Information injection-pump assembly

ZEXEL

106961-1307

1069611307

ISUZU

1156013975

1156013975

Rating:

Service parts 106961-1307 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

15.7(160)/22.1(225)

15.

NOZZLE SET

Include in #1:

106961-1307

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1307

1069611307

ISUZU

1156013975

1156013975

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4.4

4.37

4.43

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

87.2

85.7

88.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

102.5

100.5

104.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.2+-0.5

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

98.5

94.5

102.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.9+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

8.2

6.8

9.6

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

133

133

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Timer adjustment

Pump speed

r/min

900+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1200

Advance angle

deg.

6.5

6

7

Remarks

Finish

Finish

Test data Ex:

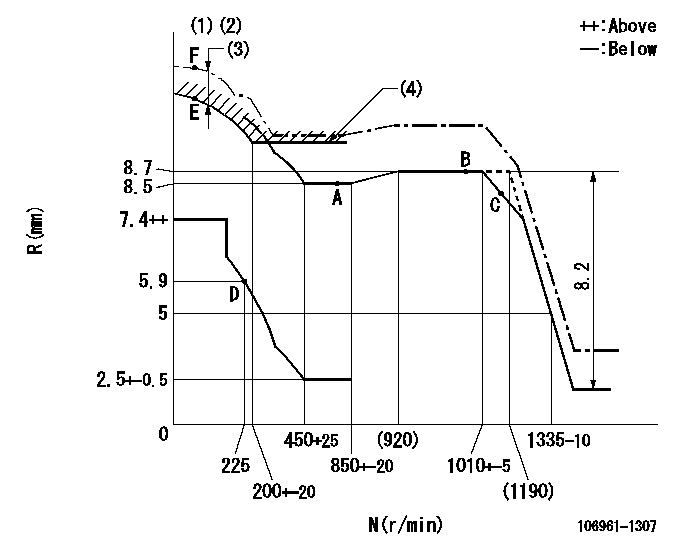

Governor adjustment

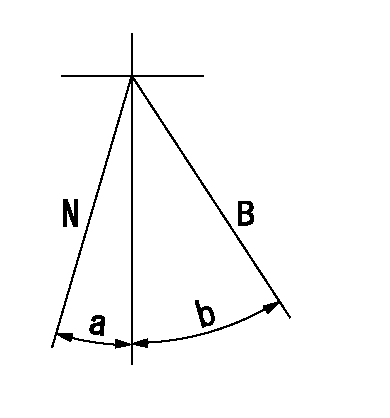

N:Pump speed

R:Rack position (mm)

(1)Supplied with damper spring not set.

(2)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(3)At excess fuel lever operation: not exceeding EXL

(4)Excess fuel setting for starting: SXL

----------

EXL=1.5mm SXL=10.2+-0.1mm

----------

----------

EXL=1.5mm SXL=10.2+-0.1mm

----------

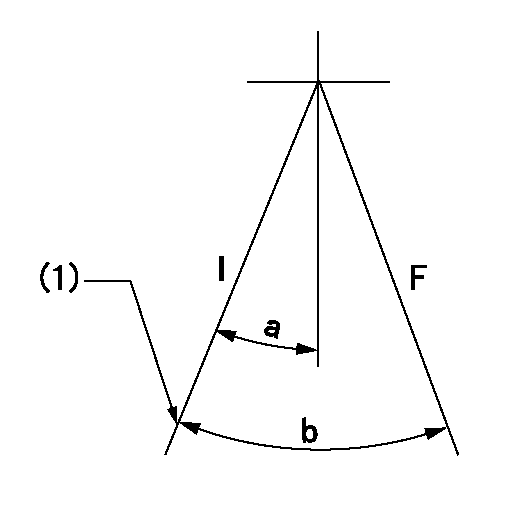

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=32deg+-3deg

----------

----------

a=10deg+-5deg b=32deg+-3deg

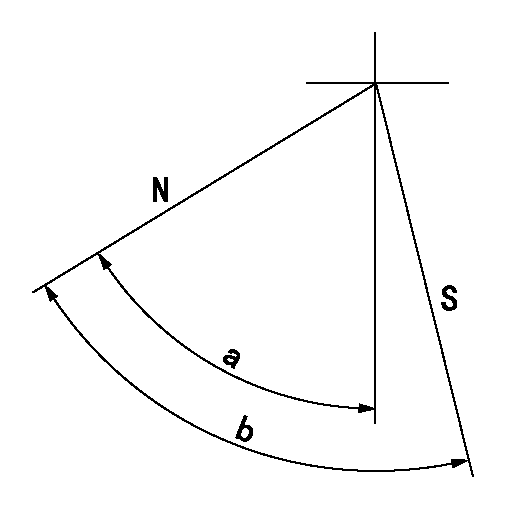

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=60deg+-5deg b=73deg+-5deg

----------

----------

a=60deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(170deg)

----------

aa=13deg

----------

a=(170deg)

Information:

Illustration 1 g00564355

7W-2743 Electronic Speed Switch (ESS)

(1) Push button for Overspeed Verification

(2) Reset button

(3) Overspeed indicator lamp

(4) Seal screw plug for adjusting the engine overspeed

(5) Seal screw plug for adjusting the crank terminate speed

(6) Seal screw plug for adjusting the oil step pressure speed setting The oil step speed calibration increases the oil step speed setting or the oil step speed calibration decreases the oil step speed setting. Refer to the Speed Specification Chart in order to find the oil step speed that is equal to the engine rpm when the engine is running.

Remove the lockwire and the seal from seal screw plug (6). Remove seal screw plug (6) from the access hole for the oil step speed adjusting screw.

Use a small screwdriver to lightly turn the oil step speed adjusting screw in the direction of the "MAX" arrow or the clockwise direction. Turn the screw twenty times. The oil step speed adjusting screw will vary the setting of a potentiometer that is inside of the ESS. The oil step speed adjusting screw will not cause damage to the potentiometer. Also, the screw can not be removed if the screw is turned in the wrong direction.

Connect a voltmeter with the positive lead at terminal (ESS-13) and the negative lead at (ESS-5). Use a 6V-7070 Digital Multimeter or a voltmeter with the same accuracy. Measure the voltage.

For a specific engine rating, find the engine rpm in the column for the oil step speed setting in the Speed Specification Chart. Run the engine at the rpm that is specified in the table.

While the engine is running, look into the hole for the adjustment of the oil step speed. A red indicator lamp should be lighted. A positive voltage should be observed on the multimeter 9 seconds after the indicator lamp is lighted. Turn the oil step speed adjusting screw clockwise until the indicator lamp turns off. The oil step speed setting is above the present rpm of the engine. Slowly turn the oil step speed adjusting screw counterclockwise until the indicator lamp is lighted. After a 9 second delay, a positive voltage should be observed on the multimeter. This position is the correct setting for the oil step speed.

Install seal screw plug (6) in the access hole for the oil step speed adjusting screw. Tighten the screw to a torque of 0.20 0.03 N m (1.8 .3 lb in). Install the lockwire and the seal if the overspeed calibration and the crank terminate speed calibration are also complete.