Information injection-pump assembly

ZEXEL

106961-1522

1069611522

Rating:

Service parts 106961-1522 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-163-2

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106961-1522

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1522

1069611522

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4.4

4.37

4.43

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

87.4

85.9

88.9

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

94.5

90.5

98.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

5.2+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

137

137

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0.5

0.3

0.8

Remarks

Measure the actual speed.

Measure the actual speed.

Timer adjustment_03

Pump speed

r/min

(950)

Advance angle

deg.

0.5

0.3

0.8

Timer adjustment_04

Pump speed

r/min

1050

Advance angle

deg.

3

2.7

3.3

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

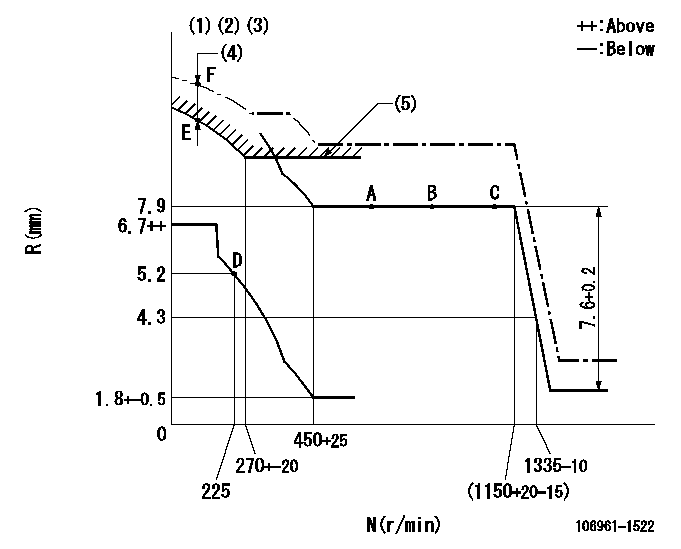

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Supplied with damper spring not set.

(2)Supplied with torque spring not set.

(3)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(4)At excess fuel lever operation: not exceeding EXL

(5)Excess fuel setting for starting: SXL

----------

EXL=2mm SXL=9+-0.1mm

----------

----------

EXL=2mm SXL=9+-0.1mm

----------

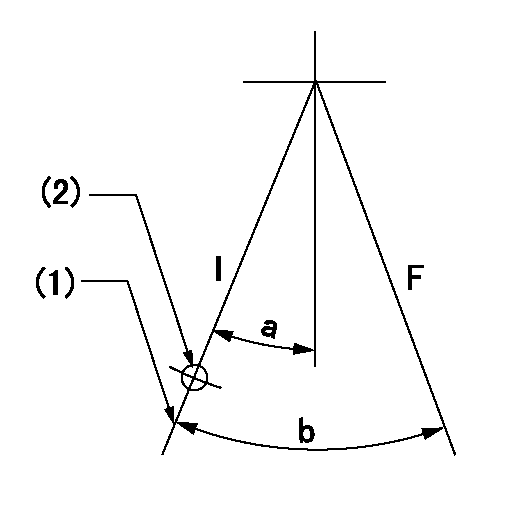

Speed control lever angle

F:Full speed

----------

----------

a=6deg+-5deg

----------

----------

a=6deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

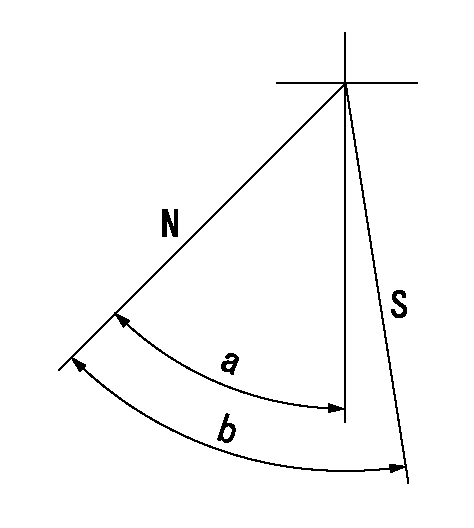

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(170deg)

----------

aa=12deg

----------

a=(170deg)

Information:

Safety Section

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Illustration 1 g00104545Prevent the machine from movement. Park the machine on a level surface.Attach a "Do Not Operate" warning tag or a similar warning tag to the start switch or to the controls before you service the equipment. These warning tags (Special Instruction, SEHS7332) are available from your Caterpillar dealer.Required Parts

Table 1 contains the parts needed to complete the installation of the new DEF filter.Note: Only one DEF filter group is required per engine. Use Table 2 to determine which filter is the appropriate filter for each DEF header. Illustration 2 shows the location of the DEF header part number.

Table 1

Part Number Part Description Qty

378-3187 Diesel Exhaust Fluid Filter Gp 1

423-3251 Connector 1

391-5262 Gasket 1

425-0385 Filter As 1

452-6055 Filter Base As 1

453-1604(1) Diesel Exhaust Fluid Filter Gp 1

453-1605(1) Diesel Exhaust Fluid Filter Gp 1

453-1606(1) Diesel Exhaust Fluid Filter Gp 1

(1) Use Table 2 to choose the correct part that corresponds to the DEF header

Illustration 2 g03745839

(1) Location of DEF heater part number

Table 2

DEF Heater Part Number Required DEF Filter

434-3241 453-1604

434-3242 453-1605

434-3243 453-1606 Installation Procedure

Ensure that the area around the DEF heater is clean and free from debris.

Remove manifold DEF heater from DEF tank. Refer to Disassembly and Assembly, Manifold (DEF Heater) - Remove and Install for the correct procedure.

Illustration 3 g06013988

Typical example

Position filter base assembly (3) to DEF heater (2). Install screws (1) to filter base assembly (3). Tighten the self-tapping screws (1) securely.Note: Each half of the adapter has two small locking tabs that secure to the bottom side of the DEF heater.

Remove existing filter from the pickup pipe on manifold DEF heater. Refer to Disassembly and Assembly, Manifold (DEF Heater) - Remove and Install for the correct procedure.

Install a new filter to the pickup pipe on manifold DEF heater. Refer to Disassembly and Assembly, Manifold (DEF Heater) - Remove and Install for the correct procedure.

Illustration 4 g06013992

Typical example

Position the correct DEF filter (5) to the filter base assembly (3). Install band clamp (4). Tighten the band clamp to a torque

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Illustration 1 g00104545Prevent the machine from movement. Park the machine on a level surface.Attach a "Do Not Operate" warning tag or a similar warning tag to the start switch or to the controls before you service the equipment. These warning tags (Special Instruction, SEHS7332) are available from your Caterpillar dealer.Required Parts

Table 1 contains the parts needed to complete the installation of the new DEF filter.Note: Only one DEF filter group is required per engine. Use Table 2 to determine which filter is the appropriate filter for each DEF header. Illustration 2 shows the location of the DEF header part number.

Table 1

Part Number Part Description Qty

378-3187 Diesel Exhaust Fluid Filter Gp 1

423-3251 Connector 1

391-5262 Gasket 1

425-0385 Filter As 1

452-6055 Filter Base As 1

453-1604(1) Diesel Exhaust Fluid Filter Gp 1

453-1605(1) Diesel Exhaust Fluid Filter Gp 1

453-1606(1) Diesel Exhaust Fluid Filter Gp 1

(1) Use Table 2 to choose the correct part that corresponds to the DEF header

Illustration 2 g03745839

(1) Location of DEF heater part number

Table 2

DEF Heater Part Number Required DEF Filter

434-3241 453-1604

434-3242 453-1605

434-3243 453-1606 Installation Procedure

Ensure that the area around the DEF heater is clean and free from debris.

Remove manifold DEF heater from DEF tank. Refer to Disassembly and Assembly, Manifold (DEF Heater) - Remove and Install for the correct procedure.

Illustration 3 g06013988

Typical example

Position filter base assembly (3) to DEF heater (2). Install screws (1) to filter base assembly (3). Tighten the self-tapping screws (1) securely.Note: Each half of the adapter has two small locking tabs that secure to the bottom side of the DEF heater.

Remove existing filter from the pickup pipe on manifold DEF heater. Refer to Disassembly and Assembly, Manifold (DEF Heater) - Remove and Install for the correct procedure.

Install a new filter to the pickup pipe on manifold DEF heater. Refer to Disassembly and Assembly, Manifold (DEF Heater) - Remove and Install for the correct procedure.

Illustration 4 g06013992

Typical example

Position the correct DEF filter (5) to the filter base assembly (3). Install band clamp (4). Tighten the band clamp to a torque