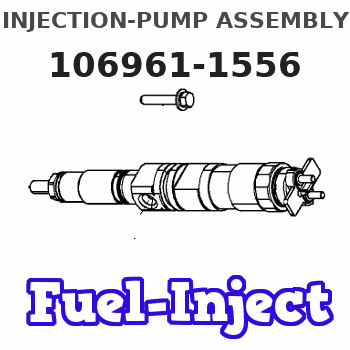

Information injection-pump assembly

ZEXEL

106961-1556

1069611556

ISUZU

1156017309

1156017309

Rating:

Service parts 106961-1556 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-163-2

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106961-1556

as INJECTION-PUMP ASSEMBLY

Cross reference number

Zexel num

Bosch num

Firm num

Name

Information:

Additional Parts Needed for Installation

Fluid Property Sensor Mounting Bracket

A mounting bracket must be fabricated to support the Fluid Property Sensor. Since the kit can be used on a large range of engines in both stationary and machine applications, no universal mounting bracket design is possible. A bracket must be field fabricated to allow mounting of the sensor to a structural component of the machine. Leave room for electrical connection and room at each end for Engine Lubricating Oil line connections.Fittings and Adapters

Due to the large range of engines that this system may be used on, a list of all Engine Lubrication Oil line fittings, sizes, styles, and adapters are not possible. As a starting point, the inlet and outlet of the sensor adapter is a 37 degree Flare for 1" oil lines. This must be adapted to the correct size oil line tubing required for each engine. It is likely that the supply and return fuel lines will be of different sizes. It is recommended that the oil line tubing be new and in good condition. The tubing MUST be clean inside. Any small particles that are carried from the inlet hose through the transducer from the system and dislodge the particles. If hoses are equipped with O-ring fittings, the O-rings must be new.Wiring Diagram

Note: During Installation, it is important to protect wiring in key locations. Key locations are any area where the wiring could be nicked or cut and come in contact with the chassis. Avoid installation practices where there could be excessive flexing, chafing, or cutting of the wiring.

Illustration 1 g06137996

Fluid Property Sensor Wiring Schematic

Installation

Machine Preparation

Move the machine to a smooth, level location, and away from other working machines and personnel.

Lower the implements to the ground.

Stop the engine.

Engage the parking brake for the machine.

Place the disconnect switch in the OFF position.

Follow all LOTO instructions for the machine.Installation of the Fluid Property Sensor

The Fluid Property Sensor must be located on a field fabricated bracket in a location of the installer's choice. When selecting a mounting location, the installer must mount the sensor in an area off the engine to reduce vibration of the sensor as well as accessibility of sensor and electrical connection. Electrical connections should avoid sharp bends at connectors, sharp edges, and chafing surfaces. Harnesses should be supported at no less than 30.48 cm (12 inch) intervals. The Fluid Property Sensor must be installed with the orifice opening in the upright position as shown in Illustration 2.

Illustration 2 g06138010

Fluid Property Sensor Installation

(A) Oil Pump

(B) Oil Filter

(C) Engine Oil Gallery

(D) Isolation Valve

(E) Oil Flow

(F) Fluid Property Sensor Orientation

(G) Oil Reservoir

(H) Oil Strainer

(I) Engine Oil SumpInstallation of the Electrical Harnesses

Note: During installation, it is important to protect wiring in key locations. Key locations are any area where the wiring could be nicked or cut and come in contact with the chassis. Avoid installation practices where there could be excessive flexing, chafing, or cutting of the wiring.

Install the 514-3811 Instl GP-Field (Fluid Property Harness) on Fluid Property Sensor.

Route harness back

Fluid Property Sensor Mounting Bracket

A mounting bracket must be fabricated to support the Fluid Property Sensor. Since the kit can be used on a large range of engines in both stationary and machine applications, no universal mounting bracket design is possible. A bracket must be field fabricated to allow mounting of the sensor to a structural component of the machine. Leave room for electrical connection and room at each end for Engine Lubricating Oil line connections.Fittings and Adapters

Due to the large range of engines that this system may be used on, a list of all Engine Lubrication Oil line fittings, sizes, styles, and adapters are not possible. As a starting point, the inlet and outlet of the sensor adapter is a 37 degree Flare for 1" oil lines. This must be adapted to the correct size oil line tubing required for each engine. It is likely that the supply and return fuel lines will be of different sizes. It is recommended that the oil line tubing be new and in good condition. The tubing MUST be clean inside. Any small particles that are carried from the inlet hose through the transducer from the system and dislodge the particles. If hoses are equipped with O-ring fittings, the O-rings must be new.Wiring Diagram

Note: During Installation, it is important to protect wiring in key locations. Key locations are any area where the wiring could be nicked or cut and come in contact with the chassis. Avoid installation practices where there could be excessive flexing, chafing, or cutting of the wiring.

Illustration 1 g06137996

Fluid Property Sensor Wiring Schematic

Installation

Machine Preparation

Move the machine to a smooth, level location, and away from other working machines and personnel.

Lower the implements to the ground.

Stop the engine.

Engage the parking brake for the machine.

Place the disconnect switch in the OFF position.

Follow all LOTO instructions for the machine.Installation of the Fluid Property Sensor

The Fluid Property Sensor must be located on a field fabricated bracket in a location of the installer's choice. When selecting a mounting location, the installer must mount the sensor in an area off the engine to reduce vibration of the sensor as well as accessibility of sensor and electrical connection. Electrical connections should avoid sharp bends at connectors, sharp edges, and chafing surfaces. Harnesses should be supported at no less than 30.48 cm (12 inch) intervals. The Fluid Property Sensor must be installed with the orifice opening in the upright position as shown in Illustration 2.

Illustration 2 g06138010

Fluid Property Sensor Installation

(A) Oil Pump

(B) Oil Filter

(C) Engine Oil Gallery

(D) Isolation Valve

(E) Oil Flow

(F) Fluid Property Sensor Orientation

(G) Oil Reservoir

(H) Oil Strainer

(I) Engine Oil SumpInstallation of the Electrical Harnesses

Note: During installation, it is important to protect wiring in key locations. Key locations are any area where the wiring could be nicked or cut and come in contact with the chassis. Avoid installation practices where there could be excessive flexing, chafing, or cutting of the wiring.

Install the 514-3811 Instl GP-Field (Fluid Property Harness) on Fluid Property Sensor.

Route harness back