Information injection-pump assembly

ZEXEL

106961-1700

1069611700

Rating:

Service parts 106961-1700 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-138-2

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106961-1700

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1700

1069611700

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

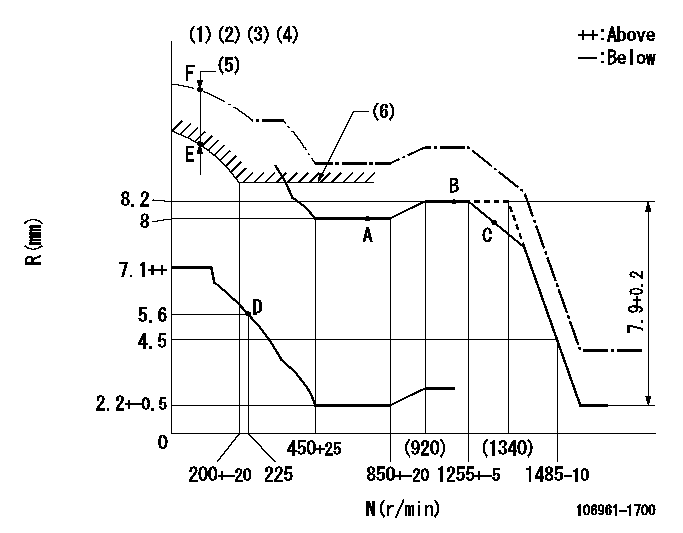

Injection quantity adjustment

Adjusting point

A

Rack position

8

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

83.5

82

85

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.2

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

96.3

94.3

98.3

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.8+-0.5

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

96.8

92.8

100.8

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

125

125

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Supplied with damper spring not set.

(4)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(5)At excess fuel lever operation: not exceeding EXL

(6)Excess fuel setting for starting: SXL

----------

RT=0.8 TH=2.7mm EXL=2mm SXL=9.7+-0.1mm

----------

----------

RT=0.8 TH=2.7mm EXL=2mm SXL=9.7+-0.1mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7.5)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7.5+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(7.5)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7.5+-0.3deg R01=0/4load R02=4/4load

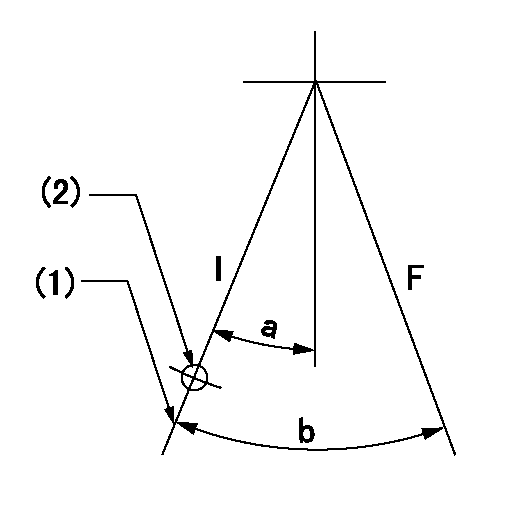

Speed control lever angle

F:Full speed

----------

----------

a=9deg+-5deg

----------

----------

a=9deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=40mm

----------

a=10deg+-5deg b=32deg+-3deg

----------

aa=40mm

----------

a=10deg+-5deg b=32deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(170deg)

----------

aa=13deg

----------

a=(170deg)

Information:

Illustration 1 g01046024

Engine with two turbochargers (1) Inlet valves (2) Exhaust valves (3) Inlet manifold (4) Exhaust manifold (5) Water inlet for the aftercooler (6) Water outlet for the aftercooler (7) Aftercooler (8) Air inlet (9) Exhaust outlet (10) Compressor (11) TurbineThe components of the air inlet and exhaust system control the quality of air and the amount of air that is available for combustion. The components of the air inlet and exhaust system are the following components:

Air cleaner

Turbocharger

Aftercooler

Cylinder head

Valves and valve system components

Piston and cylinder

Inlet manifold

Exhaust manifoldNote: The following description of the operation of the air inlet and exhaust system assumes that the engine is developing boost pressure. Inlet air passes through the air cleaner into the air inlet (8) of the turbocharger compressor wheel (10). The turbocharger will supply more volume of air into the engine. This compressing of the air is referred to as boost. The compressing of air causes the air temperature to rise to about 204 °C (400 °F). As the air flows through the aftercooler (7) the temperature of the compressed air lowers to about 46 °C (115 °F). Cooling of the inlet air causes the air to become more dense. This increases combustion efficiency and this increases horsepower output.From the aftercooler, air enters the inlet manifold (3). Air flow from the inlet manifold (3) into the cylinders is controlled by inlet valves (1). There are two inlet valves and two exhaust valves (2) for each cylinder. The inlet valves open at the top center position before the piston moves toward the bottom center position. This is called the inlet stroke. When the inlet valves open, cooled compressed air from the inlet port enters the cylinder. The inlet valves close as the piston reaches the bottom center position. The piston begins to travel back to the top center position on the compression stroke. The air in the cylinder is compressed to a very high temperature. When the piston is near the end of the compression stroke, fuel is injected into the cylinder and mixes with the air. This causes combustion to start in the cylinder. Once combustion starts, the combustion force pushes the piston toward the bottom center position. This is called the power stroke. The exhaust valves open when the piston moves toward the bottom center position and the exhaust gases are pushed through the exhaust port into exhaust manifold (4) as the piston travels toward top center on the exhaust stroke. The exhaust valves close and the cycle starts again. The complete cycle consists of four strokes:

Inlet

Compression

Power

ExhaustExhaust gases from the exhaust manifold (4) enter the turbine side of the turbocharger. The exhaust gas temperature causes the turbine wheel (11) in the turbocharger to turn. The turbine wheel is connected to the shaft that drives the compressor wheel. Exhaust gases from the turbine wheel exit the turbocharger (9) .Turbocharger

Illustration 2 g01361124

Water cooled turbocharger (8) Air inlet (9) Exhaust outlet (11) Exhaust inlet (12) Compressor housing (13) Compressor wheel (14) Bearing (15) Oil Inlet