Information injection-pump assembly

ZEXEL

106961-0200

1069610200

NISSAN-DIESEL

1670097016

1670097016

Rating:

Service parts 106961-0200 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-97012

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106961-0200

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106961-0200

1069610200

NISSAN-DIESEL

1670097016

1670097016

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

10-9-4-3

-6-5-8-7

-2-1

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 10-9 deg. 45 44.5 45.5

Cal 10-9 deg. 45 44.5 45.5

Difference between angles 2

Cal 10-4 deg. 72 71.5 72.5

Cal 10-4 deg. 72 71.5 72.5

Difference between angles 3

Cal 10-3 deg. 117 116.5 117.5

Cal 10-3 deg. 117 116.5 117.5

Difference between angles 4

Cal 10-6 deg. 144 143.5 144.5

Cal 10-6 deg. 144 143.5 144.5

Difference between angles 5

Cal 10-5 deg. 189 188.5 189.5

Cal 10-5 deg. 189 188.5 189.5

Difference between angles 6

Cal 10-8 deg. 216 215.5 216.5

Cal 10-8 deg. 216 215.5 216.5

Difference between angles 7

Cal 10-7 deg. 261 260.5 261.5

Cal 10-7 deg. 261 260.5 261.5

Difference between angles 8

Cal 10-2 deg. 288 287.5 288.5

Cal 10-2 deg. 288 287.5 288.5

Difference between angles 9

Cal 10-1 deg. 333 332.5 333.5

Cal 10-1 deg. 333 332.5 333.5

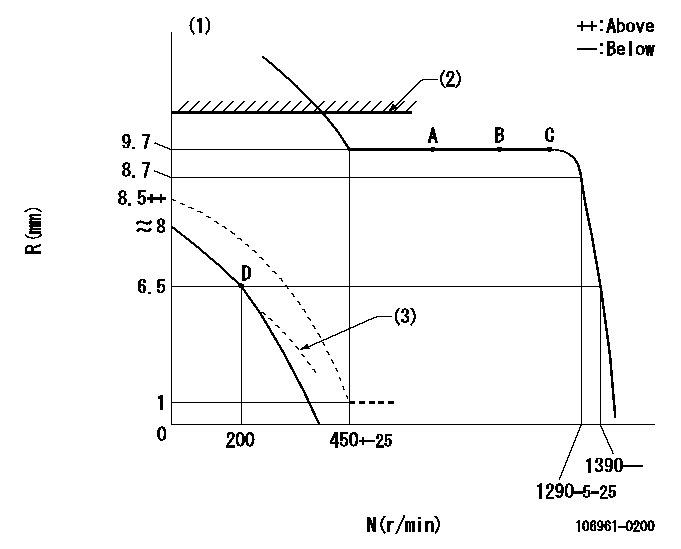

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

116

115

117

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

117

114

120

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

9.7

Pump speed

r/min

1200

1200

1200

Average injection quantity

mm3/st.

121.5

117.5

125.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.5+-0.5

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

10

8

12

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

600

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

750

Advance angle

deg.

0.8

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.7

1.2

2.2

Timer adjustment_04

Pump speed

r/min

1250+-25

Advance angle

deg.

4

3.3

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)After completing adjustment of the broken line, set the lever at the unbroken line position.

(2)Rack limit using the stop lever: R1

(3)Beginning of damper spring operation: DL

----------

R1=11.2+0.2mm DL=5.5-0.2mm

----------

----------

R1=11.2+0.2mm DL=5.5-0.2mm

----------

0000000901

F:Full load

I:Idle

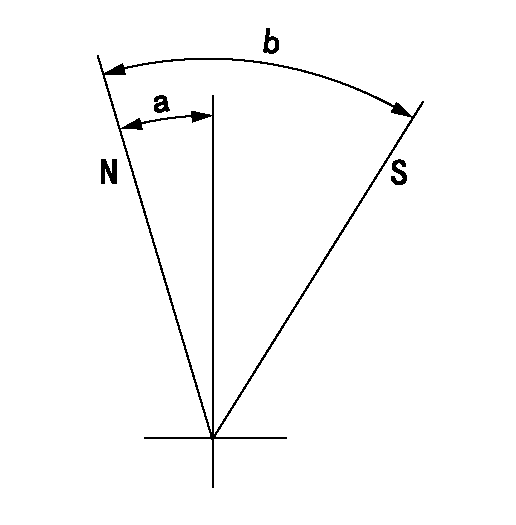

(1)Stopper bolt setting

----------

----------

a=12deg+-5deg b=19deg+-3deg

----------

----------

a=12deg+-5deg b=19deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=12deg+-5deg b=33deg+-3deg

----------

----------

a=12deg+-5deg b=33deg+-3deg

Information:

Guidelines For Reusable Parts; Valves And Valve Springs, SEBF8002 and SEBF8034 have the procedure and specifications necessary for checking used valves and valve springs.(1) 4W2471 Spring for valves (outer) (new): Length under test force ... 53.24 mm (2.096 in)Test force ... 245 24 N (55 5 lb)Use again minimum load at length under test force ... 211 N (48 lb)Length of spring at valve open position ... 39.0 mm (1.54 in)Use again minimum load at valve open position ... 755 N (170 lb)Free length after test ... 59.5 mm (2.34 in)Outside diameter ... 37.31 mm (1.469 in)Spring must not be bent more than ... 2.10 mm (.083 in)(1) 4W2472 Spring for valves (inner) (new): Length under test force ... 50.24 mm (1.978 in)Test force ... 178 18 N (40 4 lb)Use again minimum load at length under test force ... 155 N (35 lb)Length of spring at valve open position ... 36.0 mm (1.42 in)Use again minimum load at valve open position ... 321 N (72 lb)Free length after test ... 65.7 mm (2.60 in)Outside diameter ... 25.13 mm (.989 in)Spring must not be bent more than ... 2.30 mm (.091 in)(2) Height to top of valve guide ... 27.2 .8 mm (1.07 .03 in)(3) Diameter of valve stem (new) ... 9.441 .01 mm (.3717 .0004 in)Use again minimum diameter of valve stems:Exhaust ... 9.408 mm (.3704 in)Inlet ... 9.408 mm (.3704 in)Bore in valve guide with guide installed in the head (new) ... 9.487 0.025 mm (.3735 .0010 in)Use again dimension for valve guide bore ... 9.538 mm (.3755 in)(4) Diameter of valve head: Exhaust valve ... 41.81 0.13 mm (1.646 .005 in)Inlet valve ... 44.98 0.13 mm (1.771 .005 in)(5) Angle of inlet valve face ... 29 1/4 1/4 degreesAngle of exhaust valve face ... 44 1/4 1/4 degrees (6) Depth of bore in head for valve seat insert ... 13.01 0.35 mm (.512 .014 in)(7) Diameter of valve seat insert for inlet valve ... 46.025 0.013 mm (1.8120 .0005 in) Bore in head for valve seat insert for inlet valve ... 45.949 0.025 mm (1.8090 .0010 in)Diameter of valve seat insert for exhaust valve ... 42.850 0.013 mm (1.6870 .0005 in)Bore in head for valve seat insert for exhaust valve ... 42.774 0.025 mm (1.6840 .0010 in)(8) Angle of face of inlet valve seat insert ... 30 1/4 1/2 degreesAngle of face of exhaust valve seat insert ... 44 3/4 1/2 degrees(9) Dimension from end of closed valve to machined face of head. Maximum permissible dimension:Below (recessed from) machined face ... 1.22 mm (.048 in)Above (extended from) machined face ... 0.20