Information injection-pump assembly

ZEXEL

106961-1497

1069611497

ISUZU

1156027380

1156027380

Rating:

Service parts 106961-1497 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/22.1(225)

15.

NOZZLE SET

Include in #1:

106961-1497

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1497

1069611497

ISUZU

1156027380

1156027380

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-3520

Overflow valve opening pressure (drive side)

kPa

255

221

289

Overflow valve opening pressure (drive side)

kgf/cm2

2.6

2.25

2.95

Overflow valve (governor side)

134424-2720

Overflow valve opening pressure (governor side)

kPa

255

221

289

Overflow valve opening pressure (governor side)

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

B

Rack position

8.1

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

85.6

84.1

87.1

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.9+-0.5

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

95.9

91.9

99.9

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

5.4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8

6.6

9.4

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_04

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

137

137

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Injection quantity adjustment_05

Adjusting point

G

Rack position

8.1

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

94.8

90.8

98.8

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Supplied with damper spring not set.

(2)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(3)At excess fuel lever operation: not exceeding EXL

(4)Excess fuel setting for starting: SXL

----------

EXL=2mm SXL=9.2+-0.1mm

----------

----------

EXL=2mm SXL=9.2+-0.1mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7deg) t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(7deg) t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4load R02=4/4load

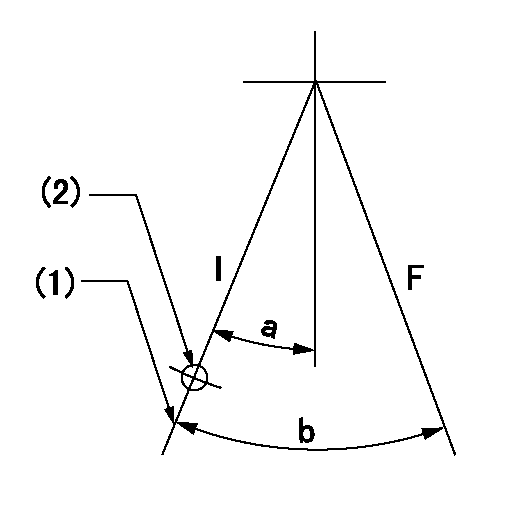

Speed control lever angle

F:Full speed

----------

----------

a=9deg+-5deg

----------

----------

a=9deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

----------

aa=35mm

----------

a=10deg+-5deg b=33deg+-3deg

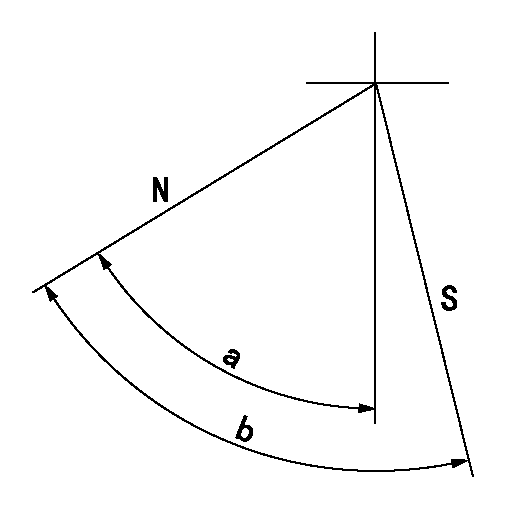

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=12deg

----------

a=(170deg)

----------

aa=12deg

----------

a=(170deg)

Information:

Failure to follow these oil recommendations can cause shortened engine service life due to deposits and/or excessive wear.

Total Base Number (TBN) and Fuel Sulfur Levels for Direct Injection (DI) Diesel Engines

The Total Base Number (TBN) for an oil depends on the fuel sulfur level. For direct injection engines that use distillate fuel, the minimum TBN must be 10 times the fuel sulfur level. The TBN is determined by the "ASTM D2896" procedure. The minimum TBN of the oil is 5 regardless of a low fuel sulfur level. Illustration 1 demonstrates the TBN.

Illustration 1 g00104890

(Y) TBN by "ASTM D2896"

(X) Percentage of fuel sulfur by weight

(1) TBN of new oil

(2) Change the used oil when the TBN reaches this level. Use the following guidelines for fuel sulfur levels that exceed 1.5 percent:

Choose an oil with the highest TBN that meets one of these classifications:

API CG-4

API CH-4

API CI-4Note: API CH-4 oils and API CI-4 oils are acceptable if the requirements of Caterpillar's ECF-1 (Engine Crankcase Fluid specification-1) are met. CH-4 oils and CI-4 oils that have not met the requirements of Caterpillar's ECF-1 Specification may cause reduced engine life.

Reduce the oil change interval. Base the oil change interval on the oil analysis. Ensure that the oil analysis includes the condition of the oil and a wear metal analysis. Excessive piston deposits can be produced by an oil with a high TBN. These deposits can lead to a loss of control of the oil consumption and to the polishing of the cylinder bore.

Operating Direct Injection (DI) diesel engines with fuel sulfur levels over 1.0 percent may require shortened oil change intervals in order to help maintain adequate wear protection.

Lubricant Viscosity Recommendations for Direct Injection (DI) Diesel Engines

The proper SAE viscosity grade of oil is determined by the minimum ambient temperature during cold engine start-up, and the maximum ambient temperature during engine operation. Refer to Table 1 (minimum temperature) in order to determine the required oil viscosity for starting a cold engine.Refer to Table 1 (maximum temperature) in order to select the oil viscosity for engine operation at the highest ambient temperature that is anticipated.Note: Generally, use the highest oil viscosity that is available to meet the requirement for the temperature at start-up.If ambient temperature conditions at engine start-up require the use of multigrade SAE 0W oil, SAE 0W-40 viscosity grade is generally preferred over SAE 0W-20 or SAE 0W-30.Note: SAE 10W-30 is the preferred viscosity grade for the following diesel engines when the ambient temperature is above −18 °C (0 °F), and below 40 °C (104 °F).

C7

C-9

C9

3116

3126When an engine is started and an engine is operated in ambient temperatures below −20 °C (−4 °F), use multigrade oils that are capable of flowing in low temperatures.These oils have lubricant viscosity grades of SAE 0W or SAE 5W.When an engine is started and operated in ambient temperatures below −30 °C (−22 °F), use a synthetic base stock multigrade oil with a 0W viscosity grade or with a 5W viscosity grade. Use an oil with a