Information injection-pump assembly

ZEXEL

106961-1040

1069611040

ISUZU

1156014561

1156014561

Rating:

Service parts 106961-1040 INJECTION-PUMP ASSEMBLY:

1.

_

6.

COUPLING PLATE

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-138-2

12.

Open Pre:MPa(Kqf/cm2)

15.7{160}/22.1{225}

15.

NOZZLE SET

Include in #1:

106961-1040

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-1040

1069611040

ISUZU

1156014561

1156014561

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-8-7-6-

5-4-3-10

-9-2

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-8 deg. 27 26.75 27.25

Cal 1-8 deg. 27 26.75 27.25

Difference between angles 2

Cal 1-7 deg. 72 71.75 72.25

Cal 1-7 deg. 72 71.75 72.25

Difference between angles 3

Cal 1-6 deg. 99 98.75 99.25

Cal 1-6 deg. 99 98.75 99.25

Difference between angles 4

Cal 1-5 deg. 144 143.75 144.25

Cal 1-5 deg. 144 143.75 144.25

Difference between angles 5

Cal 1-4 deg. 171 170.75 171.25

Cal 1-4 deg. 171 170.75 171.25

Difference between angles 6

Cal 1-3 deg. 216 215.75 216.25

Cal 1-3 deg. 216 215.75 216.25

Difference between angles 7

Cal 1-10 deg. 243 242.75 243.25

Cal 1-10 deg. 243 242.75 243.25

Difference between angles 8

Cal 1-9 deg. 288 287.75 288.25

Cal 1-9 deg. 288 287.75 288.25

Difference between angles 9

Cyl.1-2 deg. 315 314.75 315.25

Cyl.1-2 deg. 315 314.75 315.25

Injection quantity adjustment

Adjusting point

A

Rack position

8.5

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

89.8

88.3

91.3

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

8.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

105.7

103.7

107.7

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.5+-0.5

Pump speed

r/min

1300

1300

1300

Average injection quantity

mm3/st.

108

104

112

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

14.5

13.1

15.9

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_05

Adjusting point

F

Rack position

-

Pump speed

r/min

150

150

150

Average injection quantity

mm3/st.

135

135

Fixing the lever

*

Remarks

When manual lever is on the boost side

When manual lever is on the boost side

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Supply solenoid operating voltage DC24V and move the solenoid body so that the excess lever reaches the excess position at the solenoid's maximum stroke.

(2)Supplied with damper spring not set.

(3)At excess fuel lever operation: not exceeding EXL

(4)Excess fuel setting for starting: SXL

----------

EXL=1.5mm SXL=10.2+-0.1mm

----------

----------

EXL=1.5mm SXL=10.2+-0.1mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7.5)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7.5+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(7.5)deg t1=1.5--sec. t2=1.5--sec.

----------

N1=1100++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7.5+-0.3deg R01=0/4load R02=4/4load

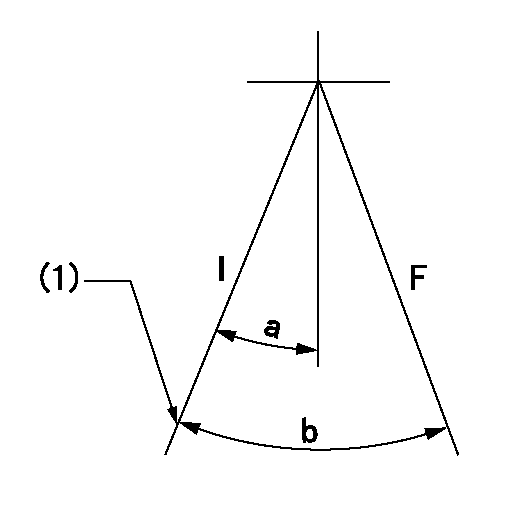

Speed control lever angle

F:Full speed

----------

----------

a=10deg+-5deg

----------

----------

a=10deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=32deg+-3deg

----------

----------

a=10deg+-5deg b=32deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=36deg+-5deg b=73deg+-3deg

----------

----------

a=36deg+-5deg b=73deg+-3deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(5deg) b=(24deg)

----------

----------

a=(5deg) b=(24deg)

Timing setting

(1)Pump vertical direction

(2)Position of "Z" mark at the No 1 cylinder's beginning of injection (governor side)

(3)B.T.D.C.: aa

(4)-

----------

aa=13deg

----------

a=(170deg)

----------

aa=13deg

----------

a=(170deg)

Information:

PROBLEM

On certain C175-16 and C175-20 Generator Sets the 276-1242 4 pin connector that connects the engine harness to the individual cylinder injector harnesses may not be fully latched do to a damaged connector locking tab.

AFFECTED PRODUCT

Model Identification Number

C175-16 WYB00649-00652, 656, 664-665, 1231-1232, 1237, 1241, 1243, 1249, 1253-1254, 1413, 1417, 1424, 1426, 1431, 1434, 1436, 1438, 1476, 1478-1484, 1508, 1564, 1566, 1569-1570, 1573-1574, 1578, 1610, 1612, 1614, 1622, 1625, 1627, 1630, 1825-1826, 1840-1841, 1846-1853, 1857-1860, 1862-1863, 1869-1871, 1873, 1876-1878, 1885, 1888-1891, 1895, 1899, 1904-1909, 1911, 1914-1920, 1925-1927, 1929, 1931-1932, 1936-1940, 1954, 1956, 1958, 2075, 2084, 2087-2088, 2091-2092, 2095-2096, 2098, 2100-2105, 2108-2109, 2112-2113, 2115-2116, 2118, 2127-2129, 2136-2142, 2179, 2182-2185, 2189, 2192-2193, 2195-2196, 2198, 2200, 2203, 2206-2209, 2214, 2227, 2229, 2232-2233, 2244, 2246, 2248-2257, 2332, 2337, 2342, 2352-2353, 2355-2356, 2359, 2362-2364, 2370-2371, 2416, 2437, 2470, 2475, 2479, 2481, 2493, 2500

C175-20 BXR01781, 1798-1807, 1809, 1826, 1828, 1944-1950, 1953-1956, 1959-1960, 1962, 2013-2014, 2026-2027, 2029, 2036, 2042-2046, 2048-2050, 2055-2058

PARTS NEEDED

Qty

Part Number Description

1 4C6389 TUBING-HEAT SHRI

1 1134630 RECEPTACLE AS

1 2300940 SEAL-PIP

1 2761242 KIT-PLUG CONN

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 1% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

1. Inspect 276-1242 4 pin engine harness connector and check the connector locking tab for proper engagement with injector harness receptacle. Image 1 is a damaged locking tab. Image 2 is a good locking tab. If locking tab is found to be damage proceed with replacement.

2. Disconnect the 276-1242 4 pin engine harness connector from the 113-4630 injector harness receptacle at the cylinder head.

3. Remove and replace 276-1242 4 pin connector with new. Insure to reinstall 4C-6389 heat shrink on the connector.

4. Inspect the inside of 113-4630 injector harness receptacle mounted on cylinder head for debris, damage, or paint. If debris, damage, or paint is present, remove and replace 113-4630 injector harness receptacle with new.

Note: Always use a new valve cover gasket if removal of valve cover is required.

5. Reconnect new 276-1242 4 pin engine harness connector to the new 113-4630 injector harnesses receptacle. Insure the connector is fully seated, audible click is heard, lock tab in the proper position, and connector cannot be pulled out.

Image1

Image2

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-600 hrs,

0-45 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 1.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.