Information injection-pump assembly

ZEXEL

106961-1581

1069611581

Rating:

Service parts 106961-1581 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

3.

GOVERNOR

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-163-2

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106961-1581

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1581

1069611581

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-3520

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-9-8-

5-2-11-1

0-3-6-7-

Pre-stroke

mm

4.4

4.37

4.43

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 15 14.75 15.25

Cal 1-4 deg. 15 14.75 15.25

Difference between angles 2

Cal 1-9 deg. 60 59.75 60.25

Cal 1-9 deg. 60 59.75 60.25

Difference between angles 3

Cal 1-8 deg. 75 74.75 75.25

Cal 1-8 deg. 75 74.75 75.25

Difference between angles 4

Cal 1-5 deg. 120 119.75 120.25

Cal 1-5 deg. 120 119.75 120.25

Difference between angles 5

Cyl.1-2 deg. 135 134.75 135.25

Cyl.1-2 deg. 135 134.75 135.25

Difference between angles 6

Cal 1-11 deg. 180 179.75 180.25

Cal 1-11 deg. 180 179.75 180.25

Difference between angles 7

Cal 1-10 deg. 195 194.75 195.25

Cal 1-10 deg. 195 194.75 195.25

Difference between angles 8

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 9

Cal 1-6 deg. 255 254.75 255.25

Cal 1-6 deg. 255 254.75 255.25

Difference between angles 10

Cal 1-7 deg. 300 299.75 300.25

Cal 1-7 deg. 300 299.75 300.25

Difference between angles 11

Cal 1-12 deg. 315 314.75 315.25

Cal 1-12 deg. 315 314.75 315.25

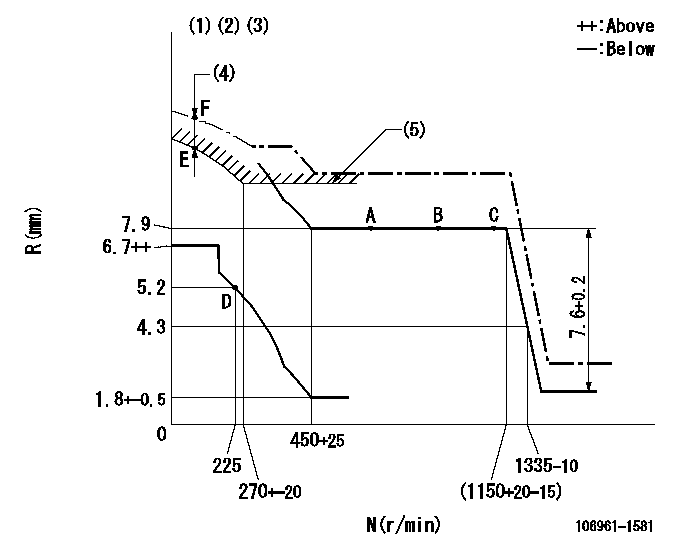

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

87.4

85.9

88.9

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

93.5

89.5

97.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

94.5

90.5

98.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

137

137

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Supplied with damper spring not set.

(2)Supplied with torque spring not set.

(3)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(4)At excess fuel lever operation: not exceeding EXL

(5)Excess fuel setting for starting: SXL

----------

EXL=2mm SXL=9+-0.1mm

----------

----------

EXL=2mm SXL=9+-0.1mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2(mm) N2=800r/min C2=(7.5)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=950++r/min P1=0kPa(0 kgf/cm2) P2=392kPa(4 kgf/cm2) C1=7.5+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2(mm) N2=800r/min C2=(7.5)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=950++r/min P1=0kPa(0 kgf/cm2) P2=392kPa(4 kgf/cm2) C1=7.5+-0.3deg R01=0/4load R02=4/4load

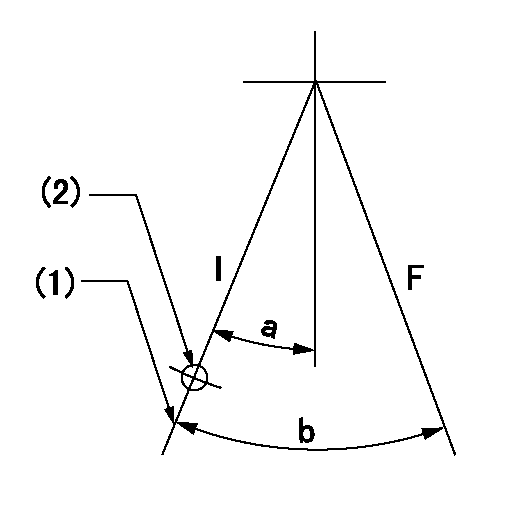

Speed control lever angle

F:Full speed

----------

----------

a=6deg+-5deg

----------

----------

a=6deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

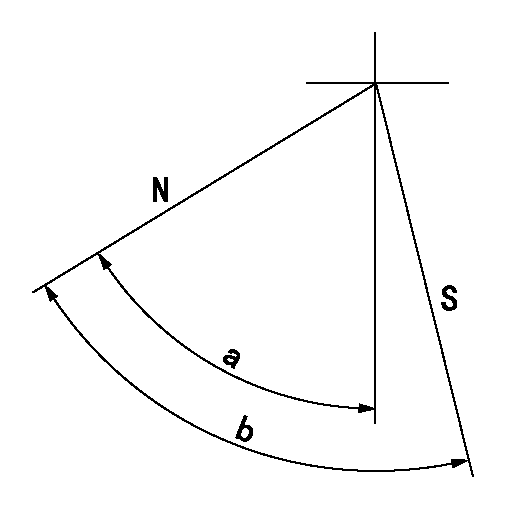

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(170deg)

----------

aa=12deg

----------

a=(170deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Illustration 1 g06201989Certain Cat® Reman 3500 electronic fuel injectors may be marked with incorrect trim codes. Cat Reman 3500 electronic fuel injectors marked with trim code "2755" manufactured between 09 January 2017and 18 April 2017may be affected.The trim code is not correct for every injector. Refer to Illustration 1 for trim code identification. Serial numbers of suspect injectors range from (S/N: 1825569-1880788).Solution

Caterpillar is aware of this problem, but a permanent repair has not been identified. As an interim action, follow the below procedure:

All Reman 3500 electronic fuel injectors marked with trim code "2755" manufactured between 09 January 2017and 18 April 2017are suspect. Refer to Illustration 1.Caterpillar has created a tool which will help to identify injectors labeled with the incorrect trim code. Use the link below to download the file.https://cat.box.com/s/4fwh9nz0lwguh8vomifxj2rapqjc27e9

Enter the injector Serial Number in the spreadsheet downloaded. The spreadsheet will indicate whether the code is ok to use as is, or the spreadsheet will return the correct trim code.

Illustration 2 g06203882

If the trim code is incorrect, the injector must be relabeled. Use an engraving tool to cross out the original (incorrect) trim code (2755) and write the correct trim code on the injector tappet. Refer to Illustration 2.

Illustration 3 g06202000

Mark the box for each part that has been either reworked or verified to be correct, to identify that the parts are good to use. Refer to Illustration 3.

For individual injector replacements in engines, update the ECM with the correct trim code. Injectors must be marked with the correct trim code.Note: Do not return affected parts to Caterpillar. Use the procedure listed above to remark and use existing stock.Note: The issue has been resolved in the factory. Factory stock has been reworked and shipped. Parts in the distribution system are being sorted for return & rework.Note: Injector boxes have been marked with a large green dot to indicate that the injector has been sorted and marked correctly, or the trim code is correct.

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

Illustration 1 g06201989Certain Cat® Reman 3500 electronic fuel injectors may be marked with incorrect trim codes. Cat Reman 3500 electronic fuel injectors marked with trim code "2755" manufactured between 09 January 2017and 18 April 2017may be affected.The trim code is not correct for every injector. Refer to Illustration 1 for trim code identification. Serial numbers of suspect injectors range from (S/N: 1825569-1880788).Solution

Caterpillar is aware of this problem, but a permanent repair has not been identified. As an interim action, follow the below procedure:

All Reman 3500 electronic fuel injectors marked with trim code "2755" manufactured between 09 January 2017and 18 April 2017are suspect. Refer to Illustration 1.Caterpillar has created a tool which will help to identify injectors labeled with the incorrect trim code. Use the link below to download the file.https://cat.box.com/s/4fwh9nz0lwguh8vomifxj2rapqjc27e9

Enter the injector Serial Number in the spreadsheet downloaded. The spreadsheet will indicate whether the code is ok to use as is, or the spreadsheet will return the correct trim code.

Illustration 2 g06203882

If the trim code is incorrect, the injector must be relabeled. Use an engraving tool to cross out the original (incorrect) trim code (2755) and write the correct trim code on the injector tappet. Refer to Illustration 2.

Illustration 3 g06202000

Mark the box for each part that has been either reworked or verified to be correct, to identify that the parts are good to use. Refer to Illustration 3.

For individual injector replacements in engines, update the ECM with the correct trim code. Injectors must be marked with the correct trim code.Note: Do not return affected parts to Caterpillar. Use the procedure listed above to remark and use existing stock.Note: The issue has been resolved in the factory. Factory stock has been reworked and shipped. Parts in the distribution system are being sorted for return & rework.Note: Injector boxes have been marked with a large green dot to indicate that the injector has been sorted and marked correctly, or the trim code is correct.