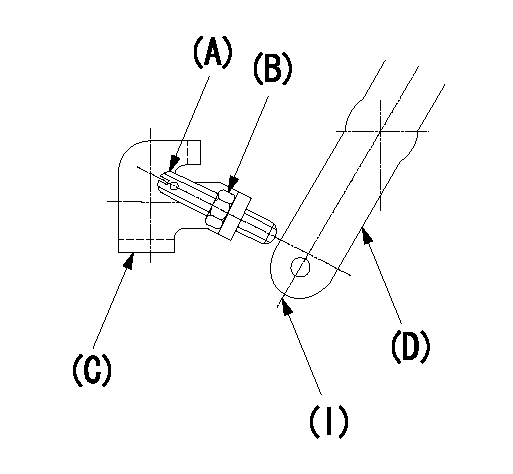

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

0000001601 LEVER

(A) stopper screw

Locknut B

(C) Bracket

(D) Load lever

(I) Idle position

Mechanical autocruise load lever setting procedure

(1)Set the stopper screw after injection pump adjustment.

(2)Set the load lever (D) in the idle position and screw in the stopper screw (A) until it contacts lever (D).

(3)From the above condition, return screw (A) N turns and fix it using the locknut (B).

----------

N=1~1.5

----------

----------

N=1~1.5

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(170deg)

----------

aa=12deg

----------

a=(170deg)

Information:

Retrofit DPF (Diesel Particulate Filter) System

This Retrofit DPF (Diesel Particulate Filter) System must have the following components:

Diesel Particulate Filter (DPF)

Silencer and/or housing

Clamp and gasket

Flow direction label

Engine tagEngine exhaust flows into the Retrofit DPF System reactor housing through the exhaust inlet. Exhaust flows through the DPF.Non-Unidirectional Requirements

(r) Directional Requirements for Diesel Emission Control Strategies

Every diesel emission control strategy must be installed as designed and specified by the manufacturer. For a diesel emission control strategy comprised of multiple exhaust aftertreatment parts, each aftertreatment part must be installed in the proper order relative to the exhaust flow.

Diesel emission control strategies installed between February 19, 2009, and January 1, 2010.

(A) The diesel emission control strategy must indicate the proper direction of exhaust flow. This exhaust flow indicator will allow the end user or installer to see how to install the device properly.

Diesel emission control strategies installed on or after January 1, 2010.

(A) The proper direction for exhaust to flow through the aftertreatment part of the diesel emission control strategy is to be clearly indicated on the outside surface of the aftertreatment part. The exhaust flow indicator consists of an arrow imprinted on or affixed to the aftertreatment part. The indicator arrow is to be clearly visible and durable.

(B) The aftertreatment part must be constructed such that the part can only be installed into the diesel emission control strategy in one unique direction relative to the exhaust flow. The aftertreatment part cannot be installed in the reversed direction.

(C) A diesel emission control strategy not meeting these requirements may be installed after January 1, 2010, if the diesel emission controls strategy: (1) Has a date of manufacture no later than December 31, 2009, (2) Complies with (r)(1) and (r)(2) above and (3) Is installed no later than December 31 2011.

(D) Except for an aftertreatment part that reduces PM through a physical trapping mechanism, such as a diesel particulate filter, the applicant may request that the Executive Officer waives the requirements that an aftertreatment part indicates the flow direction and have unidirectional construction. In reviewing the request, the Executive Officer may consider all relevant information including, but not limited to, the symmetry of the aftertreatment part, potential for impaired performance as a result of different orientations relative to exhaust flow, and interaction with other parts.Diesel Particulate Filter Operation

The Cat DPF is a catalyzed diesel particulate filter that is designed to reduce emissions of particulate (smoke), carbon monoxide (CO) and hydrocarbons (HC), from diesel engines. Carbon monoxide and hydrocarbon reductions are achieved when the exhaust gases interact with the catalyst on the ceramic filter. The catalyst is impregnated on the walls of the ceramic substrate. As the exhaust gases come in contact with the catalyst, a chemical reaction takes place that oxidizes the gases. The oxidation process turns carbon monoxide into carbon dioxide, and hydrocarbons into water and carbon dioxide.Reduction of Emissions

The Cat DPF is a complete product for reducing carbon monoxide, hydrocarbons, and PM. The filter is catalyzed with a precious-metal catalyst. For CO

This Retrofit DPF (Diesel Particulate Filter) System must have the following components:

Diesel Particulate Filter (DPF)

Silencer and/or housing

Clamp and gasket

Flow direction label

Engine tagEngine exhaust flows into the Retrofit DPF System reactor housing through the exhaust inlet. Exhaust flows through the DPF.Non-Unidirectional Requirements

(r) Directional Requirements for Diesel Emission Control Strategies

Every diesel emission control strategy must be installed as designed and specified by the manufacturer. For a diesel emission control strategy comprised of multiple exhaust aftertreatment parts, each aftertreatment part must be installed in the proper order relative to the exhaust flow.

Diesel emission control strategies installed between February 19, 2009, and January 1, 2010.

(A) The diesel emission control strategy must indicate the proper direction of exhaust flow. This exhaust flow indicator will allow the end user or installer to see how to install the device properly.

Diesel emission control strategies installed on or after January 1, 2010.

(A) The proper direction for exhaust to flow through the aftertreatment part of the diesel emission control strategy is to be clearly indicated on the outside surface of the aftertreatment part. The exhaust flow indicator consists of an arrow imprinted on or affixed to the aftertreatment part. The indicator arrow is to be clearly visible and durable.

(B) The aftertreatment part must be constructed such that the part can only be installed into the diesel emission control strategy in one unique direction relative to the exhaust flow. The aftertreatment part cannot be installed in the reversed direction.

(C) A diesel emission control strategy not meeting these requirements may be installed after January 1, 2010, if the diesel emission controls strategy: (1) Has a date of manufacture no later than December 31, 2009, (2) Complies with (r)(1) and (r)(2) above and (3) Is installed no later than December 31 2011.

(D) Except for an aftertreatment part that reduces PM through a physical trapping mechanism, such as a diesel particulate filter, the applicant may request that the Executive Officer waives the requirements that an aftertreatment part indicates the flow direction and have unidirectional construction. In reviewing the request, the Executive Officer may consider all relevant information including, but not limited to, the symmetry of the aftertreatment part, potential for impaired performance as a result of different orientations relative to exhaust flow, and interaction with other parts.Diesel Particulate Filter Operation

The Cat DPF is a catalyzed diesel particulate filter that is designed to reduce emissions of particulate (smoke), carbon monoxide (CO) and hydrocarbons (HC), from diesel engines. Carbon monoxide and hydrocarbon reductions are achieved when the exhaust gases interact with the catalyst on the ceramic filter. The catalyst is impregnated on the walls of the ceramic substrate. As the exhaust gases come in contact with the catalyst, a chemical reaction takes place that oxidizes the gases. The oxidation process turns carbon monoxide into carbon dioxide, and hydrocarbons into water and carbon dioxide.Reduction of Emissions

The Cat DPF is a complete product for reducing carbon monoxide, hydrocarbons, and PM. The filter is catalyzed with a precious-metal catalyst. For CO